Product Description

| Name | stainless steel pipe |

| Standard | ASTM, GB, JIS, DIN, EN, AISI |

| Material Grade | TP304 TP304L TP316 TP316L TP347 TP347H TP321 TP321H TP310 TP310S |

| TP410 TP410S TP403 | |

| S31803/S32205 S32750 S32760 | |

| Outer Diameter | Seamless Pipe: 4mm-812.80mm |

| Welded Pipe: single slit(Φ8mm-Φ630mm); girth(Φ630mm-Φ3000mm), | |

| Thickness | Seamless Pipe: 0.5mm - 60mm |

| Welded Pipe: single slit(0.5mm-25mm);girth(3mm-45mm) | |

| Length | 5.8-6.1 m or as customers' request |

| Tolerance | Acording to the Standard. |

| Surface | 180G, 320G, 400G Satin / Hairline |

| 400G, 500G, 600G or 800G Mirror finish | |

| Test | UT, ET, HT, RT,ect, and others according to the standard,or as the requests of the customers |

| Certificate | ISO9001-2008,ASME, PED |

| Delivery Time | 7-30 Days, Depends on quantity |

| Itme | Surface finishing | Surface finishing methods | Main application |

| NO.1 | HR | Heat treatment after hot rolling, pickling, or with treatment | For without the purpose of the surface gloss |

| NO.2D | Without the SPM | Method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing | General materials,building materials. |

| NO.2B | After SPM | Giving No.2 processing materials appropriate method of cold light sheen | General materials, building materials ( most of the goods are processed ) |

| BA | Bright annealed | Bright heat treatment after cold rolling , in order to be more shiny, cold light effect | Automotive parts, home appliances, vehicles, medical equipment, food equipment |

| NO.3 | Shiny, coarse grain processing | The NO.2D or NO.2B processing timber No. 100-120 polishing abrasive grinding belt | Building materials, kitchen supplies |

| NO.4 | After CPL | The NO.2D or NO.2B processing timber No. 150-180 polishing abrasive grinding belt | Building materials, kitchen supplies, vehicles, medical equipment, food equipment |

| 240# | Grinding of fine lines | The NO.2D or NO.2B processing timber 240 polishing abrasive grinding belt | Kitchen appliances |

| 320# | More than 240 lines of grinding | The NO.2D or NO.2B processing timber 320 polishing abrasive grinding belt | Kitchen appliances |

| 400# | Close to BA luster | The MO.2B timber 400 polishing wheel polishing method | Building materials, kitchen utensils |

| HL | Polishing line having a long continuous processing | In a suitable size ( usually mostly No. 150-240 grit ) abrasive tape for as long as the hair, having a continuous processing method of polishing line | The most common building materials processing |

| (hair lines) | |||

| NO.6 | NO.4 processing less than the reflection , the extinction | NO.4 processing material used for polishing Tampico brushing | Building materials, decorative |

| NO.7 | Highly accurate reflectance mirror processing | No. 600 of the rotary buff with a polishing | Building materials, decorative |

| NO.8 | Highest reflectivity mirror finish | Fine particles of abrasive material in order polishing , mirror polishing with a polishing | Building materials, decorative, mirrors |

The production process of stainless steel pipes is mainly divided into three steps

1. Steel sintering: Sintering stainless steel raw materials (carbon steel or alloy steel) into stainless steel materials after heat treatment to achieve the required properties, which are the most critical characteristics of stainless steel. Sintered steel is mainly added with additives such as ore powder, small stones, sodium silicate, etc., and then heated and melted before cooling

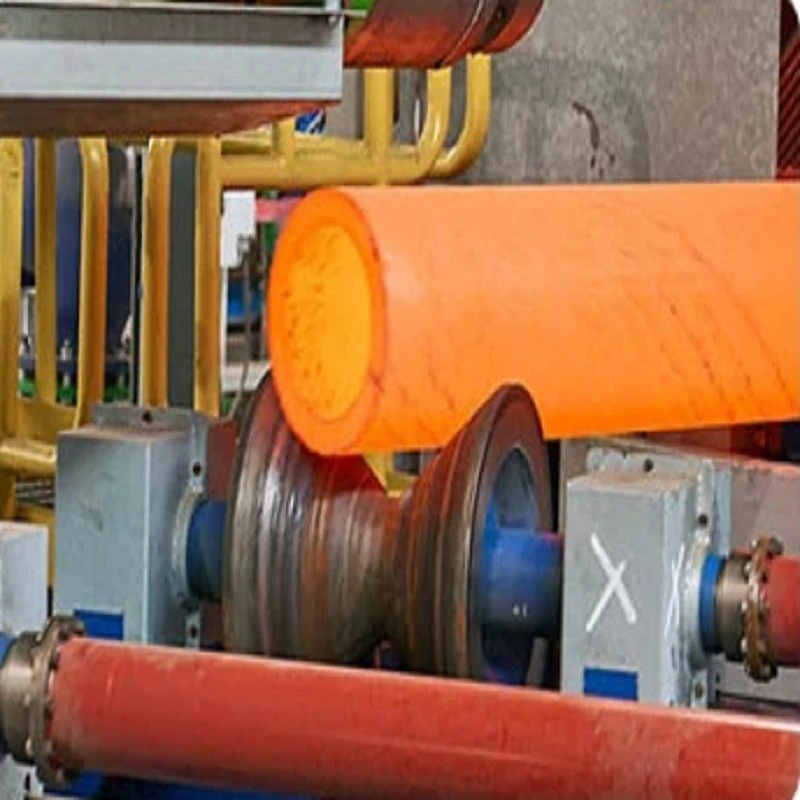

2. Stretching processing: After stretching processing, stainless steel materials are formed, usually through two processes of cold and hot drawing, resulting in good material quality, smooth surface, and high accuracy.

3. Heat treatment: Apply appropriate heat treatment to the stretched stainless steel material to increase its corrosion resistance, wear resistance, tensile strength, and other characteristics, in order to achieve high-quality stainless steel product standards.

1. Steel sintering: Sintering stainless steel raw materials (carbon steel or alloy steel) into stainless steel materials after heat treatment to achieve the required properties, which are the most critical characteristics of stainless steel. Sintered steel is mainly added with additives such as ore powder, small stones, sodium silicate, etc., and then heated and melted before cooling

2. Stretching processing: After stretching processing, stainless steel materials are formed, usually through two processes of cold and hot drawing, resulting in good material quality, smooth surface, and high accuracy.

3. Heat treatment: Apply appropriate heat treatment to the stretched stainless steel material to increase its corrosion resistance, wear resistance, tensile strength, and other characteristics, in order to achieve high-quality stainless steel product standards.

Shengtian Industry Limited is located in Hebei, China. It is a group company integrating R&D, production, sales, service and logistics. With a workshop of 8,000 square meters and 2,000 employees, it is an enterprise with the most development potential.

Shengtian Industry Limited has invested a total of 300 million yuan to build production lines and advanced equipment. There are 12 existing production lines with an annual production capacity of 5 million tons. The main products are steel plate,steel coil,round steel,structural steel,flat steel and so on.

We have rich experience in foreign trade, the main markets are in North America, South America, Africa, Southeast Asia and Oceania. Adhering to the principle of "quality first, customer first, technology first, service first" to ensure the stability and reliability of products. Creating value for customers and building a first-class brand is the company's eternal pursuit.

Shengtian Industry Limited has invested a total of 300 million yuan to build production lines and advanced equipment. There are 12 existing production lines with an annual production capacity of 5 million tons. The main products are steel plate,steel coil,round steel,structural steel,flat steel and so on.

We have rich experience in foreign trade, the main markets are in North America, South America, Africa, Southeast Asia and Oceania. Adhering to the principle of "quality first, customer first, technology first, service first" to ensure the stability and reliability of products. Creating value for customers and building a first-class brand is the company's eternal pursuit.

Packing and shipping

1.Export sea worthy package + water proof paper + wooden pallet

2 Max Loading 26.5mt for each 20Gp container

3.Safe loading and fixing Prolessional teams

4 Professional shipping line

Delivery:5-7 days after confirming the order or according to your orderquantity

Port of shipment shanghai

Remark: Insurance is al risk and accept the third party tes!

1.Export sea worthy package + water proof paper + wooden pallet

2 Max Loading 26.5mt for each 20Gp container

3.Safe loading and fixing Prolessional teams

4 Professional shipping line

Delivery:5-7 days after confirming the order or according to your orderquantity

Port of shipment shanghai

Remark: Insurance is al risk and accept the third party tes!

1. How can I get a quotation from you ?

You can leave us message, and we will reply every message in time . Or we may talk on line by Trademanager . And you can also find our contact information on contact page .

2. Can I get samples before order ?

Yes, of course. Usually our samples are free . we can produce by your samples or technical drawings . We can build the molds and fixtures .

3. What is your delivery time ?

A. The time of delivery is usually around 1 month(1*40FT as usual) ;

B. We can send out in 2 days , if it has stock .

4. What is your payment terms ?

Our usual payment term is 30% deposite, and rest against B/L. L/C is also acceptatble .

5. How can you garantee what I got will be good ?

We are factory with 100% pre-delivery inspection which garantee the quality .

6. How do you make our business long-term and good relationship ?

A.We keep good quality and competitive price to ensure our customers benefit ;

B.We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from

You can leave us message, and we will reply every message in time . Or we may talk on line by Trademanager . And you can also find our contact information on contact page .

2. Can I get samples before order ?

Yes, of course. Usually our samples are free . we can produce by your samples or technical drawings . We can build the molds and fixtures .

3. What is your delivery time ?

A. The time of delivery is usually around 1 month(1*40FT as usual) ;

B. We can send out in 2 days , if it has stock .

4. What is your payment terms ?

Our usual payment term is 30% deposite, and rest against B/L. L/C is also acceptatble .

5. How can you garantee what I got will be good ?

We are factory with 100% pre-delivery inspection which garantee the quality .

6. How do you make our business long-term and good relationship ?

A.We keep good quality and competitive price to ensure our customers benefit ;

B.We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from