Product Description

S45C Forged Round Bar / S45C Forged Rough Turned Steel Round Bar / S45C Forged Steel Square Bar

1.About 1045Carbon Steel :

AISI 1045 steel is a medium tensile steel supplied in the black hot rolled or normalized condition.

It has a tensile strength of 570 - 700 MPa and Brinell hardness ranging between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot rolled / forged condition.

5.Inspecting:

UT according toSEP1921 C/c, D/d, E/e, A388 or GB/T 6402,

Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,

6.Delivery Condition:

Forged+black surface

Forged+rough machined

Forged+rough turned+QT/annealed/normalized

Surface condition: Black; Peeled; Polished; Machined; Grinded; Turned; Milled

7.Manufacture:EAF+LF+VD(Annealed,normalized,Quenched+Tempered,peeled,rough turned).

8.Heat Treatment: Normalized / Annealed / Quenched / tempered (optional)

Main Grade we can supply for forged steel bars

1.About 1045Carbon Steel :

AISI 1045 steel is a medium tensile steel supplied in the black hot rolled or normalized condition.

It has a tensile strength of 570 - 700 MPa and Brinell hardness ranging between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot rolled / forged condition.

2. AISI 1045 Steel Specification and Relevant Standards

| GB | 45# |

| ASTM | 1045 |

| JIS | S45C |

| DIN | C45 |

| BS | IC45 08047 |

| NF | C45 |

3. ASTM 1045 Steels And Equilvalents Chemical Composition

| Standard | Grade | C | Si | Mn | P | S |

| GB/T699 | 45 | 0.42-0.5 | 0.17-0.37 | 0.5-0.8 | 0.035 | 0.035 |

| JIS G4051 | S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | 0.03 | 0.035 |

| ASTM A29/A29M | 1045 | 0.43-0.5 | 0.15-0.35 | 0.6-0.9 | 0.04 | 0.05 |

| EN 10083-2 | C45E/1.1191 | 0.43-0.5 | 0.4 | 0.5-0.8 | 0.03 | 0.035 |

4.AISI 1045 Forged Round Bar Mechanical Property :

(For refference only, property can be changed by adjusting quenching and tempereing tempreture)

| Tensile Strength(Mpa) | 600 (min) |

| Yield Strength(Mpa) | 355 (min) |

| Elongation | 16 (min) |

| Shrinkage | 40 (min) |

| Akv(J) | 39 (min) |

5.Forged Steel Size we can supply:

| Forged Steel Round Bar | Φ85mm~1200mm |

| Forged Square steel Bar: | 150×150-800×800mm |

| Forged Flat Blocks: | (150mm-800mm)*(200mm-800mm) |

| Forged Shaft and Forged Ring | According to Customer's drawing |

5.Inspecting:

UT according toSEP1921 C/c, D/d, E/e, A388 or GB/T 6402,

Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,

6.Delivery Condition:

Forged+black surface

Forged+rough machined

Forged+rough turned+QT/annealed/normalized

Surface condition: Black; Peeled; Polished; Machined; Grinded; Turned; Milled

7.Manufacture:EAF+LF+VD(Annealed,normalized,Quenched+Tempered,peeled,rough turned).

8.Heat Treatment: Normalized / Annealed / Quenched / tempered (optional)

Main Grade we can supply for forged steel bars

| Steel series | Representative steel type |

| Carbon Steel series | AISI 1020,1045,A36,S355JR,S355JO |

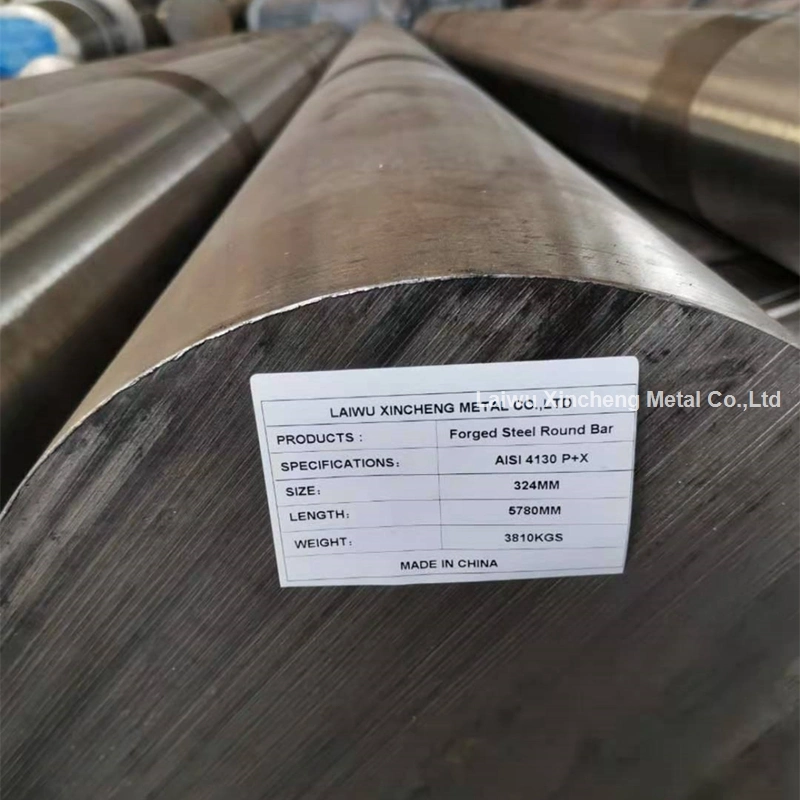

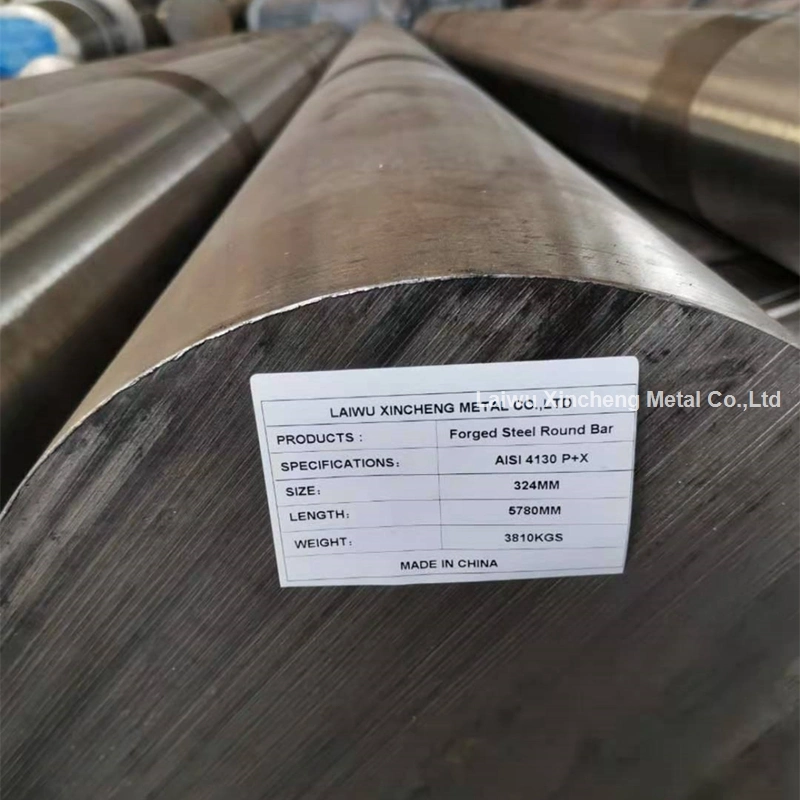

| Petroleum machinery series | AISI4150,AISI4140,AISI4130, |

| 30CrMo,4145H | |

| Tool mold series | 1.2714,5CrMnMo,5CrNiMoV, |

| 1.2738,1.2311,1.2312 1.2714 H13 | |

| Bearing series | 52100,GCr15,SUJ2 |

| Marine series | 4140,42CrMo,SCM440, |

| 709M40 | |

| Car series | SAE8620,20CrNiMo, |

| SNCM220 | |

| Heavy-duty transmission series | 40CrNiMo,SNCM439, |

| SAE4340,EN24 | |

| Mining machinery series | 655M13,826M40, |

| 25CrMo | |

| Wind power gear series | 18CrNiMo7-6, 17CrNiMo6, 1.6582,1.6587,SAE8620 |

| Wind power spindle series | 34CrNiMo6,817M40 |

| Nitriding series | 20MnCr5,38CrMoAl, |

| 31CrMoV9 | |

| Pressure vessel series | 15CrMo,13CrMo4-4 |

| Metallurgical roll series | 21CrMoV511,W1.7225, |

| EN19,709M40 |

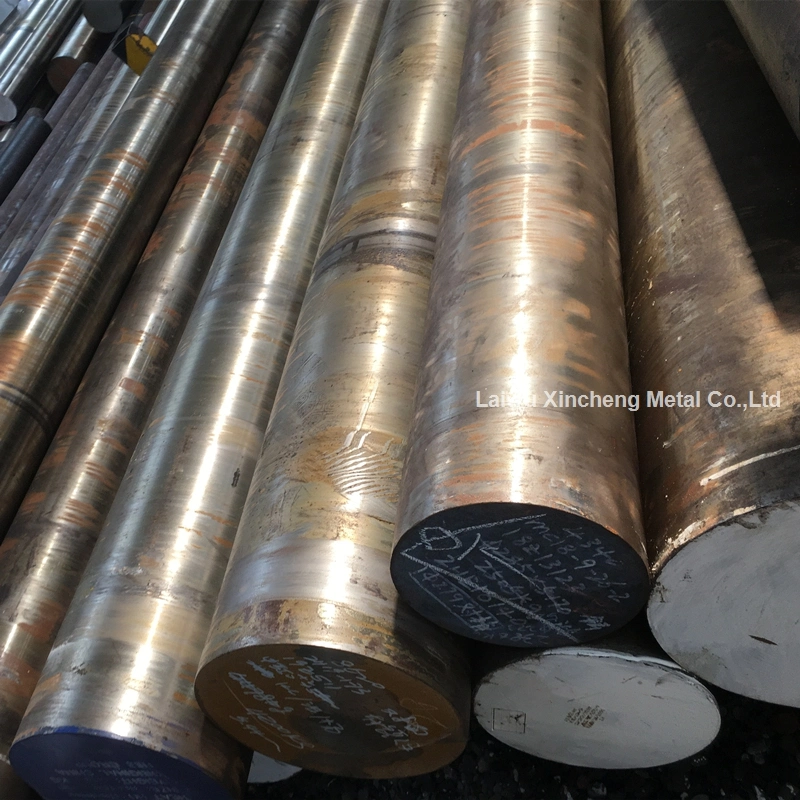

About our factory:

Our main products include Forged Steel Round Bar from Sizes 85mm to 1100mm, Forged Steel Square Bar from Sizes 150×150 to 800×800mm with various grade ;The largest production steel ingot 15T, mainly forged alloy steel, carbon steel and other materials. The annual output of forged round can reach 60,000 tons. The products are widely used and can be supplied to users in metallurgy, chemical, hydraulic, port and marine machinery The main equipment includes a 2000-ton hydraulic press, a 3-ton electro-hydraulic hammer, a 2.5-meter ring rolling machine, and is equipped with large and small traveling machines, metalworking lathes, and multiple large and small sawing machines. The company now has more than 100 sets of production equipment from a whole set of processes from blanking, heating, forging to heat treatment and machining.