Product Description

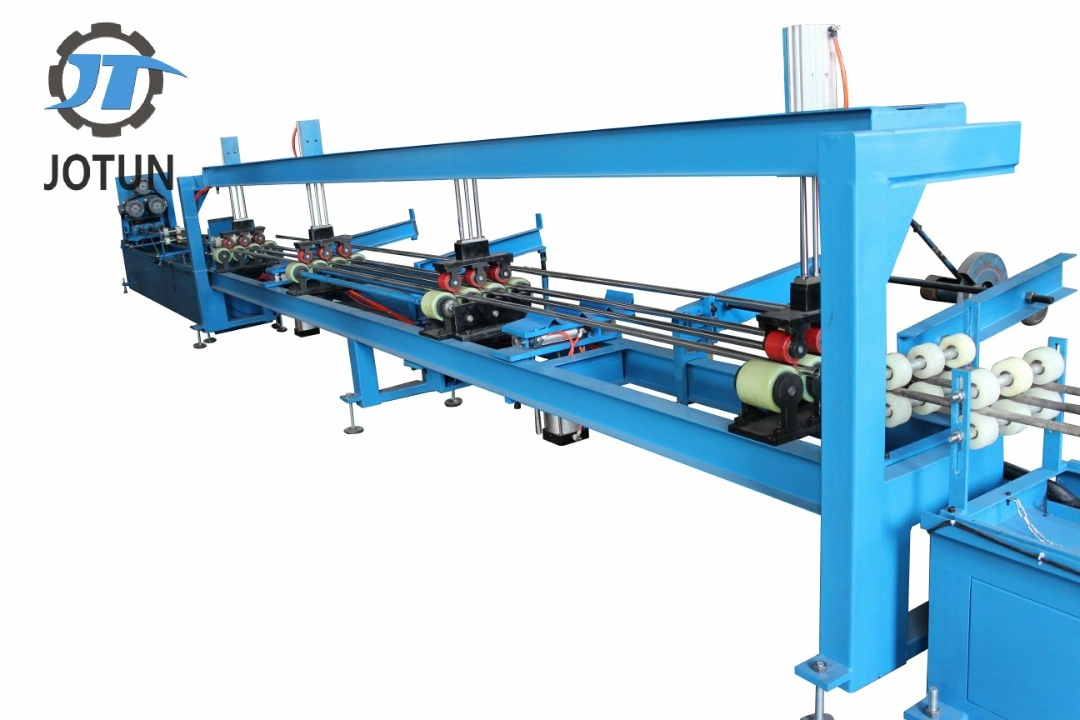

JT-Tube Inside Polishing Machine

The

machine adopts 4 cylinder clamp tubes, which are driven by the motor to rotate the polishing rod and the polishing head. The three

polishing heads on the left and right are simultaneously operated to polish the inner wall of the stainless steel pipe.This

machine only needs one operator to operate the machine. The machine can polish three 3 to 6 meters long stainless steel pipes at a

time, and can set different polishing speeds according to the different diameters of the pipes. The polished stainless steel pipe

is driven by four cylinders for automatic unloading.

machine adopts 4 cylinder clamp tubes, which are driven by the motor to rotate the polishing rod and the polishing head. The three

polishing heads on the left and right are simultaneously operated to polish the inner wall of the stainless steel pipe.This

machine only needs one operator to operate the machine. The machine can polish three 3 to 6 meters long stainless steel pipes at a

time, and can set different polishing speeds according to the different diameters of the pipes. The polished stainless steel pipe

is driven by four cylinders for automatic unloading.

Technical Parameter | ||

Outer Dimension | 15000*2000*1800 mm | |

Weight | 2500 kg | |

Input Power | 8 KW | |

Work Piece Size | Diameter | 19-219mm |

Length | 6000 mm | |

Thickness | 3 - 10 mm | |

Surface Roughness | Ra ≤ 0.28 μm (mirror finished) | |

1.Mainly used for polishing and drawing the surface of stainless steel pipe with drawing.

2. Continuous polishing process: After feeding, polishing (flap wheel, jute abrasive wheel, cloth wheel, wind cloth wheel), plus polishing wax, discharge and other technics.

3. As the stainless steel polishing machine polishing technology is mature, widely used in decoration.

4. Convenient operation, high quality, reasonable price, consistent with the quality of domestic and international market demands, making high-quality, high brightness of the tube.

2. Continuous polishing process: After feeding, polishing (flap wheel, jute abrasive wheel, cloth wheel, wind cloth wheel), plus polishing wax, discharge and other technics.

3. As the stainless steel polishing machine polishing technology is mature, widely used in decoration.

4. Convenient operation, high quality, reasonable price, consistent with the quality of domestic and international market demands, making high-quality, high brightness of the tube.

China Jotun Polishing Machine supply China professional

automatic grinding machine for Metal tank shell,dished end,flat sheet,round tube,welding seam treatment Equipment,main products are cylinder grinding machine, stainless steel tank shell polishing machine,dish head polishing machine, round tube polishing machine,welding seam grinding machine.

widely used for pharmaceutical industry,food,water purification,water supply,chemical,and new energy.Including elliptical dish,cone dish head,spherical shell ,butterfly shell,pharmaceutical stainless steel tank,pressure vessel,brewery,cylinder,cosmetic,sanitary,reaction kettle,fermentation?tank,sterilizer,disinfection cabinet,filter, and LNG etc.

Everyone in our team will do their best to serve you, solve your problems and achieve mutually beneficial cooperation.

automatic grinding machine for Metal tank shell,dished end,flat sheet,round tube,welding seam treatment Equipment,main products are cylinder grinding machine, stainless steel tank shell polishing machine,dish head polishing machine, round tube polishing machine,welding seam grinding machine.

widely used for pharmaceutical industry,food,water purification,water supply,chemical,and new energy.Including elliptical dish,cone dish head,spherical shell ,butterfly shell,pharmaceutical stainless steel tank,pressure vessel,brewery,cylinder,cosmetic,sanitary,reaction kettle,fermentation?tank,sterilizer,disinfection cabinet,filter, and LNG etc.

Everyone in our team will do their best to serve you, solve your problems and achieve mutually beneficial cooperation.