- Overview

- Product Introduction

- Product Specification

- Product Display

- Application Scope

- Packaging And Transportation

- FAQ

Basic Info.

Model NO.

S235JR/S235J0/S235J2

Processing Service

Bending, Welding, Decoiling, Cutting, Punching

Tolerance

±1%

MOQ

3 Tons

Stock

Big Stock

Transport Package

Standard Seaworthy Packing

Trademark

GZ STEEL

Origin

Shandong, China

Production Capacity

10000 Tons Per Month

Product Description

Short for "reinforcing bar," rebar is refers to metal - usually steel - that's used to help increase the tensile strength of concrete for a variety of needs, including many of the most common construction types you see every day.

Short for "reinforcing bar," rebar is refers to metal - usually steel - that's used to help increase the tensile strength of concrete for a variety of needs, including many of the most common construction types you see every day.Concrete is known to be weak in the areas we just mentioned, at least compared to steel and other metal types. If this reinforcement was not used, these structures would at-risk of falling apart.

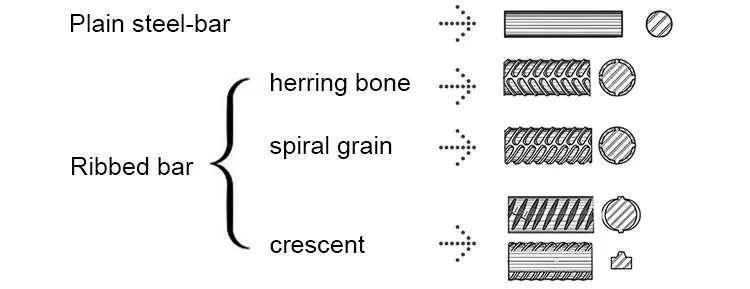

Rebar usually will be built so the metal component is not visible within the structure. Rather, it will be buried within the concrete. It's usually made with ribs rather than smoothly, allowing it to avoid slippage within its structure.

How Rebar is Made

As we noted above, the most common material for rebar use is steel, which is used because of its excellent tensile properties. It's often made from forms of recycled steel, which will be melted down using an electric arc furnace, cooled using billets, and then stored until it's needed.

From here, billets can be reheated to an elevated temperature and fed through extrusion tools, then necked down until its proper size is reached. Finally, it will be tooled to create the proper ribbing, which we noted above is in place to prevent slippage within concrete. Then it will be sheared to the proper length, and it's ready to go.

| Product Name | STEEL REBAR |

| Standard | GB1449.2-2007, BS4449:1997, JIS G3112-2004, ASTM A615-A615M-04a |

| Grade | HRB335, HRB400, HRB500, HRB600, GR460B, SD295, SD360, SD390, SD400, SD500, ASTM A615 GR40/GR60/GR75 |

| Material | Q235, Q345, SS400, ST37-2, ST52, Q420, Q460, S235JR, S275JR, S355JR |

| Diameter | 10-50mm |

| Length | 6m, 9m, 12m or cut according to client's requirement |

| Model Number | φ12,φ14,φ16,φ18,φ20,φ22,φ25,φ32,φ36,φ38,φ40,φ50 |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Application | Construction, Building, Bridge, House Decoration |

| Package | Packed in bundle, standard seaworthy package or customers' requirements. |

| Payment Terms | 30%TT Advance + 70% Balance |

| Grade | Technical data of the original chemical composition (%) | |||||

| HRB335 | C | Mn | Si | Cr | P | S |

| 0.17~0.25 | 1.00~1.60 | 0.40~0.80 | 0.30~0.40 | 0.045 Max. | 0.045 Max. | |

| Physics Capability | ||||||

| Yield strength | Tensile strength | Elongation | ||||

| ≥ 335 Mpa | ≥ 490 Mpa | ≥ 16% | ||||

| HRB400 | C | Mn | Si | Cr | P | S |

| 0.17~0.25 | 1.20~1.60 | 0.20~0.80 | 0.30~0.40 | 0.045 Max. | 0.045 Max. | |

| Physics Capability | ||||||

| Yield strength | Tensile strength | Elongation | ||||

| ≥ 400 Mpa | ≥ 570 Mpa | ≥ 14% | ||||

| HRB500 | C | Mn | Si | Cr | P | S |

| 0.25 Max. | 1.60 Max. | 0.80 Max. | 0.30~0.40 | 0.045 Max. | 0.045 Max. | |

| Physics Capability | ||||||

| Yield strength | Tensile strength | Elongation | ||||

| ≥ 500 Mpa | ≥ 630 Mpa | ≥ 12% | ||||

Rebar, or reinforcing bar, is used in many masonry and concrete projects to reinforce slabs and structures. Because concrete has low compressive strength, rebar helps it bear loads without cracking.

Therefore, for most concrete projects, rebar is required to help the slab, footer, or foundation maintain its structural integrity. Rebar is available in standard sizes, making it easy to find the weight and dimensions of the rebar for your project.

The first step is to identify which size of rebar is being used on the project, for example, a #3 rebar. Most home and residential projects will use #3, #4 or #5 rebar, with #3 being used most commonly for patios and driveways, #4 for walls and columns, and #5 for footers and foundations.

The next step is to identify how much linear footage of rebar will be used. Linear footage is the total amount of length in 12″ increments needed for the project.

For example, if you need 20 pieces of 60′ rebar, you will need 1,200 linear feet of material. Rebar is typically sold in 20′, 30′, 40′, and 60′ lengths, but it is possible to order custom lengths as well.

Refer to the charts below for the dimensions for each size of rebar. Find the diameter and area of the rebar along with the weight per linear foot. To find the total weight, multiply the total length of rebar - total linear feet of material used - with the weight per linear foot if measured in feet, or weight per meter if measured in meters.

| US Rebar Weight and Dimensions | |||||||

| Imperial Bar Size | "Soft" Metric Size | Weight | Nominal Diameter | Nominal Area | |||

| lb/ft | kg/m | inch | mm | inch² | mm² | ||

| #2 | #6 | 0.167 | 0.249 | 0.250 = 1/4" | 6.35 | 0.05 | 32 |

| #3 | #10 | 0.376 | 0.561 | 0.375 = 3/8" | 9.525 | 0.11 | 71 |

| #4 | #13 | 0.668 | 0.996 | 0.500 = 1/2" | 12.7 | 0.20 | 129 |

| #5 | #16 | 1.043 | 1.556 | 0.625 = 5/8" | 15.875 | 0.31 | 200 |

| #6 | #19 | 1.502 | 2.24 | 0.750 = 3/4" | 19.05 | 0.44 | 284 |

| #7 | #22 | 2.044 | 3.049 | 0.875 = 7/8" | 22.225 | 0.60 | 387 |

| #8 | #25 | 2.670 | 3.982 | 1.000 = 1″ | 25.4 | 0.79 | 509 |

| #9 | #29 | 3.400 | 5.071 | 1.128 = 1 1/8" | 28.65 | 1.00 | 645 |

| #10 | #32 | 4.303 | 6.418 | 1.270 = 1 1/4" | 32.26 | 1.27 | 819 |

| #11 | #36 | 5.313 | 7.924 | 1.410 = 1 3/8" | 35.81 | 1.56 | 1006 |

| #14 | #43 | 7.650 | 11.41 | 1.693 = 1 3/4" | 43 | 2.25 | 1452 |

| #18 | #57 | 13.60 | 20.284 | 2.257 = 2 1/4" | 57.3 | 4.00 | 2581 |

| Canadian Rebar Weight and Dimensions | |||

| Metric Bar Size | Weight (kg/m) | Nominal Diameter (mm) | Nominal Area (mm²) |

| 10M | 0.785 | 11.3 | 100 |

| 15M | 1.570 | 16.0 | 200 |

| 20M | 2.355 | 19.5 | 300 |

| 25M | 3.925 | 25.2 | 500 |

| 30M | 5.495 | 29.9 | 700 |

| 35M | 7.850 | 35.7 | 1000 |

| 45M | 11.775 | 43.7 | 1500 |

| 55M | 19.625 | 56.4 | 2500 |

| European Rebar Weight and Dimensions | |||

| Metric Bar Size | Weight (kg/m) | Nominal Diameter (mm) | Nominal Area (mm²) |

| 6,0 | 0.222 | 6 | 28.3 |

| 8,0 | 0.395 | 8 | 50.3 |

| 10,0 | 0.617 | 10 | 78.5 |

| 12,0 | 0.888 | 12 | 113 |

| 14,0 | 1.21 | 14 | 154 |

| 16,0 | 1.58 | 16 | 201 |

| 20,0 | 2.47 | 20 | 314 |

| 25,0 | 3.85 | 25 | 491 |

| 28,0 | 4.83 | 28 | 616 |

| 32,0 | 6.31 | 32 | 804 |

| 40,0 | 9.86 | 40 | 1257 |

| 50,0 | 15.4 | 50 | 1963 |

Quality Inspection

The testing institution tests the quality of the products to ensure that they meet the production standards. Product quality is strictly controlled by inspection personnel to ensure zero product defects.

Steel rebar are mainly subjected to tensile stress in concrete. The deformed steel bar has a greater bonding ability with concrete due to the action of the ribs, and thus can better withstand the external force. Rebar is widely used in various building structures. Especially large, heavy, lightweight thin-walled and high-rise buildings.

Steel rebar are mainly subjected to tensile stress in concrete. The deformed steel bar has a greater bonding ability with concrete due to the action of the ribs, and thus can better withstand the external force. Rebar is widely used in various building structures. Especially large, heavy, lightweight thin-walled and high-rise buildings.

The main uses of deformed steel bar

Rebar is a small type of steel, mainly used for the skeleton of reinforced concrete building components. Rebar is usually used in reinforced concrete, the effect of its stripes is to increase the friction force, make rebar and concrete bite together, form one,under the action of external force will not produce twitching phenomenon, improve the strength of concrete. Rebar is widely used in civil engineering construction such as houses, bridges and roads. From public facilities such as expressways, railways, bridges, culverts, tunnels and flood control dams to the foundation, beams, columns, walls and plates of housing buildings, threaded steel is an indispensable structural material.

We offer different modes of transport depending on the customer's destination: rail transport and ship transport, etc. The packaging is: export sea worthy package + water proof paper + wooden pallet or as customers' requirements. The Shipping Mark shall consist of: Trade mark, Seller's name, Product name, Applicable standards, Specifications, Package No., Contract No., Heat No., Production date, Weighing method, Net weight, Gross Weight, Consignee and Protection symbols, etc.

We offer different modes of transport depending on the customer's destination: rail transport and ship transport, etc. The packaging is: export sea worthy package + water proof paper + wooden pallet or as customers' requirements. The Shipping Mark shall consist of: Trade mark, Seller's name, Product name, Applicable standards, Specifications, Package No., Contract No., Heat No., Production date, Weighing method, Net weight, Gross Weight, Consignee and Protection symbols, etc.  Q1:Can you send samples?

Q1:Can you send samples? A:Of course, we can provide customers with free samples and express shipping service to all over of the world.

Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Q5:What about product prices information?

A:Prices various according to periodic price changes of raw materials.

Q6:What is your terms of payment ?

A:Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment or based on BL copy or LC at sight.

Q7:Do you provide custom made Products service?

A: Yes,if you have your own design , we can produce according to your specification and drawing.

Q8:What are the certifications for your products?

A:We have ISO 9001, MTC, third parties' inspections are all available such SGS, BV ect.

Q9:How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q10: How many countries you already exported to?

A:We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana,somalia and other African countries.Our export experience is rich, we familiar with different market demands, can help customers avoid a lot of trouble.

Q11:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q12:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q13:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion and various climate changes during ocean transportation.

Q14:What is your working time?

A:In general, When you first contacted us, our online service time is Beijing time: 8:00-22:00, after 22:00, we will reply to your inquiry in the coming working day. Business in progress, we will be online 24 hours for you.