Product Description

Ready stock of steel bar:more than 1000tons

Delivery time:7-10days

Alloy Steel Round Bar 4140/Aisi 4140 Round Bar,1.7225 Steel,4140 Round Steel Bar

1.4140 42CrMo SCM440 steel rod Chemical Composition (%):

2.4140 alloy steel bar avaliable sizes

4.42CrMo4 steel bar delivery condition:

Hot rolled or forged, Peeled or black surface, annealed or QT.

4.4140 SCM440 steel bar applications:

Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears.

5.1.7225 42CrMo4 steel round bar heat treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

8. 4140 steel bar delivery time:

always ready stock shipped within 7days,30 days for new material

9. 42CrMo4 alloy steel bar production process:

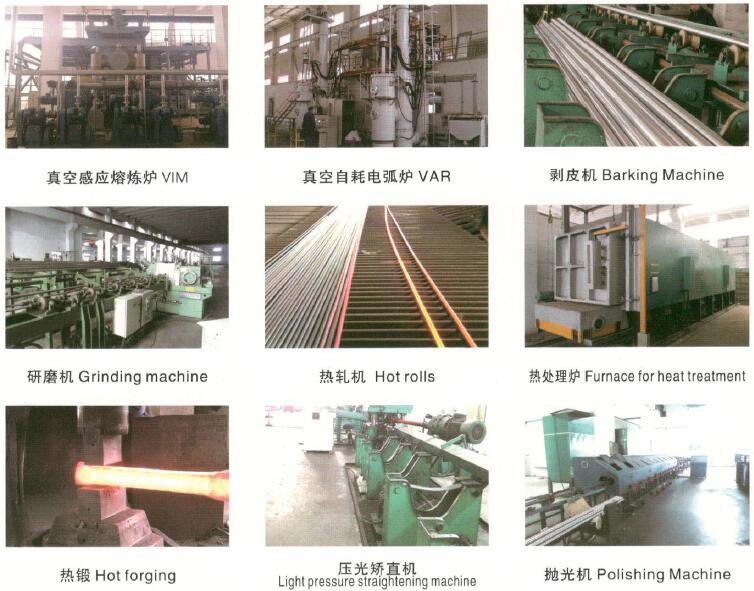

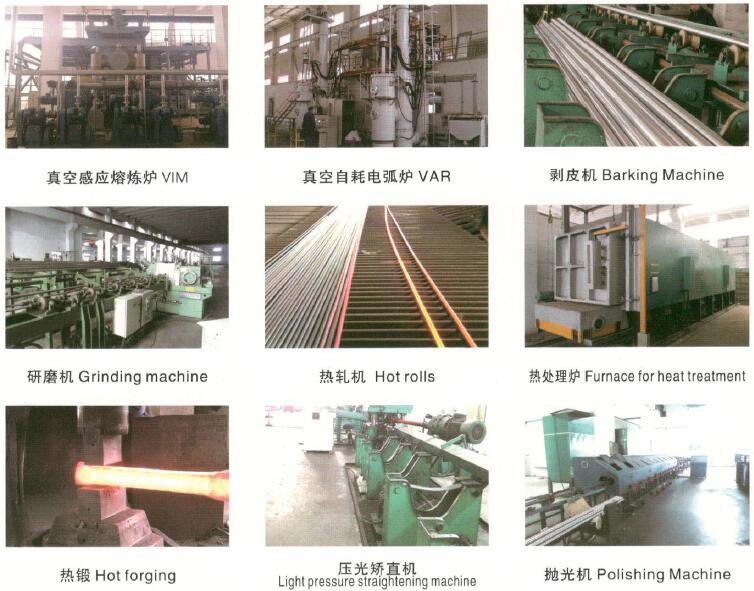

EAF+LF+VD ( necessary) +UT+ Peeled(optional) +Turned (optional) + Heat Treatment (optional)

Delivery time:7-10days

Alloy Steel Round Bar 4140/Aisi 4140 Round Bar,1.7225 Steel,4140 Round Steel Bar

1.4140 42CrMo SCM440 steel rod Chemical Composition (%):

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo4 | 0.38-0.45 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 | 0.90-1.20 | 0.15-0.25 |

| 1.7225 | 0.38-0.45 | ≤0.40 | 0.60-0.90 | ≤0.025 | ≤0.035 | 0.90-1.20 | 0.15-0.30 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| Commodity delivery condition | Dimensions |

| Hot rolled steel round bars | 10mm to 350mm |

| Forged steel round bars | 200mm to 800mm |

| Forged steel square block | 200mm*200mm to 500mm*500mm |

| Forged steel flat block | (150mm to 500mm)*(200mm to 500mm) |

| Hot rolled and peeled or turned steel bright bars | 20mm to 800mm |

4.42CrMo4 steel bar delivery condition:

Hot rolled or forged, Peeled or black surface, annealed or QT.

4.4140 SCM440 steel bar applications:

Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears.

5.1.7225 42CrMo4 steel round bar heat treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

6SCM400 4140 steel bar inspection:

Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,Ultrasonic according to the test standards:SEP1921-84,GR.3 CLASS C/C 7 Steel bar packing situation:

standard seaworthy packing or as customer required8. 4140 steel bar delivery time:

always ready stock shipped within 7days,30 days for new material

9. 42CrMo4 alloy steel bar production process:

EAF+LF+VD ( necessary) +UT+ Peeled(optional) +Turned (optional) + Heat Treatment (optional)

Our service

With dynamic and passionate professional sales team and technical team,Our company Dajin make great efforts to integrate China's steel resources and dedication to customers the provision of specialized steel products and services.Hope establish a good relationship with clients, growth together.