Basic Info.

Model NO.

CXHB-2

Special Use

Free Cutting Steel

Manufacture Method

Hot Rolled, Forged, Cold Drawn

Steel Grade

Carbon Steel and Alloy Steel

MOQ

1 Ton

Transport Package

Seaworthy Export Packing

Specification

80mm-325mm

Trademark

OEM, Chengxin

Origin

Jiangsu, China

HS Code

73049000

Production Capacity

24000 Tons/Year

Product Description

PART I: PRODUCT INTRODUCTION

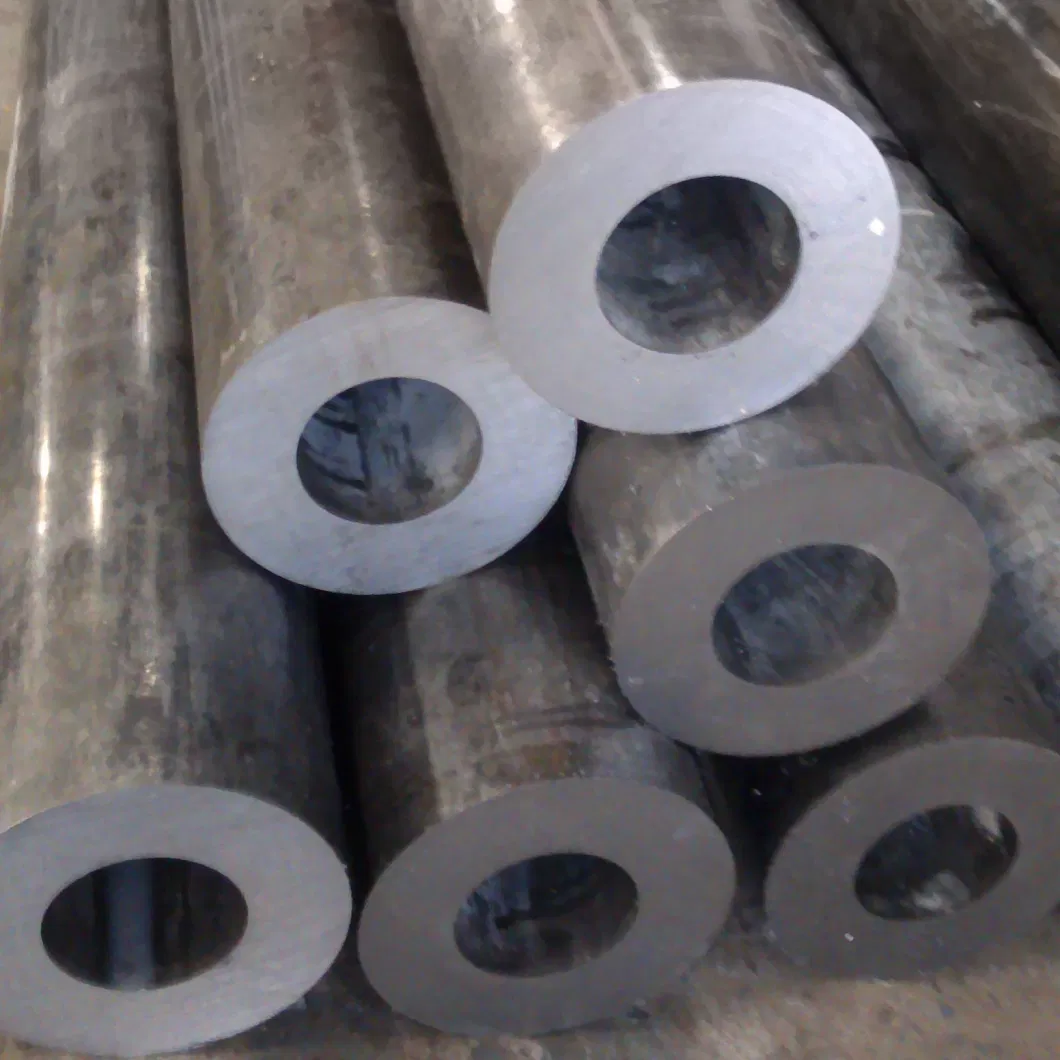

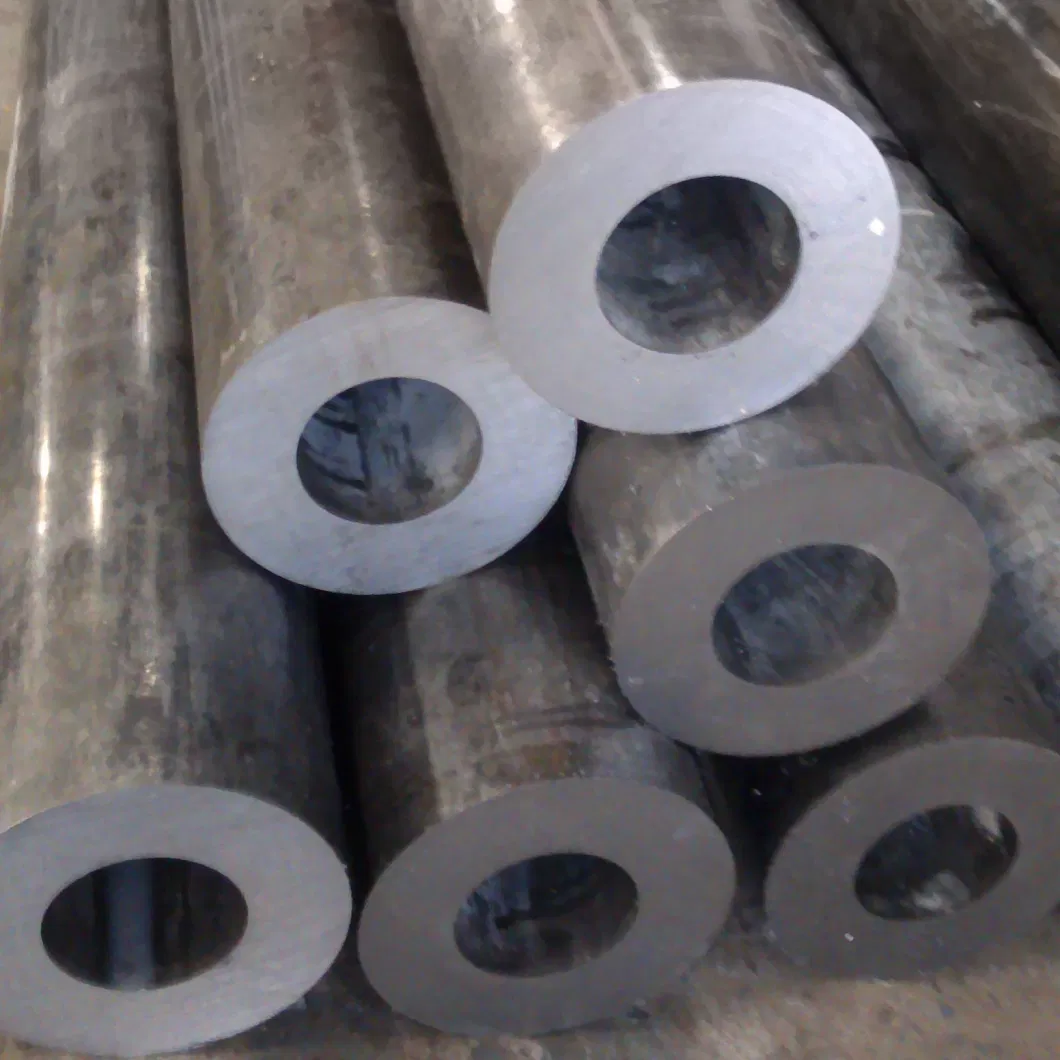

1. Description: Hollow bar is a kind of thick wall seamless tube or pipe. In Chengxin, we can supply cold drawn hollor bars, hot rolled+deep hole bored hollow bars, and hot rolled or forged+deep hole drilled hollow bars for our customers, and machining&turning service as per drawing is available.

2. Commodity: SAE4130 alloy steel hollow bar

3. Available steel gardes:

5. Size range:

6. Manufacture method: Hydraulic cold drawn, hot rolled+deep hole boring, hot rolled+deep hole drilling

7. Delivery Condition:

8. Turning&machining: as per drawing

9. Standard export packing: sea-worthy export packing.

10. Customized packing or marking are available upon request.

DEEP HOLE BORED HOLLOW BAR:

MACHINED&TURNED HOLLOW BAR:

COLD DRAWN HOLLOW BAR:

PART II: FREQUENTLY ASKED QUESTIONS

1. MOQ: 5 tons/size depending on the size.

2. Delivery Time: 30-45 days average.

3. Warranty&Guarantee: Warranty&guarantee period is 6 months since we deliver the tubes, and we are not responsible for quality problem caused by wrong unloading or storage after shipment. We welcome customer's inspection before shipment.

4. Payment Method: We accept payment method like T/T, L/C, or D/P, but it depends on our investigation about customers. We have a solution to evaluate the credit of customers from all over the world, and time and amount of D/P we can release is determined by the evaluation.

5. Quality Control: We purchase raw material from stable suppliers who are leading steel mills, and we inspect the raw material as per the specifications. During our production procedure, there is inspection and quality control in every stage.

PART III: COMPANY INTRODUCTION

We are a manufacturer of cold drawn, cold rolled, and hydraulic cold drawn steel tubes with OD upto 356mm since 2002. Covering an area of about 32000M2, we have 12 standard workshops with 2 hydraulic cold drawing benches, 4 chain cold drawing benches, and 2 ERW mills. Our facilities covers all the production procedures from pickling, cold drawing,heat treating,saw cutting, straightening,inspection,packing to further machining &turning, cold drawing die fabrication, and equipment repairation&maintenance.

FACTORY APPEARANCE:

HYDRAULIC COLD DRAWING BENCH:

DEEP HOLE BORING/DRILLING MACHINE:

LATHES:

SKIVING&ROLLER BURNISHING:

HONING:

1. Description: Hollow bar is a kind of thick wall seamless tube or pipe. In Chengxin, we can supply cold drawn hollor bars, hot rolled+deep hole bored hollow bars, and hot rolled or forged+deep hole drilled hollow bars for our customers, and machining&turning service as per drawing is available.

2. Commodity: SAE4130 alloy steel hollow bar

3. Available steel gardes:

| ASTM A519: | SAE1020,SAE1026,SAE1045,SAE1518,SAE1524,SAE1541, SAE4130,SAE4140,SAE4145,SAE4340,SAE8620 |

| DIN 2391-2: | ST45,ST52 |

| EN 10305-1: | E235,E355,C35E,C45E,25CrMo4,34CrMo4,42CrMo4, |

| OD: | 80mm- 325mm |

| W.T: | not limited |

| Length: | 2200mm max |

7. Delivery Condition:

| BKW | BKS | GBK | NBK | Q+T |

| +LC | +SR | +A | +N | |

| Cold drawn | Stress relieved | Annealed | Normalized | Quenched+tempered |

9. Standard export packing: sea-worthy export packing.

10. Customized packing or marking are available upon request.

DEEP HOLE BORED HOLLOW BAR:

MACHINED&TURNED HOLLOW BAR:

COLD DRAWN HOLLOW BAR:

PART II: FREQUENTLY ASKED QUESTIONS

1. MOQ: 5 tons/size depending on the size.

2. Delivery Time: 30-45 days average.

3. Warranty&Guarantee: Warranty&guarantee period is 6 months since we deliver the tubes, and we are not responsible for quality problem caused by wrong unloading or storage after shipment. We welcome customer's inspection before shipment.

4. Payment Method: We accept payment method like T/T, L/C, or D/P, but it depends on our investigation about customers. We have a solution to evaluate the credit of customers from all over the world, and time and amount of D/P we can release is determined by the evaluation.

5. Quality Control: We purchase raw material from stable suppliers who are leading steel mills, and we inspect the raw material as per the specifications. During our production procedure, there is inspection and quality control in every stage.

PART III: COMPANY INTRODUCTION

We are a manufacturer of cold drawn, cold rolled, and hydraulic cold drawn steel tubes with OD upto 356mm since 2002. Covering an area of about 32000M2, we have 12 standard workshops with 2 hydraulic cold drawing benches, 4 chain cold drawing benches, and 2 ERW mills. Our facilities covers all the production procedures from pickling, cold drawing,heat treating,saw cutting, straightening,inspection,packing to further machining &turning, cold drawing die fabrication, and equipment repairation&maintenance.

FACTORY APPEARANCE:

HYDRAULIC COLD DRAWING BENCH:

DEEP HOLE BORING/DRILLING MACHINE:

LATHES:

SKIVING&ROLLER BURNISHING:

HONING: