Product Description

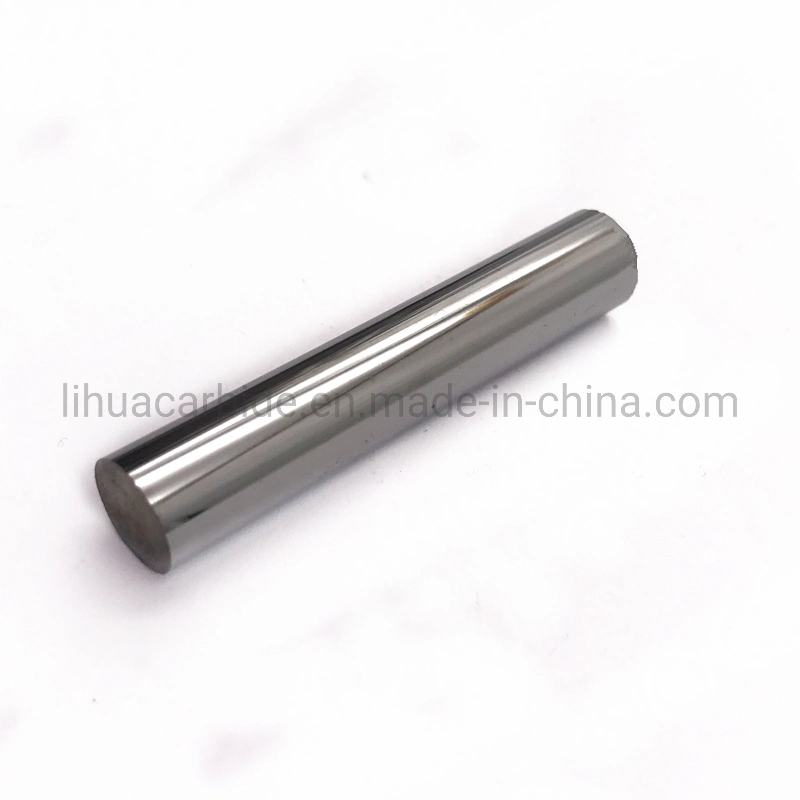

Description of carbide rods

Tungsten carbide rods are mostly applied for drill bits, end mills, and reamers with sub-micron grain grade YG10X, for non-ferrous precision cutting and wood cutting with grade YG6X, and for fiberglass reinforced plastics, titanium alloys, hardened steel with ultra-fine grain grade YG8X, etc. Our Carbide rods have a good shock resistance and bending resistance in use.

| Grade | ISO Code | Cobalt Content (%) | Density (g/cm3) | Hardness (HRA) | TRS (N/Mm2) |

| YG8 | K30 | 8 | 14.80 | 89.5 | 2200 |

| YG6 | K20 | 6 | 14.95 | 90.5 | 1900 |

| YG6X | K10 | 6 | 14.95 | 91.5 | 1800 |

| YL10.2 | K30 | 10 | 14.50 | 91.8 | 2400 |

| YG13X | K30-K40 | 13 | 14.30 | 89.5 | 2600 |

| YG15 | K40 | 15 | 14.00 | 87.5 | 2800 |

Applications:

- It is suitable for the production of various types electrical machine & electronic progressive dies and punches. And carbide rods for end mills. Sintered polished tungsten carbide rod, quality products k10 k20 tungsten carbide rods blanks, solid tungsten carbide rods.

- It is widely used in ceramics, printing machine, plastic, rubber, leather industry and cutting machines, CNC machine, CNC, PCB micro drill bits, etc.

- Cemented carbide is a hard material used in machining tough materials such as carbon steel.

- Most of the time, carbide will leave a better finish on the part, and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools.

| Product Name | YL10.2 Carbide Round Rods for Making Endmill Drills |

| OD tolerance | 0.5 um |

| Surface fineness | Ra 0.025a |

| sizes | Diameter: φ0.5- φ35mm,Length:100-330mm(diameter is φ 1.0- φ 6.0mm, length can up to 700mm) |

| Type | Round(solid, hollow) |

| Grade | YL10.2, YL50, YU06A, YU06R, YF06, YH6F, YG11 etc. |

| Material | Carbide, tungsten carbide, cemented carbide |

| Physical performance | High hardness, strength, wear resistant |

| Application | 1. It is suitable for the production of various types electrical machine & electronic progressive dies and punches. 2. It is widely used in ceramics, printing machine, plastic, rubber, leather industry and cutting machines. |

| Non-standard or Tolerance | Can be customized |

1)Solid tungsten carbide rod/bar/stick

| Diameter(D) | Tolerance | Standard length |

| Φ0.5~5.5 | +0.30~+0.45 | 330 (+5.0/0) |

| Φ6.0~40.0 | +0.20~+0.60 | 330 (+5.0/0) |

2)Hollow tungsten carbide rod/bar/stick

| Outer Diameter | Tolerance of Outer Diameter | Diameter of Hole | Tolerance of Hole | Standard Length |

| Φ2.5~8.0 | +0.2~+0.5 | 0.3~1.5 | +/-0.15 | 330 (+5.0/0) |

| Φ10.0~30.0 | +0.3~+0.8 | 2.0~5.0 | +/-0.30 | 330 (+5.0/0) |

Our Advantages:

1) Business Type: Manufacturer, Factory.

ISO9001:2008, SGS.

2) Advanced technology, HIP sintering and precision grinding to ensure the goods performance;

3) 100% Virgin pure Raw materials;

4) Each product through the strict inspections and confirm to the requirements of the lab parameters;

5) OEM & ODM are welcomed;

6) Small order is acceptable;

7) Flexible payment terms (L/C,T/T, western union, etc);

8) Provide custom made service with customer's drawing; Other size could be offered by your requirements;

9) We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items all available;

10) Fast delivery and high quality;

11) Best after-sale service.

Tungsten Carbide Ground Bar Grade Information

| Grade | Density(g/cm3) | T.R.S MPa | Hardness HRA | Performance & Application recommended |

| YL10.2 | 14.50 | 3400 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

| YG11C | 14.40 | 2260 | 87.5 | Qualified for molding the drills for heavy-duty rock drill:detachable bits used for deep hole drilling,rock drill torlley etc. |

| YG6X | 14.90 | 1560 | 91.0 | Qualified for machiningof chilled cast iron,alloy cast iron,refractory steel ana alloy steel.Also qualified for the machining of common cast iron. |

| YS2T | 14.45 | 2800 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

| YG15 | 14.10 | 2400 | 86.5 | Used for punch dies,stamping dies and wear resistance parts. |

Our service

1.According to your drawings paper supply product for you ;

2.Professional suggestion of product;

3.Could accept all payment terms of T/T,western union ,Paypal;

4.Professional technical for you service the product.

5.Delivery:within 25-30 days upon confirm the prepaid.

Main Products

Our Company

1. First packed in plastic boxes sperately

2. Then in paper box, the type can be seen from the special designed part

3. Last in cartons for final shipment

Shipping Methods

By air or sea,DHL,UPS,FEDEX,TNT or as your resquest.

Below shows the estimate delivery time for different courier:

DHL: 10-14 working days

FedEx: 7 to 10 working days

UPS: 7 to 10 working days

EMS: 10-14 working days

Contact

Foreign Sales Representative: Lumina

Website: http://lihuacarbide.en.made-in-china.com

Factory Address: B-11 Gaoke E-commerce Industrial Park, Xinma South Road, Tianyuan zone, Zhuzhou city 412000, Hunan province, China