Basic Info.

Model NO.

1.3247/M42/SKH59/W2Mo9Cr4VCo8

Delivery condition

hot rolled black surface

Quality Assurance

100% UT passed

Delivery Time

7days

Condition

stock

Transport Package

standard/customized

Specification

standard/customized

Trademark

customized

Origin

China

HS Code

7228300000

Production Capacity

1000t/Month

Product Description

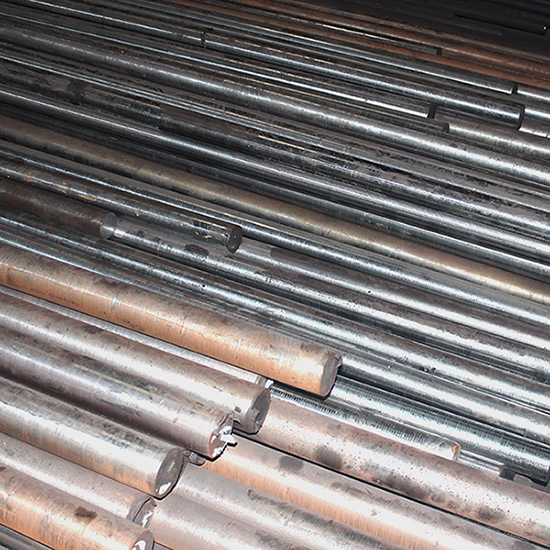

High Speed Tool Steel AISI M42 Hot Rolled Black Surface Round Steel

Product Introduction

M42 super high speed steel is a premium cobalt high speed steel with a chemical composition designed for high hardness and superior hot hardness. These properties make the steel an excellent choice for machining high-strength and pre-hardened steels, high-hardness alloys, and the difficult-to-machine, nonferrous super alloys used in the aerospace, oil, and power generation industries.

M42 exhibits excellent wear resistance by virtue of high heat-treated hardness (68 to 70 HRC), and the high cobalt content imparts the hot hardness. As such, the cutting

edges on tools made from M42 super high speed steel stay sharp and hard in heavy-duty and high-production cutting applications.

Chemical Composition

Features

Wear and abrasive resistance

• Can maintain cutting edge until 600c

• Easy to harden and can do vacuum hardening

• Provide high hardness after hardening (64-66 HRC)

• Resistance to annealing at high temperature

• High tensile as compare to AISID2

• High performance in cutting application. Can be applied to cut any kind of materials.

• High resistance to carbon losing at its surface

• Welding abiity

• Ablity to do hard surface by nitriding

• Ability to coating surface with PVD method.

Applications

Twist drills, taps, milling cutters, reamers, broaches, saws, knives, and thread rolling dies.

Quality Inspection

Loading

Product Introduction

M42 super high speed steel is a premium cobalt high speed steel with a chemical composition designed for high hardness and superior hot hardness. These properties make the steel an excellent choice for machining high-strength and pre-hardened steels, high-hardness alloys, and the difficult-to-machine, nonferrous super alloys used in the aerospace, oil, and power generation industries.

M42 exhibits excellent wear resistance by virtue of high heat-treated hardness (68 to 70 HRC), and the high cobalt content imparts the hot hardness. As such, the cutting

edges on tools made from M42 super high speed steel stay sharp and hard in heavy-duty and high-production cutting applications.

Chemical Composition

| C | Si | Cr | W | Mo | V | Co |

| 1.08 | 0.45 | 3.85 | 1.50 | 9.50 | 1.20 | 8.00 |

PHYSICAL PROPERTIES

- Density: 0.282 lb/in3 (7806 kg/m3)

- Specific Gravity: 7.81

- Modulus of Elasticity: 30 x 106 psi (207 GPa)

- Machinability: 35-40% of a 1% carbon steel

Features

Wear and abrasive resistance

• Can maintain cutting edge until 600c

• Easy to harden and can do vacuum hardening

• Provide high hardness after hardening (64-66 HRC)

• Resistance to annealing at high temperature

• High tensile as compare to AISID2

• High performance in cutting application. Can be applied to cut any kind of materials.

• High resistance to carbon losing at its surface

• Welding abiity

• Ablity to do hard surface by nitriding

• Ability to coating surface with PVD method.

Applications

Twist drills, taps, milling cutters, reamers, broaches, saws, knives, and thread rolling dies.

Quality Inspection

Loading