Product Description

Product Description

Product Type | Round/Square/Hexagonal Bar&Rod | |||

| Surface | Black or Bright or Pickling White | |||

| Standard | SUS, AISI, DIN | |||

| Manufacture Technique | Hot Rolling, Cold-drawing | |||

| Diameter | 5~500mm | |||

| Length | As Per Client's Requirements. | |||

| Diameter Tolerance | H7 H9 H10 H11 | |||

| Material Standard | Nickel Alloy | Alloy 825 Incoloy 825UNS N08825 | ||

| ASTM/ASME SB 408 | Alloy 800HT Incoloy 800HT/UNS N088ASTM/ASME SB 42511, Alloy 800/Incoloy 800/UNS N08800, Alloy 800H/Incoloy 800H/UNS N08810 | |||

| ASTM/ASME SB 649 | Alloy 925/Incoloy 925/UNS N09925 Alloy 926/Incoloy 926/UNS N08926 Alloy 31/UNS N08031 | |||

| ASTM/ASME SB 166 | Alloy 600/Inconel 600/UNS N06600 Alloy 601/Inconel 601/UNS N06601 | |||

| ASTM/ASME SB160 | Alloy 200/UNS N02200 Alloy 201/UNS N02201 | |||

| ASTM/ASME SB 472 | Hastelloy C-276/UNS N10276 Alloy 926/Incoloy 926/UNS N08926 Alloy 31/UNS N08031,Alloy 20/N08020 Alloy C-22/Hastelloy C-22/N06022 Alloy 600/Inconel 600/UNS N06600, | |||

| ASTM/ASME SB 473 | Alloy 20/UNS N08020 | |||

| ASTM/ASME SB 574 | Hastelloy C-276/UNS N10276 | |||

| ASTM/ASME SB 637 | Alloy 718/Inconel 718/N07718 | |||

Stainless Steel | ASTM/ASME SA 276 | 304/SUS304/UNS S30400, 304L/UNS S30403, 316/UNS S31600 316Ti/UNS S31635, 316H/UNS S31609 316L/UNS S31603, 310S/UNS S31008 321/UNS S32100, 321H/UNS S32109 347/UNS S34700, 347H/UNS S34709 F51/S31803/2205, F53/S32750/2507 F55/S32760, F44/S31254/254SMO S31050/1.4466 F904L/N08904, | ||

| ASTM/ASME SA 479 | 304H/UNS S30409 | |||

Carbon Steel and Low Alloy Steel | ASTM/ASME SA 694 | F42, F46, F48, F50, F52, F56, F60, F65 F70 | ||

| ASTM/ASME SA 350 | LF2, LF3 | |||

| ASTM A105/ASME SA105 | ||||

Feature:

1.Excellent inoxidability in the high temperature.

2.Good resistance to carbonizing.

3.Good inoxidabilitiy in sulfur atmosphere.

4.Good mechanical property in both room temperature and high temperature.

5.Good resistance to stress corrosion cracking, have high creep rupture strength since it limits the carbon content and

grain size, so recommend to use for above 500ºC environment.

| C | Si | Mn | P | S | Cr | Ni | Co | Fe | W | Mo | Cu | |

| max | 1.30 | 1.80 | 0.50 | 0.030 | 0.030 | 32.00 | 3.00 | bal | 3.00 | 5.50 | 0.50 | 0.50 |

| min | 1.00 | 0.60 | 26.50 | 4.00 | ||||||||

| Cu | ||||||||||||

| Stellite 6 Mechanical property | ||||||||||||

| Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) | Reduction (%) | Hardness (HRC) | Charpy Impact (J) | |||||||

| 541 | 896 | <1 | 40-46HRC | |||||||||

| Heat treatment | ||||||||||||

| Solution treatment :900°C±10°C,hold for 2.5 hours, AC to 300°C or below, cool in air | ||||||||||||

| stellite 6 Raw material: Round bar, rod, castings | ||||||||||||

| valve components: seat rings. | ||||||||||||

Meanwhile,we also could supply COBALT CASTINGS, Cobalt Foundry. SAE UMCo-51. Co50, Co40, Co20, Co-base materials,

cobalt alloy castings, UMCo51,

SAE UMCo-50, 2.4778, G-CoCr28 acc. to EN 10295: 2002,

UMCo50Nb, UMCo-20,

UNS R30075 (ASTM F75, ISO 5832-4) Co-Cr-Mo Alloy,

Conicro 5010 W, Haynes 25,Conicro 5010 W - alloy 25

Conicro 4023 W, Haynes 188, Conicro 4023 W - alloy 188

Cobalt - Chromium, Co-Cr, cobalt casting alloys,

Cobalt - Chromium - Niobium, Co-Cr-Nb, Cobalt-Based Alloy Castings,

Cobalt - Chromium - Tungsten, Co-Cr-W, Alnico alloys, Al-Ni-Co, Alniko,

STELLITE 1, STELLITE 3, STELLITE 4, STELLITE 6, STELLITE 12, STELLITE 20, STELLITE 21, STELLITE 31,

STELLITE 190, STELLITE 238, STELLITE 306, STELLITE 694,

STELLITE F, STELLITE SF1, STELLITE SF6, STELLITE SF12, STELLITE SF20, TRIBALOY T400, TRIBALOY T800

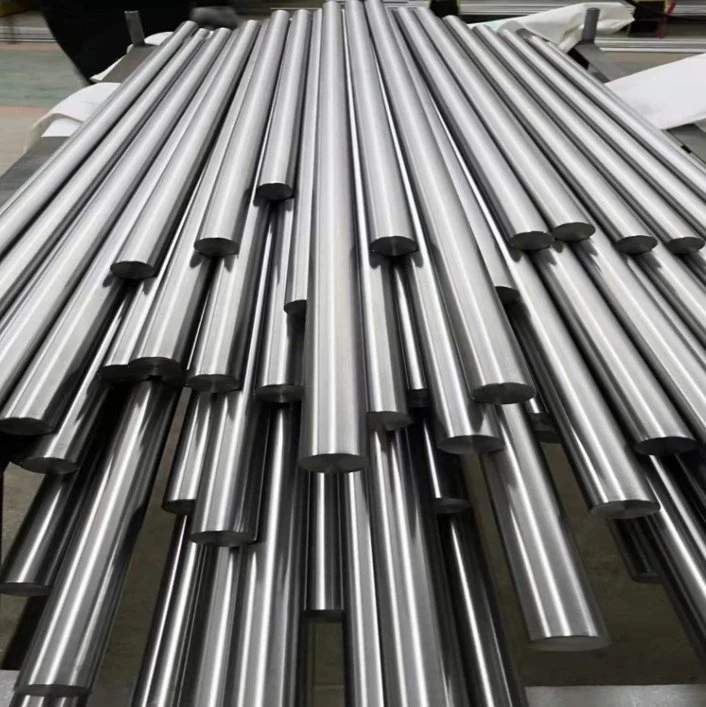

Product show:

About us:

We produce High Temperature Superalloy Round Bars.

We melt good quality Co-based Alloy Round Bars with Vacuum Furnaces and Induction Furnaces.

We can cast and machine the hard Cobalt-based Alloy Round Bars as per the drawings.

We would like to help select suitable Co-based Alloy Grade as per your specific working condition.

Cobalt-based alloys have been in use for producing various components such as vanes or combustion chambers. The material can be implemented as wrought or as precision-cast parts or as centrifugal cast parts. The design of cobalt superalloys, which is aimed at an enhancement of both their oxidation resistance and their hot corrosion resistance, has received considerable impetus recently, especially since the advent of overlay coating techniques and the extensive studies which have been undertaken to elucidate the hot corrosion mechanisms and the effect of alloying elements.

Our warehouse

Our factory:

Our factory:

Product Testing:

Certificate:

Certificate: