Basic Info.

Model NO.

standard and non standard sizes

Controlling Mode

CNC

Surface Treatment

Unground,Ground

Application

End Mill,Drill Bit,Hand Tools,etc.

Milling Cutter Structure

Indexable Type

Grade

Yg6, Yg8, Yg10,Yl10.2,Yg12,Yg15

Automatic Grade

Semiautomatic

Sizes

D1-30X330mm

Precision

High Precision

Tolerance

H6,H7,etc.

Object

Steel

Transport Package

Plastic & Carton

Specification

33x23x19cm

Trademark

G&W

Origin

Zhuzhou China

HS Code

8466910000

Production Capacity

30 Tons Per Year

Product Description

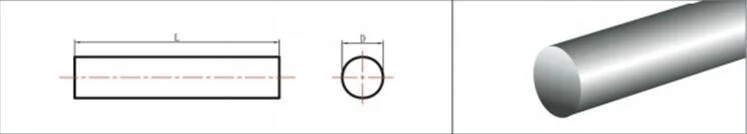

330mm Blank Solid Tungsten Carbide Rod

Solid Rods (Metric) 330mm

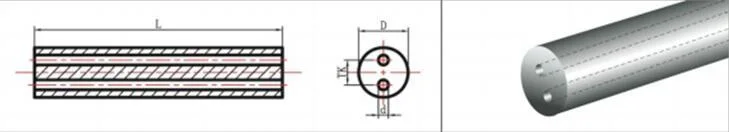

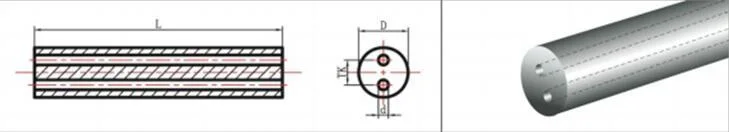

Two straight coolant ducts rods, Reduced TK

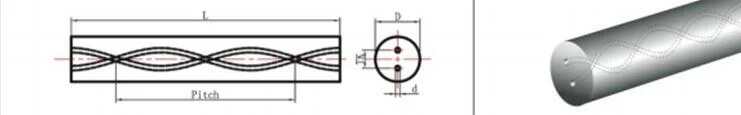

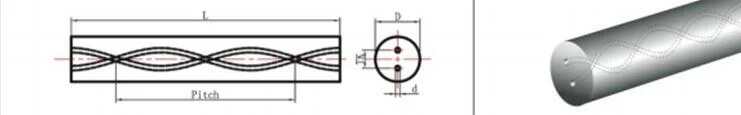

30° Two Helical Coolant Ducts(Type HE-30°)

*all sizes are available, with sintered, grinding, polishing, large ready stock for immediately delivery!

* GU10 and GU 20 are the most popular and common grades, they are ready for your factric of carbide end mills and carbide drills!

* tungsten carbide rods / cemented carbide rods/ solid carbide rods

Size:

Diameter: 0.5mm-50mm (HIP Extrusion)

Standard Length: cut to length, length from 50-1000mm,

Widely used in endmills, drills, PCB drills, PCB routers etc.

Advantages of our carbide products:

1. high quality durable tungsten carbide rods/cemented rods for milling for router bits made from 100% virgin raw material.

2. produced with advanced equipments and process.

3. all products go through in-process and final inspection.

4. free online technical service available.

5. stable and continuous production ability.

| Grade | ISO range | Cobalt % | Density g/cm3 | Hardness HRA | TRS N/mm2 |

| YG8 | K30 | 8 | 14.80 | 89.5 | 2200 |

| YG6 | K20 | 6 | 14.95 | 90.5 | 1900 |

| YG6X | K10 | 6 | 14.95 | 91.5 | 1800 |

| YL10.2 | K30 | 10 | 14.50 | 91.8 | 2400 |

| YG13X | K30-K40 | 13 | 14.30 | 89.5 | 2600 |

| YG15 | K40 | 15 | 14.00 | 87.5 | 2800 |

Solid Rods (Metric) 330mm

| Unground | h6 | L | Tol. | Unground | h6 | L | Tol. | ||

| D | Tol. | D | Tol. | ||||||

| Ø2.2 | +0.3/+0 | 2.0 | 330 | +5/+0 | Ø17.2 | +0.3/+0 | 17 | 330 | +5/+0 |

| Ø3.2 | +0.3/+0 | 3.0 | 330 | +5/+0 | Ø18.2 | +0.3/+0 | 18 | 330 | +5/+0 |

| Ø4.2 | +0.3/+0 | 4.0 | 330 | +5/+0 | Ø19.2 | +0.3/+0 | 19 | 330 | +5/+0 |

| Ø5.2 | +0.3/+0 | 5.0 | 330 | +5/+0 | Ø20.2 | +0.3/+0 | 20 | 330 | +5/+0 |

| Ø6.2 | +0.3/+0 | 6.0 | 330 | +5/+0 | Ø21.2 | +0.3/+0 | 21 | 330 | +5/+0 |

| Ø7.2 | +0.3/+0 | 7.0 | 330 | +5/+0 | Ø22.2 | +0.3/+0 | 22 | 330 | +5/+0 |

| Ø8.2 | +0.3/+0 | 8.0 | 330 | +5/+0 | Ø23.2 | +0.3/+0 | 23 | 330 | +5/+0 |

| Ø9.2 | +0.3/+0 | 9.0 | 330 | +5/+0 | Ø24.2 | +0.3/+0 | 24 | 330 | +5/+0 |

| Ø10.2 | +0.3/+0 | 10.0 | 330 | +5/+0 | Ø25.2 | +0.3/+0 | 25 | 330 | +5/+0 |

| Ø11.2 | +0.3/+0 | 11.0 | 330 | +5/+0 | Ø26.2 | +0.3/+0 | 26 | 330 | +5/+0 |

| Ø12.2 | +0.3/+0 | 12.0 | 330 | +5/+0 | Ø27.2 | +0.3/+0 | 27 | 330 | +5/+0 |

| Ø13.2 | +0.3/+0 | 13.0 | 330 | +5/+0 | Ø28.2 | +0.3/+0 | 28 | 330 | +5/+0 |

| Ø14.2 | +0.3/+0 | 14.0 | 330 | +5/+0 | Ø29.2 | +0.3/+0 | 29 | 330 | +5/+0 |

| Ø15.2 | +0.3/+0 | 15.0 | 330 | +5/+0 | Ø30.2 | +0.3/+0 | 30 | 330 | +5/+0 |

| Ø16.2 | +0.3/+0 | 16.0 | 330 | +5/+0 | |||||

Two straight coolant ducts rods, Reduced TK

| Unground | Ground h6 | TK | Tol. | D | Tol. | L | a | |

| D | Tol. | |||||||

| 6.3 | +0.3/0 | 6.0 | 1.5 | 0/-0.20 | 0.80 | ±0.15 | 330 | 0.15 |

| 7.3 | 7.0 | 1.5 | 0.80 | 0.15 | ||||

| 8.3 | 8.0 | 2.6 | 0/-0.30 | 1.00 | 0.15 | |||

| 9.3 | 9.0 | 2.6 | 1.00 | 0.20 | ||||

| 10.3 | 10.0 | 2.6 | 1.00 | 0.20 | ||||

| 11.3 | +0.4/0 | 11.0 | 3.5 | 1.20 | 0.28 | |||

| 12.3 | 12.0 | 3.5 | 1.20 | 0.30 | ||||

| 13.3 | 13.0 | 3.5 | 1.20 | 0.34 | ||||

| 14.3 | 14.0 | 5.0 | 1.50 | 0.37 | ||||

| 15.3 | 15.0 | 5.0 | 1.50 | 0.40 | ||||

| 16.3 | 16.0 | 5.0 | 1.50 | ±0.20 | 0.40 | |||

| 17.3 | +0.5/0 | 17.0 | 6.2 | 2.00 | 0.47 | |||

| 18.3 | 18.0 | 6.2 | 2.00 | 0.50 | ||||

| 19.3 | 19.0 | 6.2 | 2.00 | 0.50 | ||||

| 20.3 | 20.0 | 6.2 | 0/-0.40 | 2.00 | ±0.30 | 0.50 | ||

30° Two Helical Coolant Ducts(Type HE-30°)

| Unground | Ground h6 | L Tol. +5.0 | TK | Tol. | D | Tol. | Pitch | |

| D | Tol. | |||||||

| 6.3 | +0.4/+1.0 | 6.0 | 330 | 2.7 | ±0.2 | 0.80 | ±0.15 | 32.65 |

| 7.3 | 7.0 | 330 | 3.5 | 1.00 | 38.09 | |||

| 8.3 | 8.0 | 330 | 3.4 | 1.00 | 43.53 | |||

| 9.3 | 9.0 | 330 | 4.5 | ±0.3 | 1.40 | 48.97 | ||

| 10.3 | 10.0 | 330 | 4.8 | 1.30 | 54.41 | |||

| 11.3 | +0.4/+1.2 | 11.0 | 330 | 4.9 | ±0.4 | 1.40 | 59.86 | |

| 12.3 | 12.0 | 330 | 6.3 | 1.70 | 65.30 | |||

| 13.3 | 13.0 | 330 | 6.1 | 1.75 | ±0.20 | 70.74 | ||

| 14.3 | 14.0 | 330 | 6.7 | 1.80 | 76.18 | |||

| 15.3 | 15.0 | 330 | 7.3 | 1.75 | 81.82 | |||

| 16.3 | +0.4/+1.4 | 16.0 | 330 | 8.0 | 2.00 | 87.06 | ||

| 17.3 | 17.0 | 330 | 8.5 | 1.75 | ±0.25 | 92.50 | ||

| 18.3 | 18.0 | 330 | 9.0 | 2.30 | 97.95 | |||

| 19.3 | 19.0 | 330 | 9.7 | 2.00 | 103.39 | |||

| 20.3 | 20.0 | 330 | 10.0 | ±0.5 | 2.50 | 108.83 | ||

*all sizes are available, with sintered, grinding, polishing, large ready stock for immediately delivery!

* GU10 and GU 20 are the most popular and common grades, they are ready for your factric of carbide end mills and carbide drills!

* tungsten carbide rods / cemented carbide rods/ solid carbide rods