Product Description

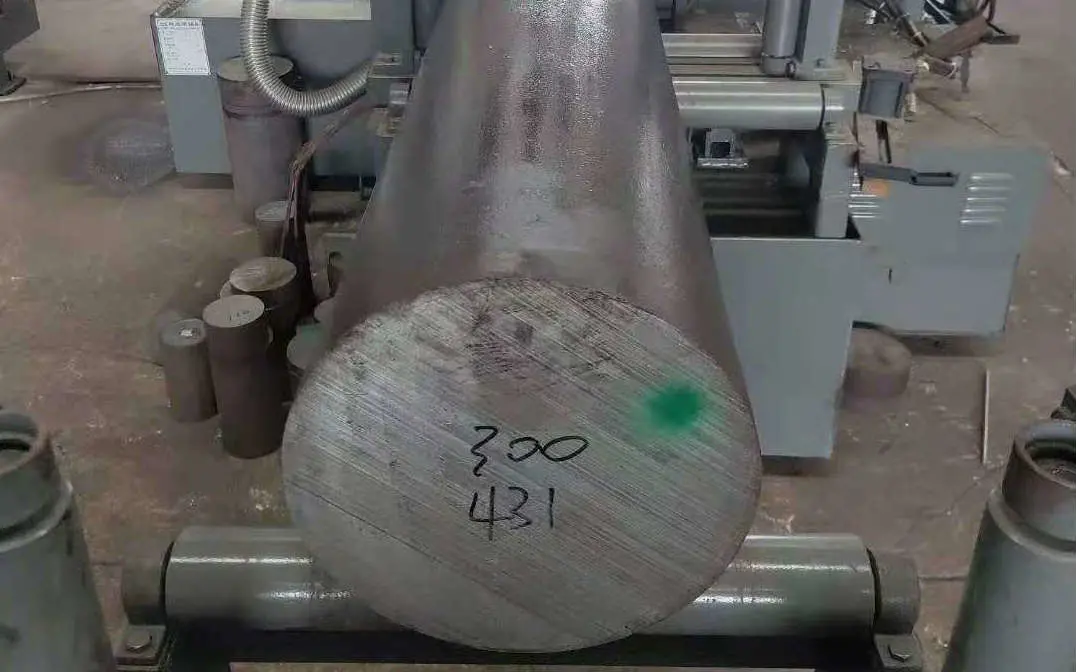

DIN 1.2787, AISI 431 ESR Stainless Steel Round Bars for Glass Moulds

grades AISI 431, DIN 1.4057, 1.2787 for glass mold manufacturing, products delivered in prehardened or soft annealed state.

surface finish: rough peeled.

NEW GENERATION FOR GLASS MOLDS MANUFACTURING

431 mod. a special grade, it's a improved type from 1.4057.

ESR 431 premium supplies longer mold life with its extra fine structure.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | V |

| FG431 | 0.17 ~ 0.22 | 0.4 ~ 0.5 | 0.6 ~ 0.7 | 0.025 max. | 0.015 max. | 15.5 ~ 16.0 | 1.7 ~ 1.9 | 0.2 ~ 0.25 | 0.06 ~ 0.1 |

| DG431 | 0.20 ~ 0.25 | 0.25 ~ 0.35 | 0.8 ~ 0.9 | 0.025 max. | 0.015 max. | 15.5 ~ 16.0 | 1.8 ~ 1.9 | 0.3 ~ 0.35 | 0.05 ~ 0.1 |

| 431 is a high chromium-low nickel high hardenability Martensitic stainless steel with high strength and good corrosion resistance, as generally supplied hardened and tempered in the tensile range 850 - 1000 Mpa (condition T) Brinell range 248 - 302.Characterised by very good corrosion resistance in general atmospheric corrosive environments, good resistance to mild marine and industrial atmospheres, resistant to many organic materials, nitric acid and petroleum products coupled with high tensile and high yield strength plus excellent toughness in the hardened and tempered condition. 431 due to its excellent hardenability is capable of being through hardened up to Rc44, depending upon carbon content and section size. Small sections can be air cooled and larger sections oil quenched for maximum through hardness.Pre hardened and tempered 431 will also respond readily to nitriding achieving a typical surface hardness of over Rc65. The nitriding process however reduces the corrosion resistance and is therefore not generally recommended except for critical applications where the benefit outweighs all other considerations. Used extensively for parts requiring a combination of high tensile strength, good toughness and good corrosion resistant properties. Typical applications are: Aircraft Parts and Components, Bolts and Nuts, Fasteners, Pump Shafts, Propellor Shafts, Studs, Valve Parts etc. Material magnetic in all conditions. |

| Colour Code | Stocked Sizes | |

| Purple (Bar end) | STOCKED SIZES | 6.35 to 260 mm diameter. |

| Bar Finish | ||

| Peeled, Cold Drawn Turned and Polished, and Centreless Ground. | ||

| Related Specifications | |

| Australia | AS 2837-1986 431 |

| Germany | W.Nr 1.4057 X20CrNi17 2 |

| Great Britain | BS970 Part3 1991 431S29 BS970 - 1955 EN57 |

| Japan | JIS G4303 SuS 431 |

| USA | ASTM A276-98b 431 SAE 51431 AISI 431 UNS S43100 |

| Chemical Composition | |||||||||||

| Min. % | Max % | ||||||||||

| Carbon | 0.12 | 0.20 | |||||||||

| Silicon | 0 | 1.00 | |||||||||

| Manganese | 0 | 1.00 | |||||||||

| Nickel | 1.25 | 3.00 | |||||||||

| Chromium | 15.00 | 18.00 | |||||||||

| Phosphorous | 0 | 0.04 | |||||||||

| Sulphur | 0 | 0.03 | |||||||||

| *Carbon range can vary considerably *Nickel addition optional. | |||||||||||

| Mechanical Property Requirements For Material in the Annealed and Heat Treated - Condition T To AS2837 - 1986 431 and BS970 Part3 1991 431S29 | |||||||||||

| Condition | Annealed | *T | |||||||||

| Tensile Strength Mpa | Min | 850 | |||||||||

| Max | 1000 | ||||||||||

| 0.2% Yield Strength Mpa | Min | 635 | |||||||||

| Elongation on 5.65√S0 % | Min | 11 | |||||||||

| Izod Impact Valua J mm | Min | 63 34 63 20 | |||||||||

| Hardness HB | Min | 248 | |||||||||

| Max | 277 | 302 | |||||||||

| *Material stocked generally in condition T. NB. Check the mill certificate if critical for end use. | |||||||||||

| Typical Mechanical Properties At Room Temperature - *Hardened and Tempered to Condition T | |||||||||||

| Tensile Strength Mpa | 940 | ||||||||||

| 0.2% Yield Strength Mpa | 750 | ||||||||||

| Elongation in 50mm % | 19 | ||||||||||

| Impact Izod J | 65 | ||||||||||

| Hardness | HB | 280 | |||||||||

| Rc | 30 | ||||||||||

| *Typical Hardening Temperatures | 980oC - 1020oC | ||||||||||

| *Typical Tempering Temperatures | 640oC - 660oC | ||||||||||

| 590oC - 610oC | |||||||||||

| Typical Mechanical Properties At Room Temperature - Hardened By Oil Quench at 980oC and Tempered as Indicated | |||||||||||

| Tempering Temperature oC | 250 | 370 | 480 | 590 | 650 | ||||||

| Tensile Strengt Mpa | 1370 | 1390 | 1410 | 980 | 920 | ||||||

| 0.2% Yield Strength Mpa | 1030 | 1130 | 1200 | 790 | 690 | ||||||

| Elongation in 50mm % | 16 | 16 | 16 | 19 | 20 | ||||||

| Impact Charpy J | 54 | *34 | *16 | 65 | 70 | ||||||

| Hardness | HB | 410 | 420 | 425 | 295 | 270 | |||||

| Rc | 44 | 45 | 46 | 32 | 29 | ||||||

| High tensile strength and high yield strength with slightly lower impact properties when tempered below 370oC. Section Size 30mm *Note drop in impact properties.Tempering within the range 370oC - 565oC should be avoided. | |||||||||||

| Elevated Temperature Properties | |||||||||||

| 431 displays good resistance to scaling in continuous service up to 700oC. Its use however at these higher working temperatures results in a substantial drop in tensile strength and hardness, with subsequent increase in ductility. | |||||||||||

| Typical Mechanical Properties at Elevated Temperatures, Hardened at 1010oC and Tempered at 30oC Above Working Temperature | |||||||||||

| Tempering Temperature oC | 510 | 570 | 620 | ||||||||

| Working Temperature oC | 480 | 540 | 590 | ||||||||

| Tensile Strengt Mpa | 1350 | 720 | 435 | ||||||||

| Elongation in 50mm % | 15 | 20 | 26 | ||||||||

| Room Temperature Hardness after Test | HB | 440 | 330 | 280 | |||||||

| Rc | 47 | 37 | 30 | ||||||||

| NB. Creep and stress rupture strength is also substantially reduced at these higher working temperatures. | |||||||||||

| Low Temperature Properties | |||||||||||

| 431 is not recommended for use at sub-zero temperatures due to a substantial drop in impact properties consistent with most steels other than the austenitic steel types. | |||||||||||

| Cold Bending | |||||||||||

| In the hardened and tempered as supplied condition will be extremely difficult due to the high yield strength and is not generally recommended. | |||||||||||

| Hot Bending | |||||||||||

| In the hardened and tempered as supplied condition it is not recommended due to its affect on the mechanical properties within the heat affected zone. | |||||||||||

| Corrosion Resistance | |||||||||||

| 431 has the highest corrosion resistance of all the Martensitic stainless steels, and while not as high as the austenitic stainless steels it is in certain corrosive environments similar to that of 301 and 302 grades.NB. It has optimum corrosion resistance in all environments in the hardened and tempered condition, and is not therefore recommended for use in the annealed condition. It is most important that oxygen is always allowed to circulate freely on all stainless steel surfaces to ensure that a chrome oxide film is always present to protect it. If this is not the case, rusting will occur as with other types of non stainless steels.For optimum corrosion resistance surfaces must be free of scale and foreign particles. Finished parts should be passivated. | |||||||||||