Basic Info.

Model NO.

1060 1050 1100

Surface Treatment

Polished

Alloy

Non-alloy

Samples

Available

Delivery Time

15-21 Days

Tolerance

+/-1%

Size

Customized

Processing

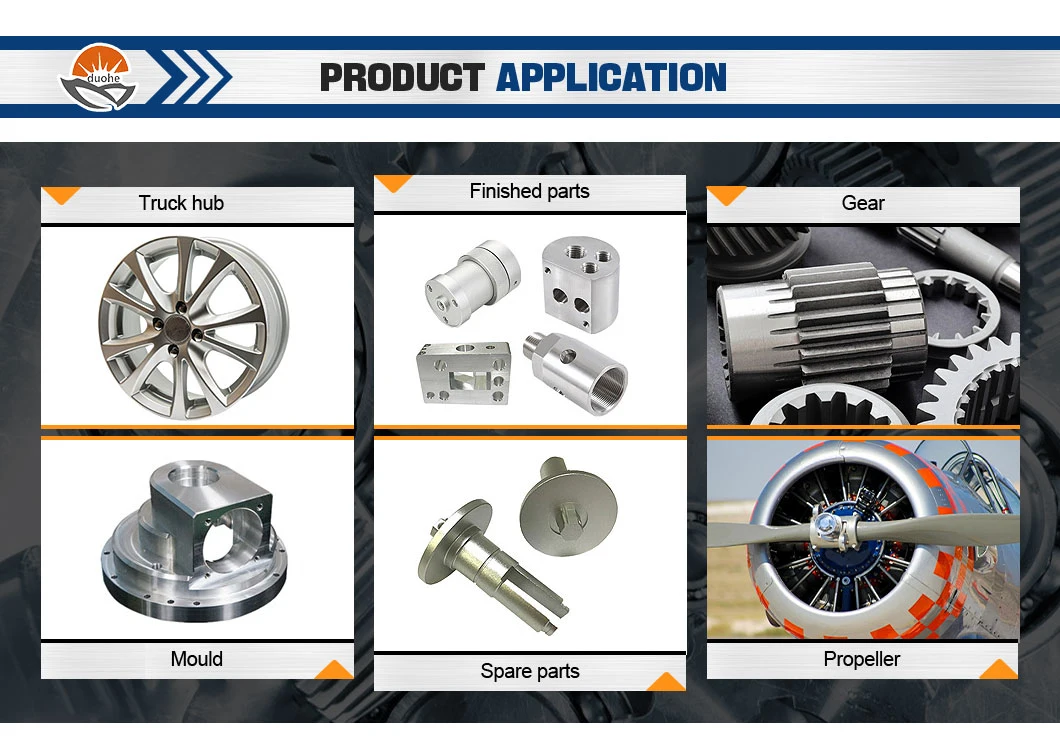

Bending, Decoiling, Welding, Punching, Cutting

Diameter

1-60mm

MOQ

1 Ton

Transport Package

Standard Seaworthy Export Packing

Specification

customized

Trademark

Duohe

Origin

Shandong, China

HS Code

721823

Production Capacity

100, 000 Tons Per Year

Product Description

https://dhstainless.en.made-in-china.com/product-group/NqhGsePACuUV/Aluminum-Bar-Rod-1.html

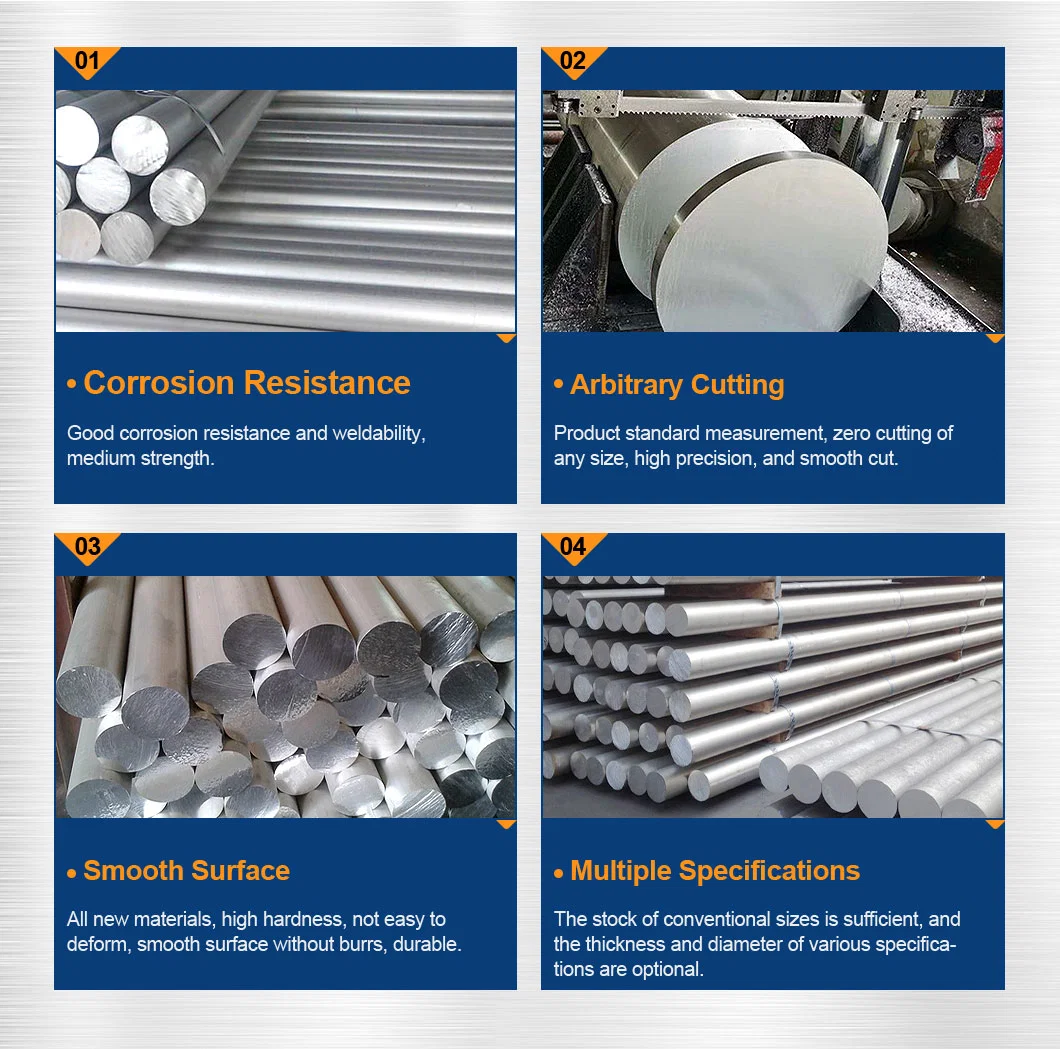

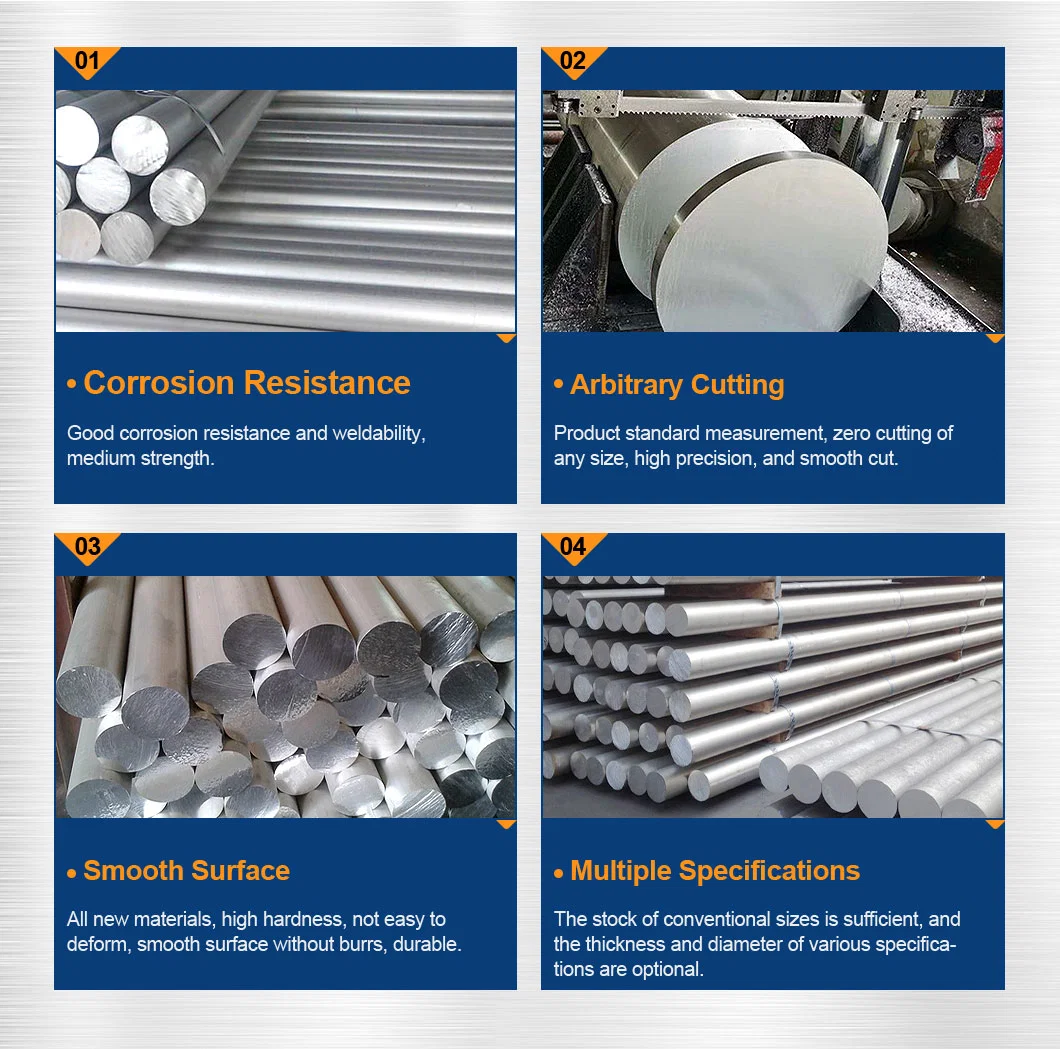

Aluminum rod is a kind of aluminum product. The melting and casting of aluminum rod includes melting, purification, impurity removal, degassing, slag removal and casting process.

Aluminum (Al) is a light metal whose compounds are widely distributed in nature.

According to the different metal elements contained in aluminum rods, aluminum rods can be roughly divided into 8 categories: 1000 series aluminum rods/2000 series aluminum rods/3000 series aluminum rods/4000 series aluminum rods/5000 series aluminum rods/6000 series aluminum rods/ 7000 series aluminum rod/8000 series aluminum rod.

Different series of copper rods correspond to different applications, such as: food, chemical and brewing industry, chemical product containers, etc.

The main process of casting is:

(1) Ingredients: According to the specific alloy grades that need to be produced, calculate the addition amount of various alloy components, and reasonably match various raw materials.

(2) Smelting: The prepared raw materials are put into the melting furnace for melting according to the process requirements, and the impurities and gases in the melt are effectively removed by means of degassing and slag removal and refining.

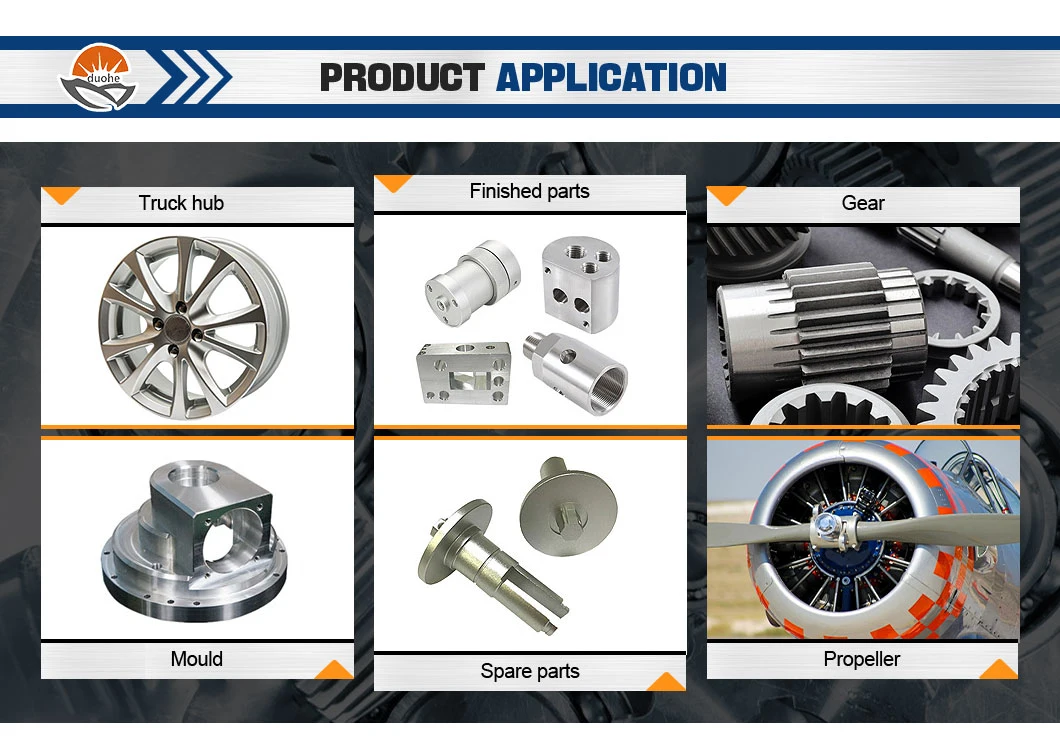

(3) Casting: Under certain casting process conditions, the smelted aluminum liquid is cooled and cast into round casting rods of various specifications through the deep well casting system.

Aluminum rod is a kind of aluminum product. The melting and casting of aluminum rod includes melting, purification, impurity removal, degassing, slag removal and casting process.

Aluminum (Al) is a light metal whose compounds are widely distributed in nature.

According to the different metal elements contained in aluminum rods, aluminum rods can be roughly divided into 8 categories: 1000 series aluminum rods/2000 series aluminum rods/3000 series aluminum rods/4000 series aluminum rods/5000 series aluminum rods/6000 series aluminum rods/ 7000 series aluminum rod/8000 series aluminum rod.

Different series of copper rods correspond to different applications, such as: food, chemical and brewing industry, chemical product containers, etc.

The main process of casting is:

(1) Ingredients: According to the specific alloy grades that need to be produced, calculate the addition amount of various alloy components, and reasonably match various raw materials.

(2) Smelting: The prepared raw materials are put into the melting furnace for melting according to the process requirements, and the impurities and gases in the melt are effectively removed by means of degassing and slag removal and refining.

(3) Casting: Under certain casting process conditions, the smelted aluminum liquid is cooled and cast into round casting rods of various specifications through the deep well casting system.

| Product Name | Aluminum Round Bar |

| Material | 1060,1200,1100,2024,2124,3003,3004,3A12,5052,5652,5154,5254,5454,5083,5754,5086,5056,5456,5A02,6061,6062,6063,7075,8011,etc. |

| OD | 21.3mm-508mm |

| Length | as required |

| Diameter | 1-60mm or as required |

| Surface | mill, bright, polished, hair line, brush,sand blast, checkered,embossed, etching,etc |

| Price Term | Ex-work, FOB, CFR, CIF, etc. |

| Application | construction,decoration,hardware,electric appliances,machinery and other industrial and civil purposes,computer casting,telecommunication,equipment,lamp shade,air conditioner,cosmetics cover and so on. |