Basic Info.

Model NO.

S20C 45SC SCM440 1020 1045 4140

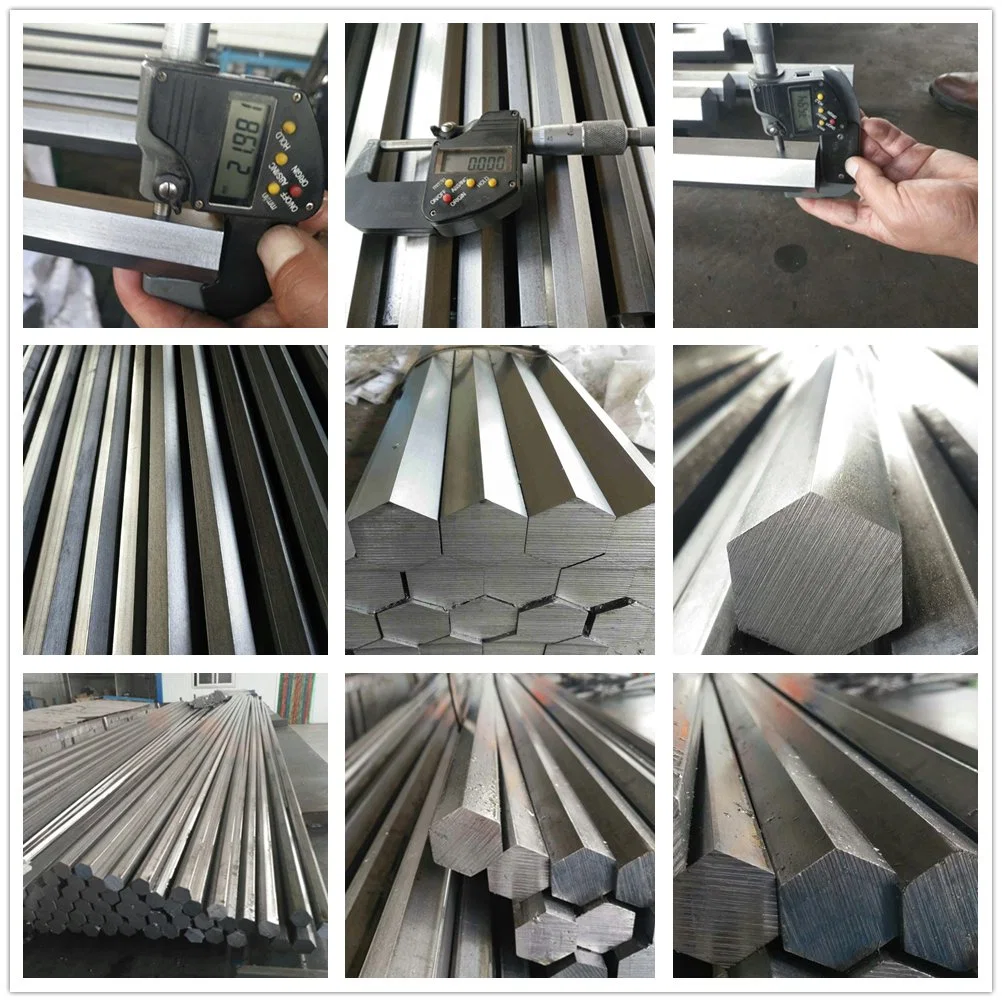

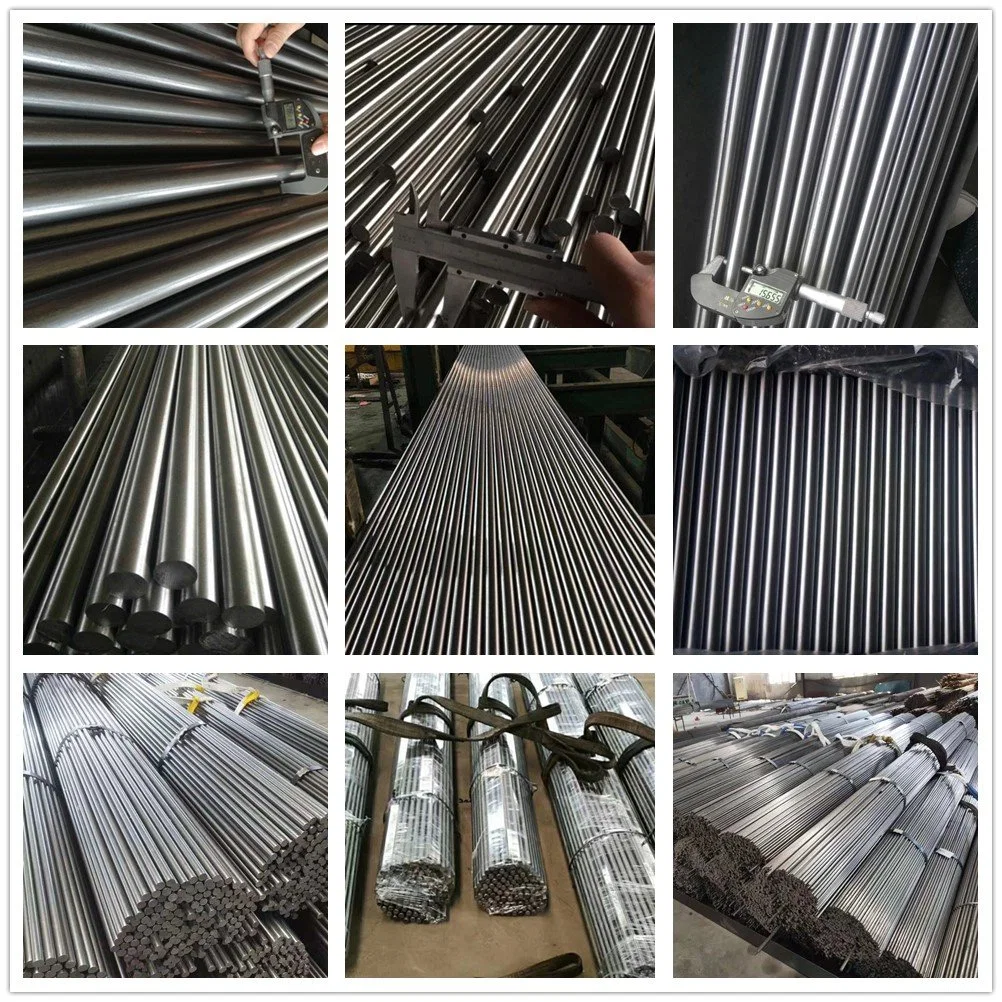

Surface

Cold Drawn Bright

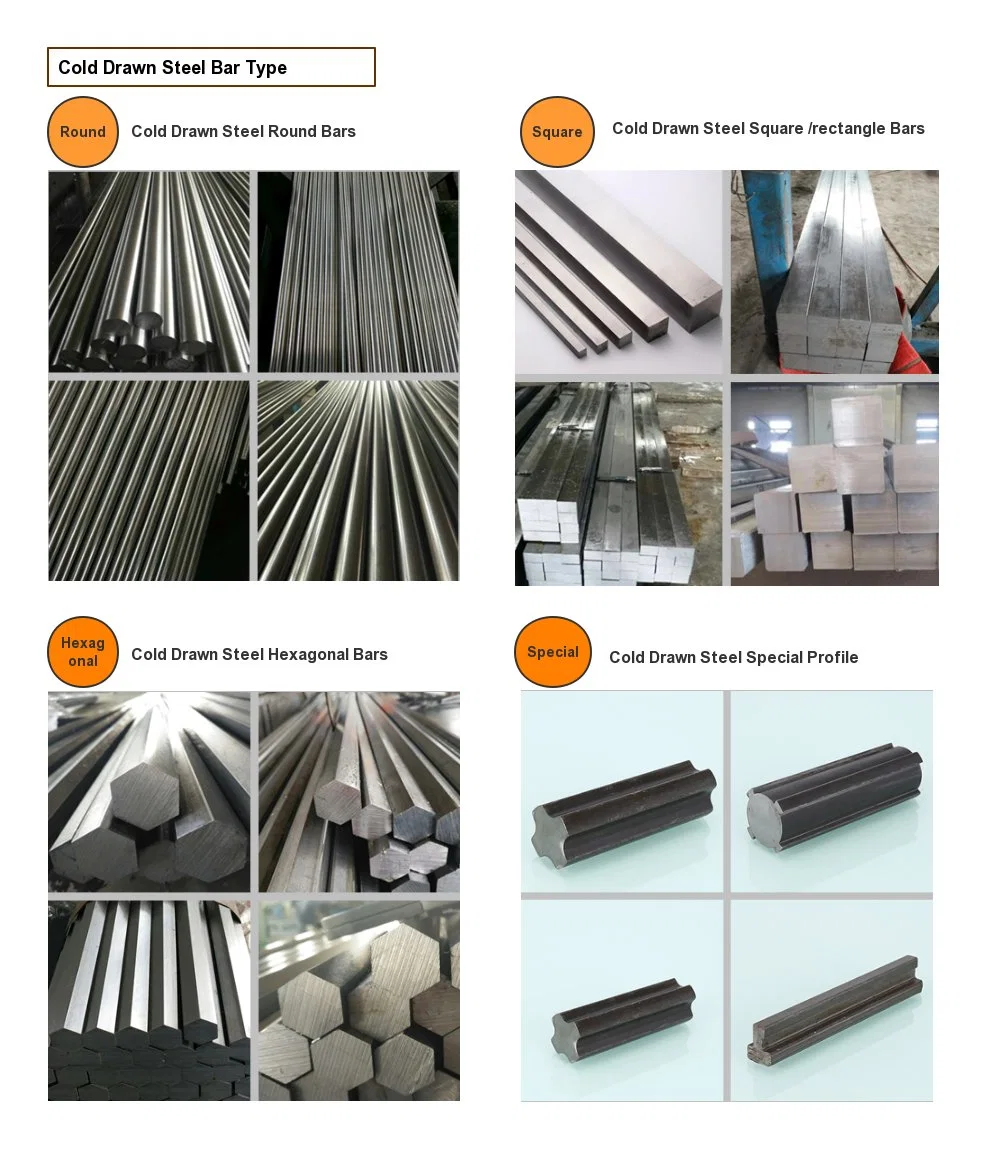

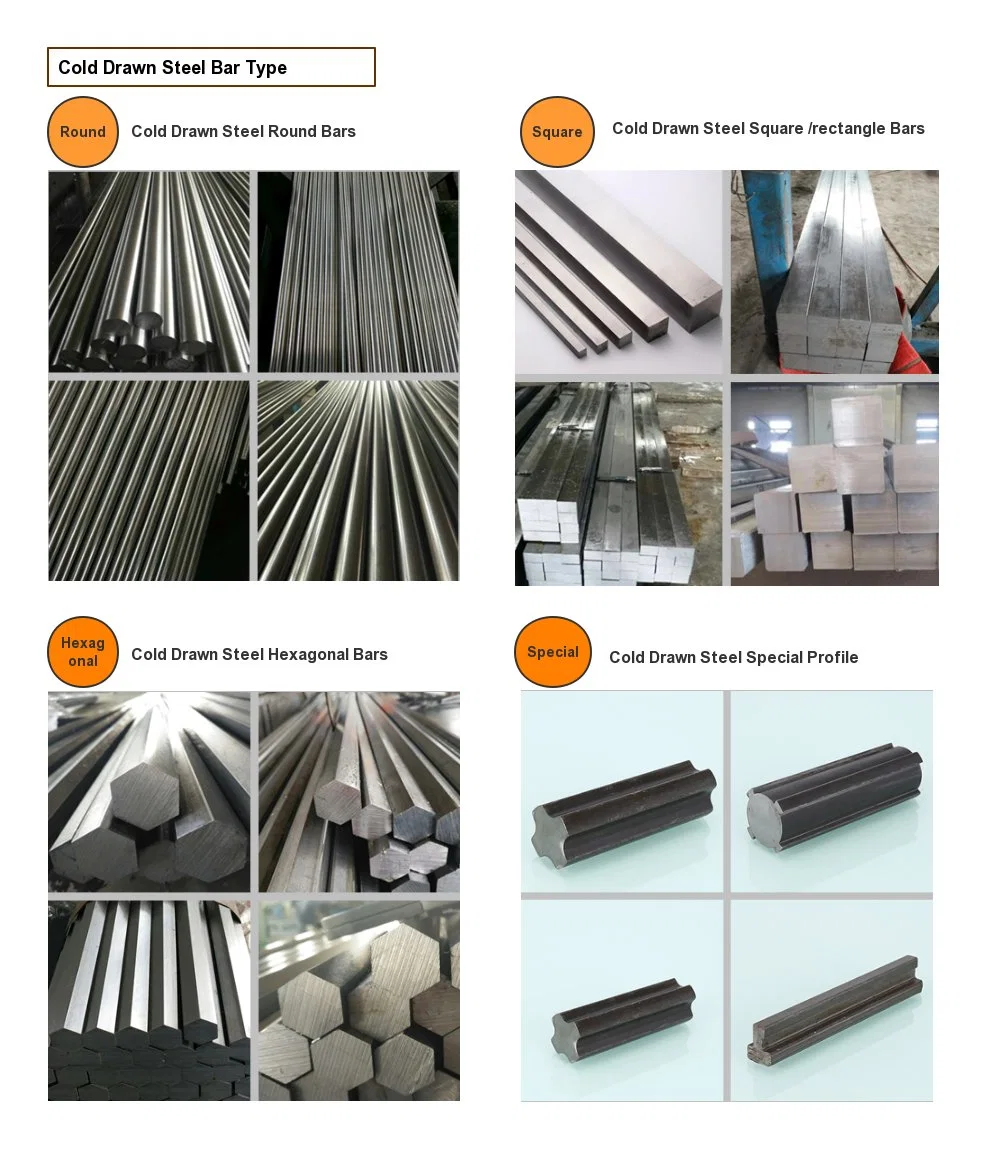

Shapes

Round, Square, Hex

MOQ

1ton

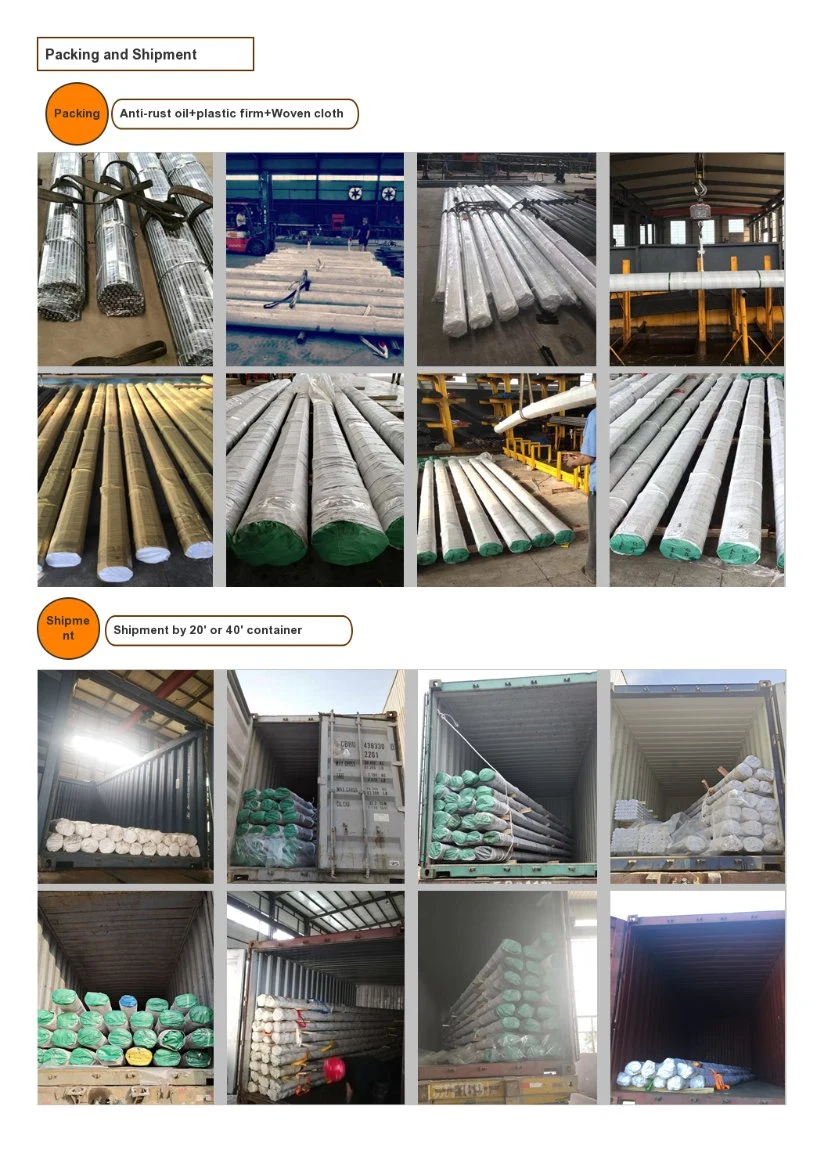

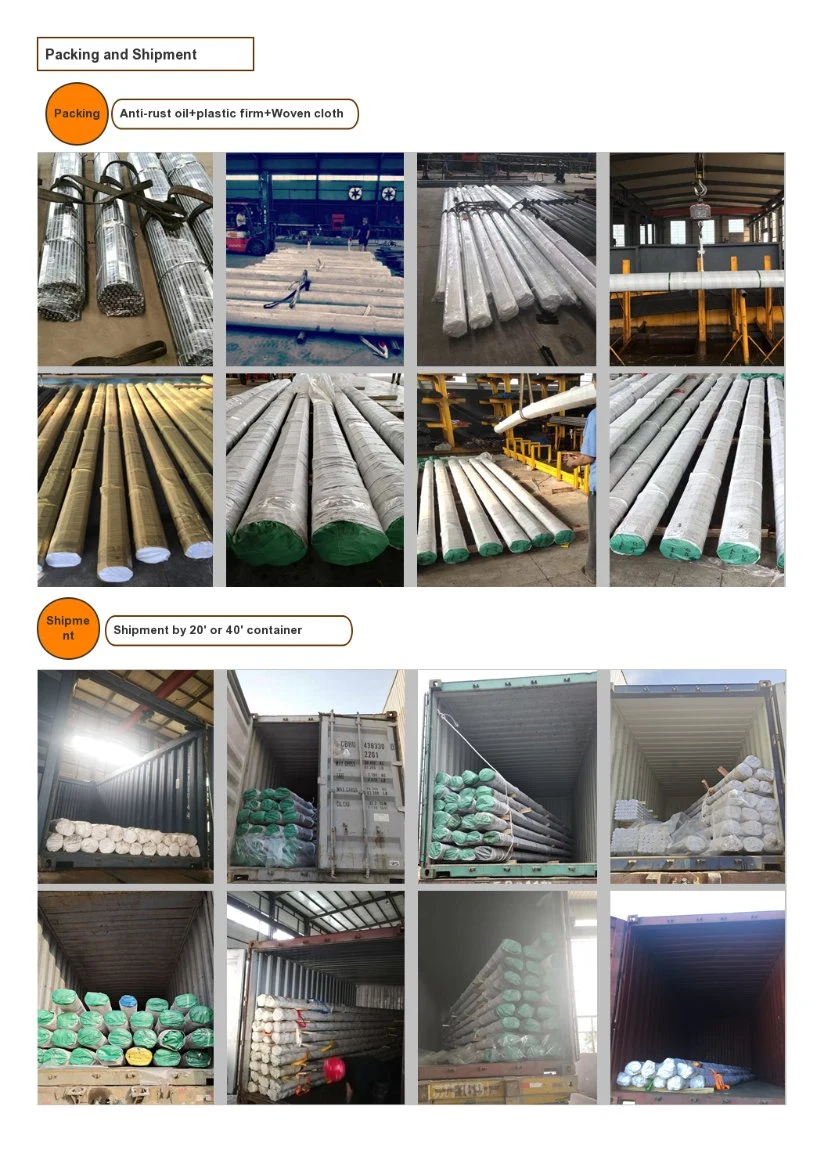

Transport Package

Anti-Rust Packing

Specification

0.5mm-100mm

Origin

China

Production Capacity

3000tons/Month

Product Description

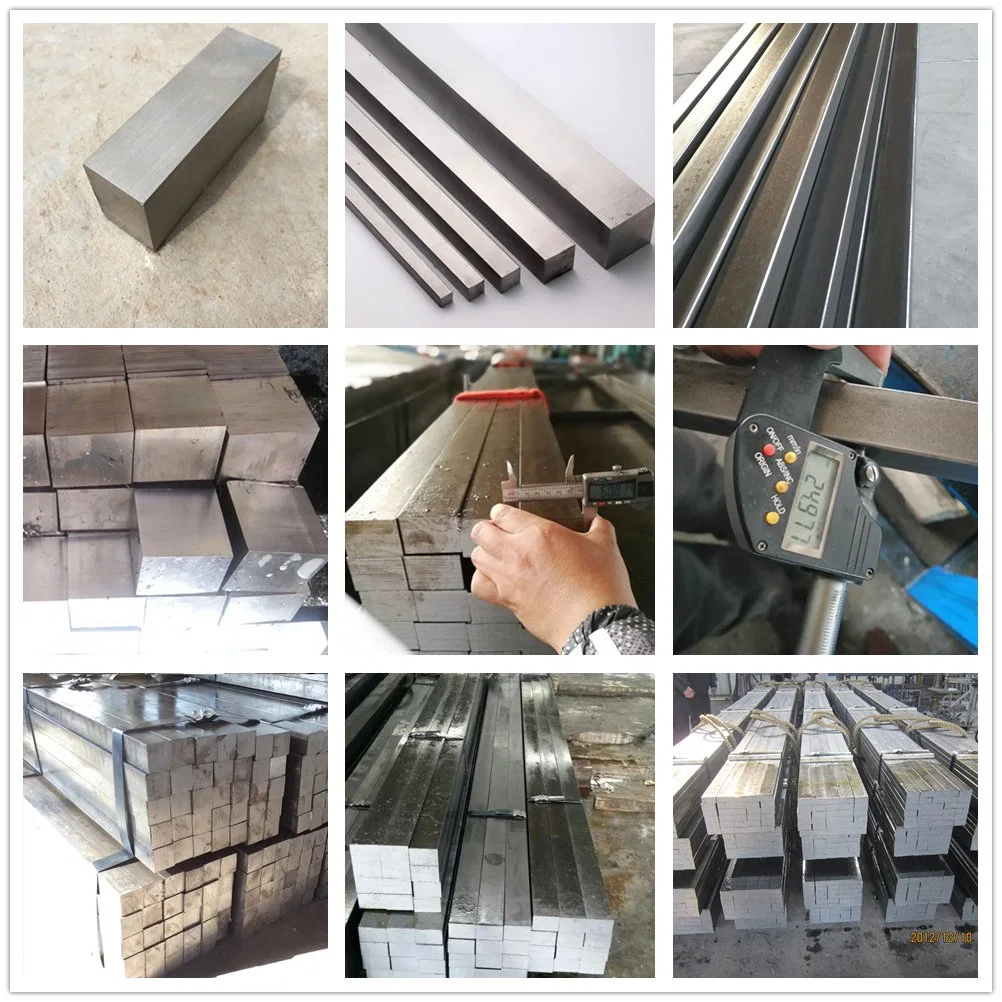

S20c S45c Scm440 1020 1045 4140 Cold Rolled Steel Hexagonal Bar / Cold Drawn Hex Steel

1.Processing for Cold Drawn Hexagonal Steel Bars

hot rolled bars/wire rods - (spheroidizing annealed for alloy steel/bearing steel) - pickling - cleaning - saponifing - cold drawn - (softening annealed for alloy steel/bearing steel) - cutting - bundling - packing - finished products

2.The advantages of Cold Drawn Steel Bars

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.

3.SAE 1045 / S45C / C45 steel chemical composition

4.Sizes we can offer for cold drawn steel bars

5.MOQ:1ton per size

6.Delivery time : usually, 7-10 days for stocks, and one month for new production.

7.Payment term:TT or LC

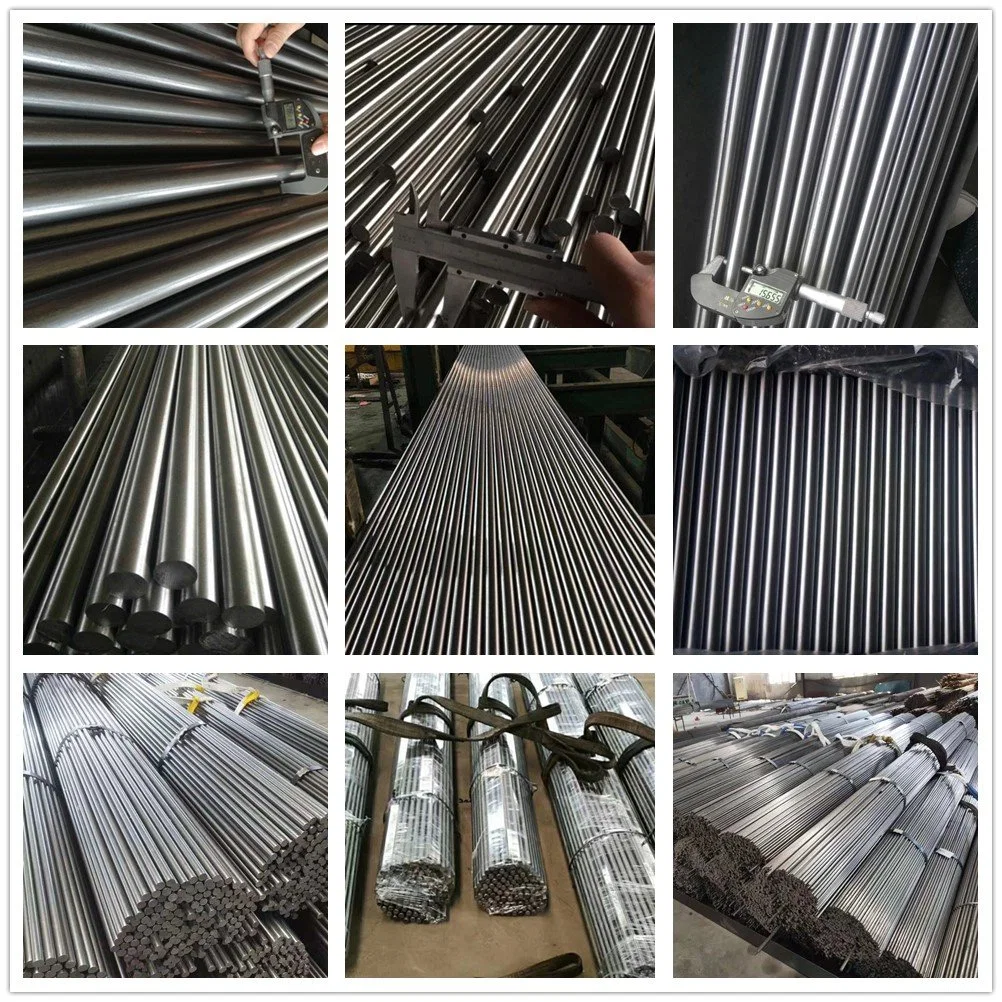

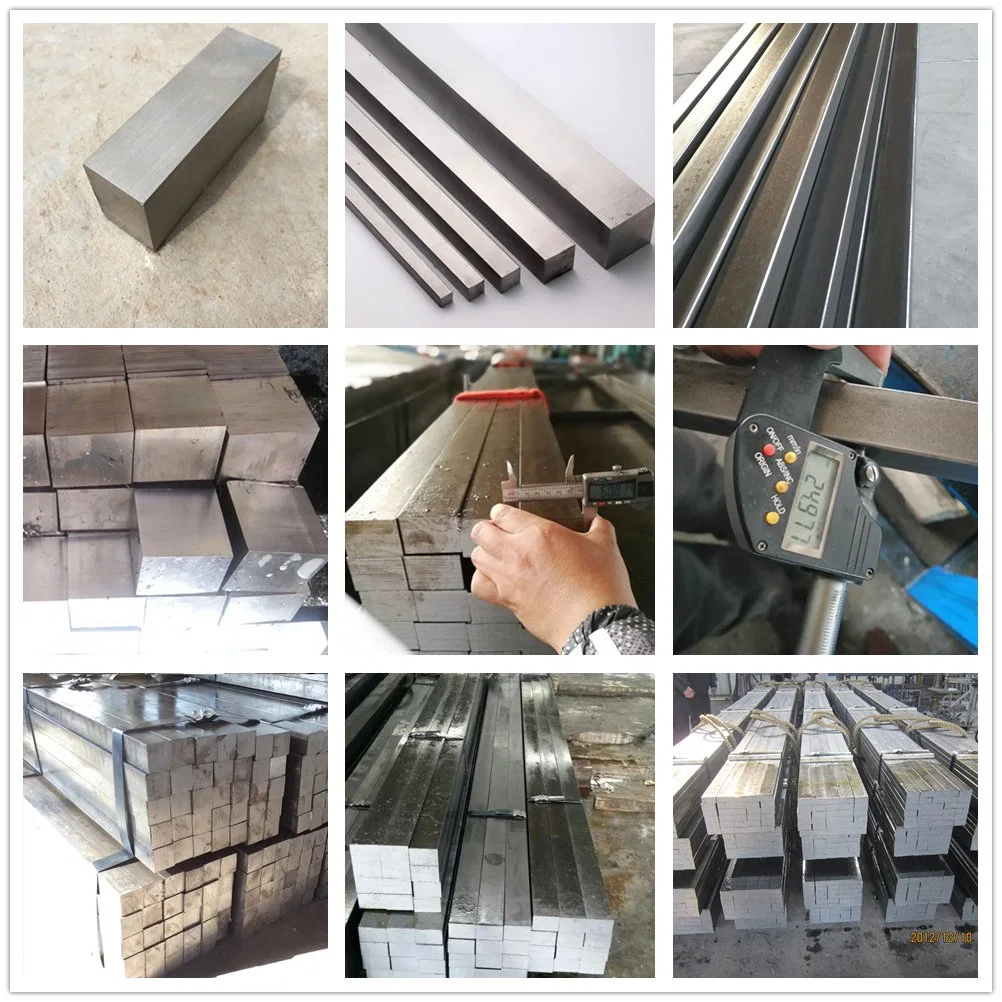

8.Cold Drawn Steel Bar Packing : Rusty proof packages. Anti rusty oil painting, film wrapped inside and Nylon plastic bags wrapped outside

9.Applications for cold drawn steel bars:

Alternator Shafts, BearingsCoil, SpringsConcrete, Accessories ,Electric Motor Shafts,Fasteners,Forging Applications,Hand Tools,Hydraulic Hose Fittings,MacPherson Strut Shafts,Oil Pump Shafts,Precision Machined Parts,Printer Shafts,Roller Conveyor Axles,Shock Absorber Shafts,Shotgun & Rifle Barrels,Stabilizer Bars,Starter Motor Shafts,Steering LinkagesTransmission Shafts,Vehicle Axles,Water Pump Shafts,Wheel Spindles etc

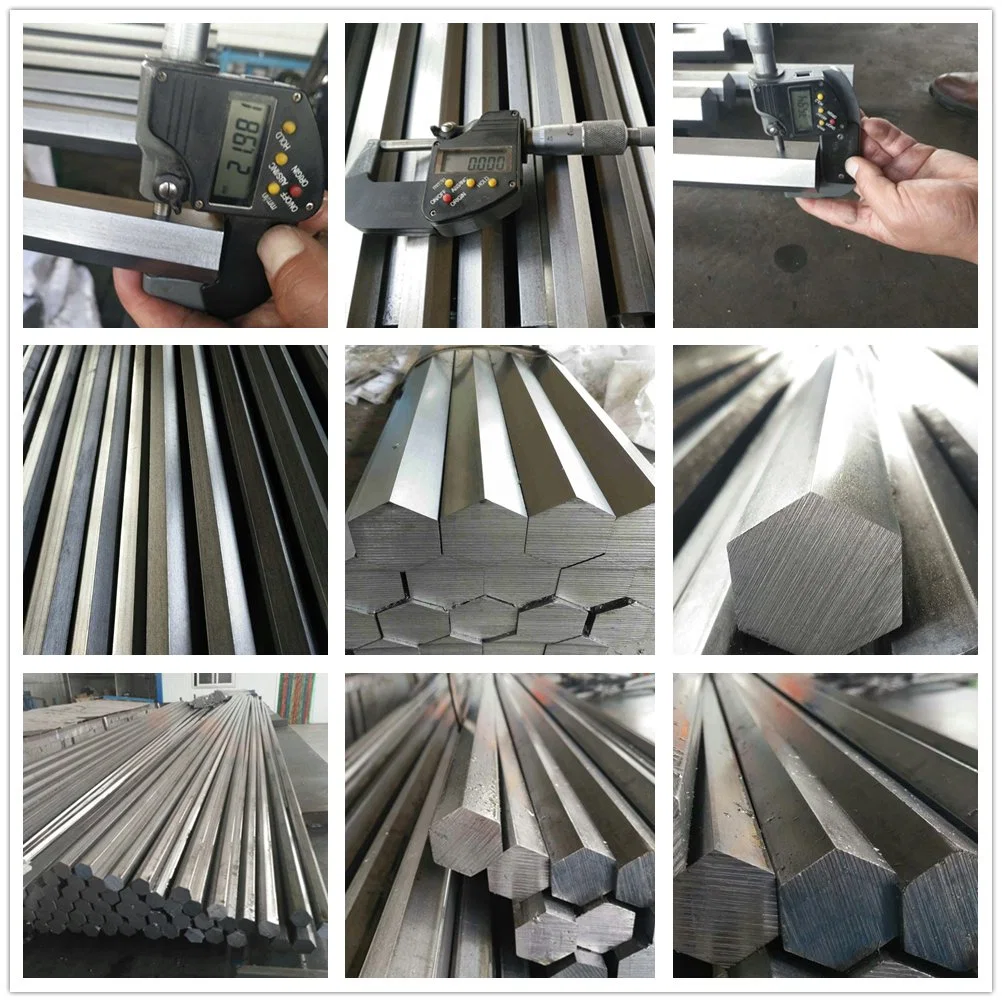

10.Tolerance for cold drawn steel bars:

\

1.Processing for Cold Drawn Hexagonal Steel Bars

hot rolled bars/wire rods - (spheroidizing annealed for alloy steel/bearing steel) - pickling - cleaning - saponifing - cold drawn - (softening annealed for alloy steel/bearing steel) - cutting - bundling - packing - finished products

2.The advantages of Cold Drawn Steel Bars

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.

3.SAE 1045 / S45C / C45 steel chemical composition

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 1020 | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | Max 0.030 | Max 0.030 | Max 0.25 | |

| 1045 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | Max 0.030 | Max 0.030 | Max 0.25 | |

| 4140 | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | Max 0.030 | Max 0.030 | 0.9-1.2 | 0.15-0.25 |

4.Sizes we can offer for cold drawn steel bars

| Shapes | Sizes | Processing |

| Steel Round Bar | 5mm to 63.5mm | Cold Drawn |

| Steel Round Bar | 63.5mm-120mm | smooth-turned and polished. |

| cold drawn steel square bar | 5*5mm to 120*120mm | Cold Drawn |

| cold drawn steel hex bar | 5mm to 120mm | Cold Drawn |

| cold drawn steel hexagonal bar | 5mm to 120mm(side to side) | Cold Drawn |

5.MOQ:1ton per size

6.Delivery time : usually, 7-10 days for stocks, and one month for new production.

7.Payment term:TT or LC

8.Cold Drawn Steel Bar Packing : Rusty proof packages. Anti rusty oil painting, film wrapped inside and Nylon plastic bags wrapped outside

9.Applications for cold drawn steel bars:

Alternator Shafts, BearingsCoil, SpringsConcrete, Accessories ,Electric Motor Shafts,Fasteners,Forging Applications,Hand Tools,Hydraulic Hose Fittings,MacPherson Strut Shafts,Oil Pump Shafts,Precision Machined Parts,Printer Shafts,Roller Conveyor Axles,Shock Absorber Shafts,Shotgun & Rifle Barrels,Stabilizer Bars,Starter Motor Shafts,Steering LinkagesTransmission Shafts,Vehicle Axles,Water Pump Shafts,Wheel Spindles etc

10.Tolerance for cold drawn steel bars:

| Size In mm | Tolerance In mm | |||

| h8 | h9 | h10 | h11 | |

| 6-10 | 0/-0.022 | 0/-0.036 | 0/-0.058 | 0/-0.090 |

| 10-18 | 0/-0.027 | 0/-0.043 | 0/-0.070 | 0/-0.110 |

| 18-30 | 0/-0.033 | 0/-0.052 | 0/-0.084 | 0/-0.130 |

| 30-50 | 0/-0.039 | 0/-0.062 | 0/-0.100 | 0/-0.160 |

| 50-100 | 0/-0.046 | 0/-0.074 | 0/-0.120 | 0/-0.190 |

\