Product Description

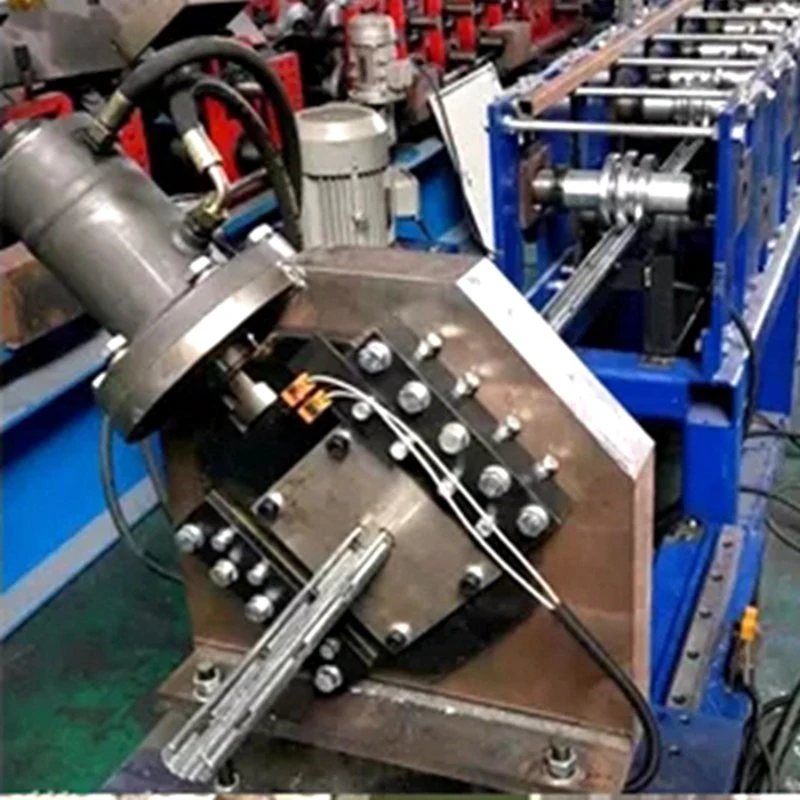

metal grape stake roll forming machine for customer Vineyard Metal Post making machine

Rolled Curved or Straight,Punched or Slotted.

Rolled Curved or Straight,Punched or Slotted.

| Uncoiler(manual/automatic) | Weight Capacity | 3T |

| Inner Diameter | 460-520mm | |

| Outside Diameter | 1400mm | |

| Coil width | Max 600mm | |

| Feeding | Pinch rollers | one pair, up and down |

| straightening device | Straightening rollers | up three, down four |

| Diameter of rollers | 75mm | |

| Roll Former | Frame type | single station |

| Forming Roller stand | about 14 Groups | |

| Shaft material | High grade 45# steel, | |

| Heated and quenched | ||

| Shaft diameter | 70mm | |

| Roller material | GCr15 | |

| Drive Type | By gear box | |

| Motor | 11KW reducer with | |

| requency control | ||

| Punching | Punching type | Hydraulic |

| Mould material | Cr12 | |

| Holes distance | Can be adjusted | |

| Cutting | Type | After-cutting, hydraulic |

| Hydraulic cutter | Material of mould | Cr12 |

| With quenching treatment | ||

| Cutting tolerance | 10M+/- 2.0 mm | |

| PLC cabinet | PLC | PANASONIC /Mitsubishi |

| Length Controller | Encoder | |

| Operation | Touch Screen | |

| Transducer | Mitsubishi | |

| Hydraulic station | Hydraulic station power | 11 KW |

| Hydraulic pressure | 15 Mpa | |

| Runout Table | Non-power type | 2 pcs |

| Material | Galvanized steel sheet | |

| Material Thick | 1.5-2.5mm | |

| Forming Speed | 8-12m/Min |

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) Please visit company and test machine if convenient.