Product Description

Professional manufacturer of honed tube & chrome rod/bar/shaft, founded in 2004, one of biggest manufacturer in China.

We make honed tubes, Honed steel tubing, Hydraulic cylinder tubes, Skived tubes, Bored tubes; Chrome plated piston rods, Chrome bars, Linear shaft, Hollow rods; Cold drawn tubes, Pre-hone tubes, Ready to hone tubes.

Honed tube is produced using our "Suitable to Hone" Drawn Over Mandrel (DOM) and Cold Drawn Seamless (CDS).

The honing process involves using abrasive polishing stones and abrasive paper to remove small amounts of material, to produce extremely precise ID dimensions and improved finishes.

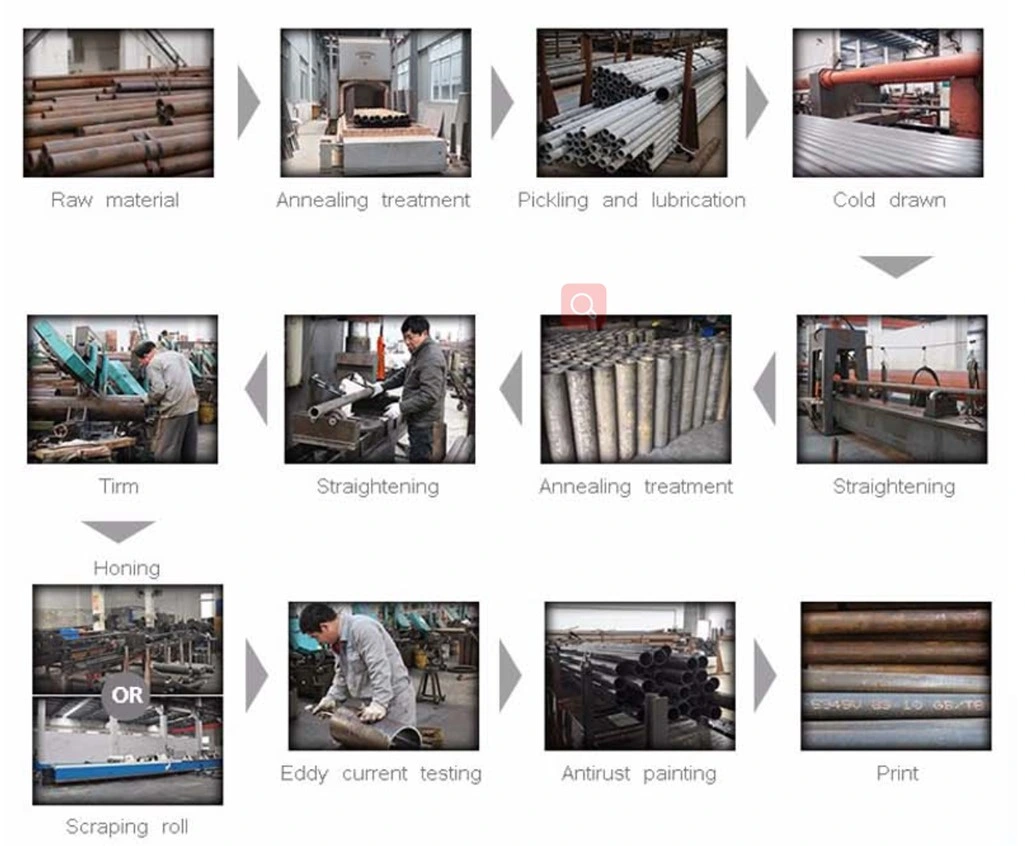

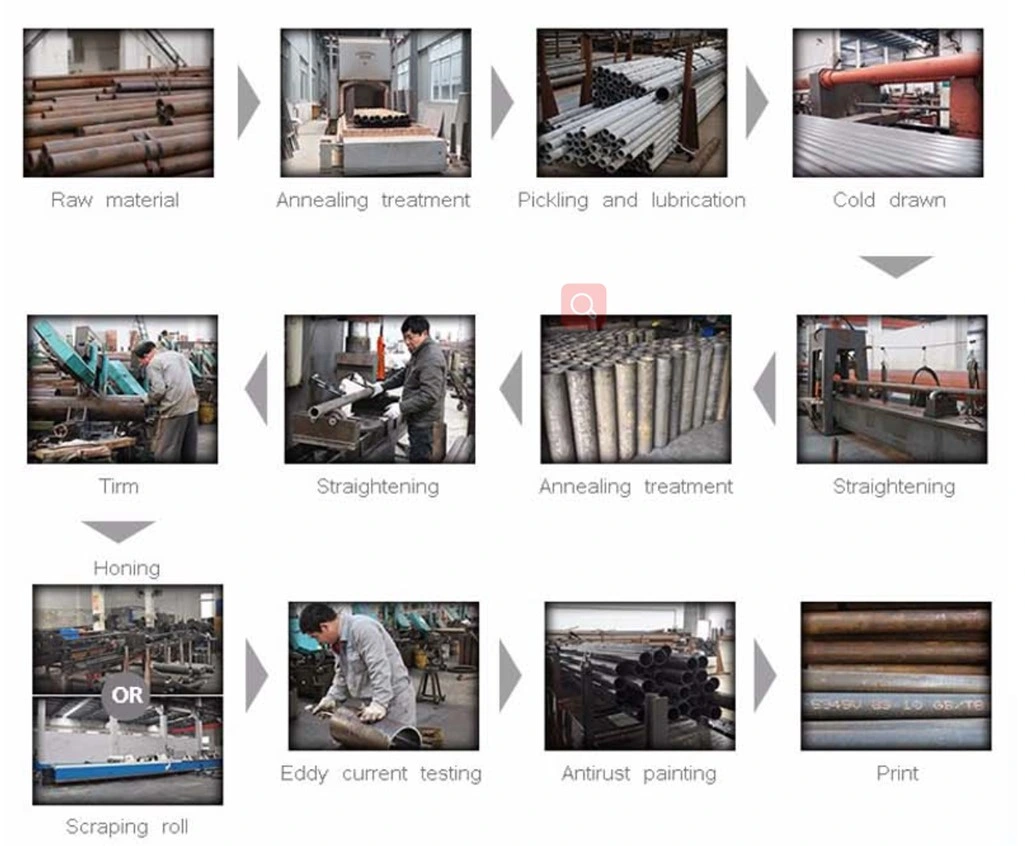

2,Production Processes

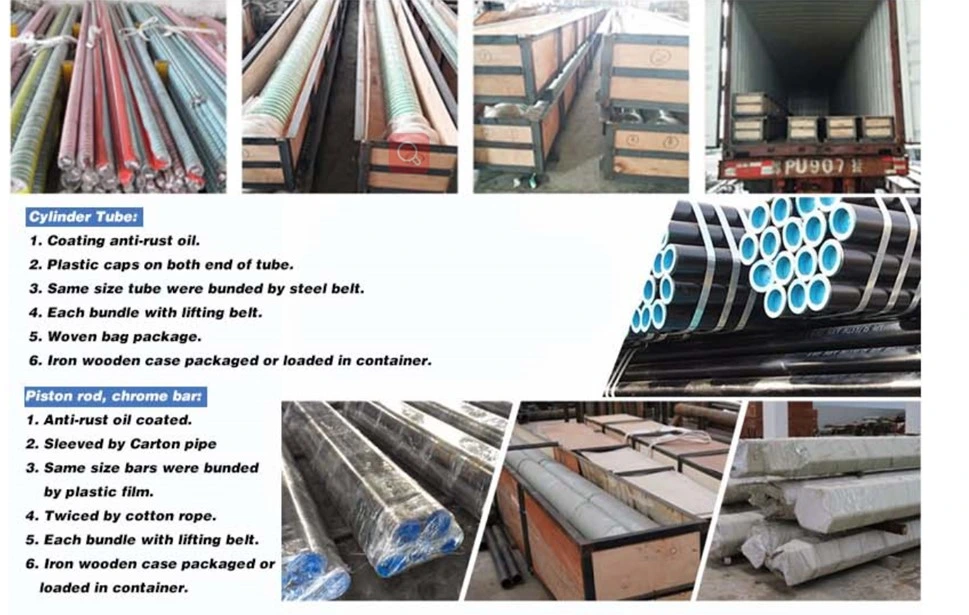

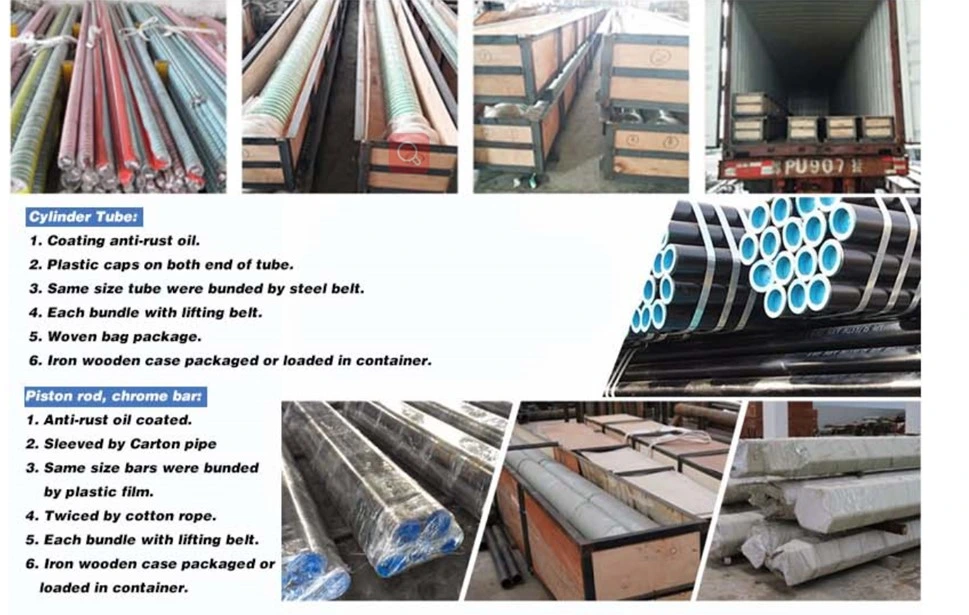

3,Packing

4,Company Show

Factory was established under modern management system and technologies in 2003. It covers an area of 40,000 sq. meters, plant cover 25,000 sq. meters and building area of 30,000 sq. meters. All processing control include cold-drawn, heat treatment, honing, peeling, grinding, polishing. There are 60sets of advanced equipment and 70+ skilled technical workers, annual output over 20,000tons.

5,Why Choice Us

1.Professional, rich experience, reliable.

2.One-stop collection for honed tube, chrome rod, casting cylinder components.

3.Full range of size and material, ready stock goods with fast delivery

4.Customizable, non-standard sizes available

5.Small quantity acceptable

6.Refund or replace if any quality issue.

6,FAQ

Q: Delivery time?

A: Usually could be delivery in 30 days, urgent order could be delivery in 15days.

Q: What 's your main market?

A: We mainly export to Middle East, South Africa and South Eastern Asia. And these two years our products enter to South America too.

Q: Are you a factory?

A: Yes, we are.

Q: Guarantee period?

A: One-year after manufactured, reject items will be resupply or refund.

We make honed tubes, Honed steel tubing, Hydraulic cylinder tubes, Skived tubes, Bored tubes; Chrome plated piston rods, Chrome bars, Linear shaft, Hollow rods; Cold drawn tubes, Pre-hone tubes, Ready to hone tubes.

1,Product Description

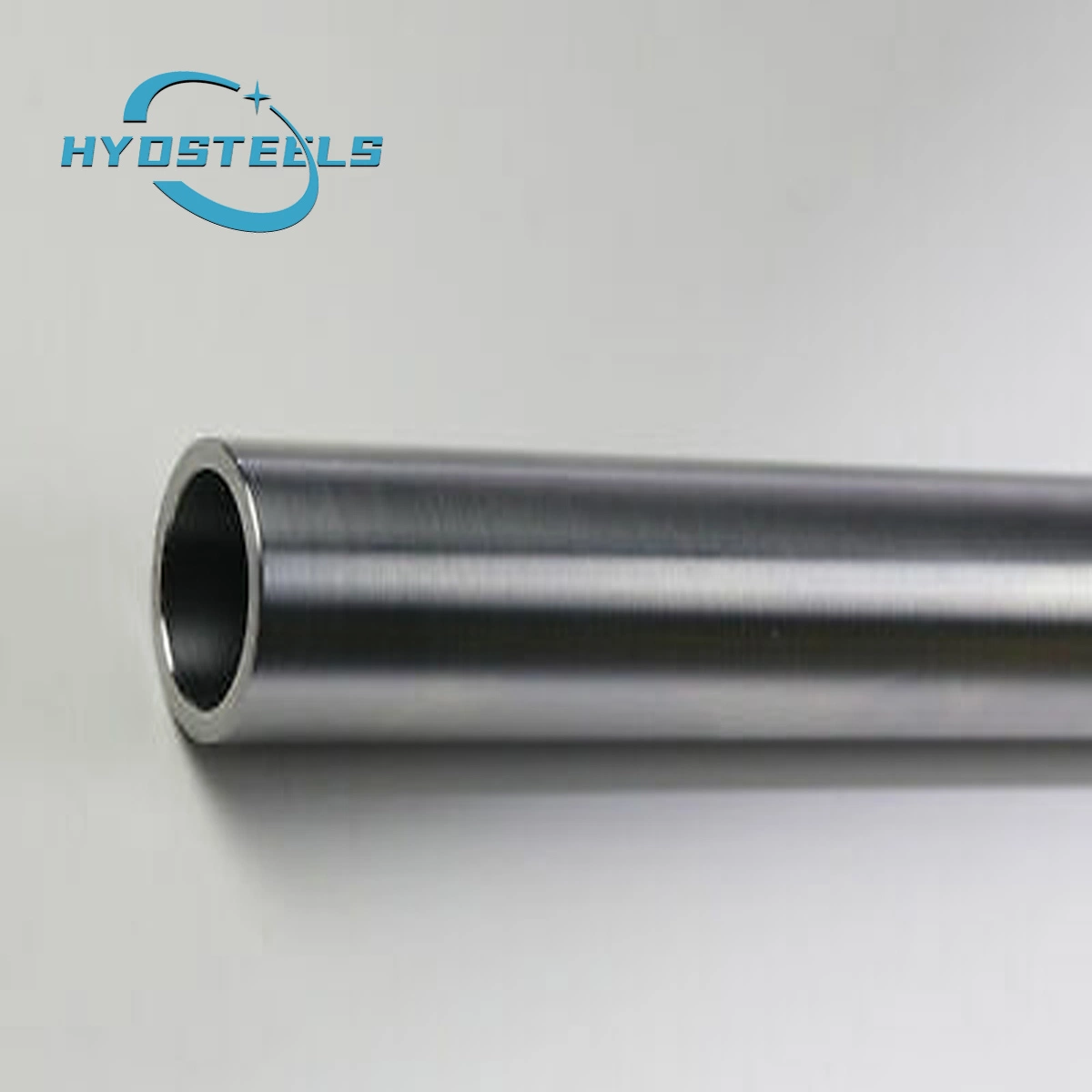

Honed tube is produced using our "Suitable to Hone" Drawn Over Mandrel (DOM) and Cold Drawn Seamless (CDS).

The honing process involves using abrasive polishing stones and abrasive paper to remove small amounts of material, to produce extremely precise ID dimensions and improved finishes.

| Item | Honed Tube |

| Raw material | DIN ST52, SAE1020 |

| Pressure & Temperature Classification | High pressure & temperature piping |

| Inner Diameter | 40mm-320mm |

| Outer Diameter | 50-400mm |

| Thickness | 5-40mm |

| Length | 7000mm |

| Straightness | Max 0.5/1000mm |

| Inside Surface Roughness (Ra) | 0.2-0.4um |

| Tolerance INT | DIN2391 H8 |

2,Production Processes

3,Packing

4,Company Show

Factory was established under modern management system and technologies in 2003. It covers an area of 40,000 sq. meters, plant cover 25,000 sq. meters and building area of 30,000 sq. meters. All processing control include cold-drawn, heat treatment, honing, peeling, grinding, polishing. There are 60sets of advanced equipment and 70+ skilled technical workers, annual output over 20,000tons.

5,Why Choice Us

1.Professional, rich experience, reliable.

2.One-stop collection for honed tube, chrome rod, casting cylinder components.

3.Full range of size and material, ready stock goods with fast delivery

4.Customizable, non-standard sizes available

5.Small quantity acceptable

6.Refund or replace if any quality issue.

6,FAQ

Q: Delivery time?

A: Usually could be delivery in 30 days, urgent order could be delivery in 15days.

Q: What 's your main market?

A: We mainly export to Middle East, South Africa and South Eastern Asia. And these two years our products enter to South America too.

Q: Are you a factory?

A: Yes, we are.

Q: Guarantee period?

A: One-year after manufactured, reject items will be resupply or refund.