Basic Info.

Model NO.

1530T

Structure Type

Desktop

Laser Classification

Free Electron Laser

Laser Technology

Laser Control Fault Cutting

Avliable Cutting Material

Aluminum/Steel/Iron

Certification

CE

Laser Source Brand

Raycus

Moter

Servo

Lathe

The Lathe Bed Is Made of Cast Iron

Laser Head

Jia Qiang

Application Material

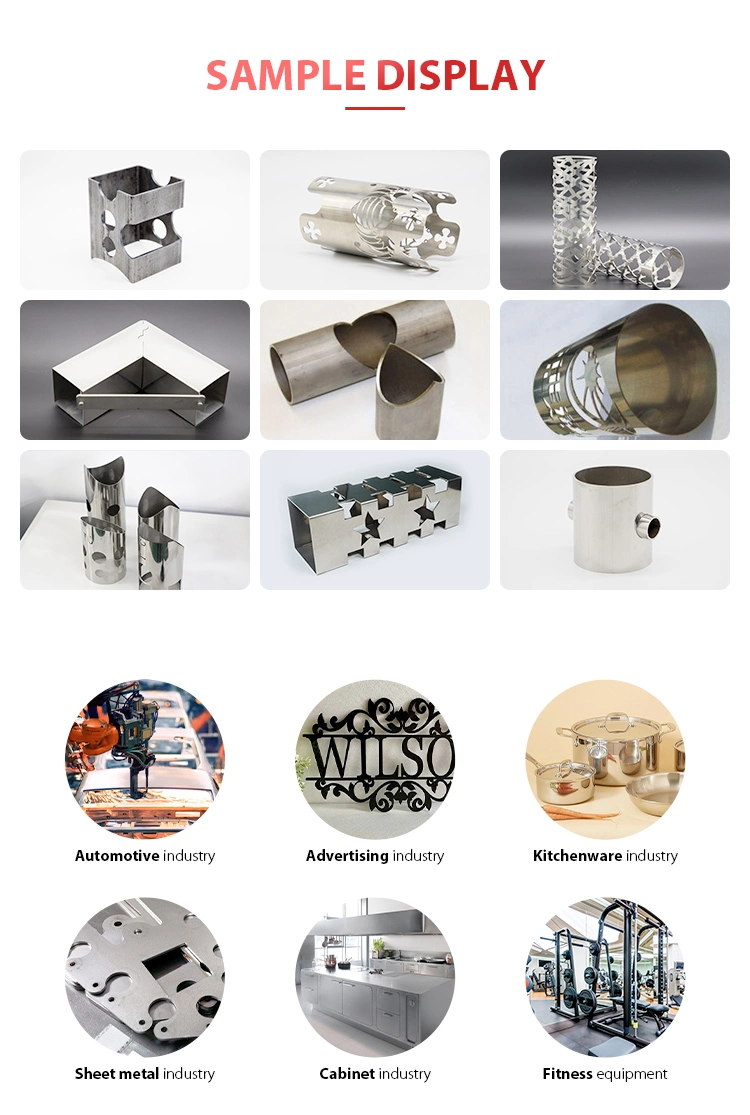

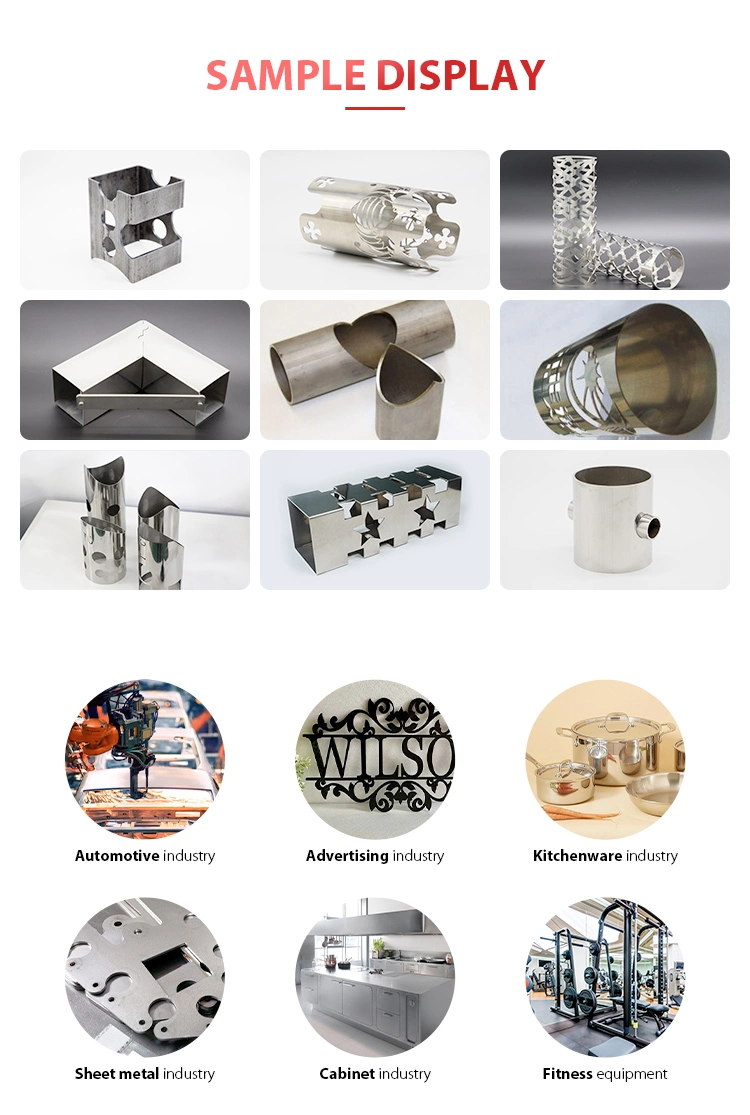

Metal Sheet Iron/CS/Ss/Aluminum/Copper

Key Selling Points

Multifuctional

Motor Speed

3000 Rpm

Marketing Type

Ordinary Product

Cutting Speed

0-60m/Min

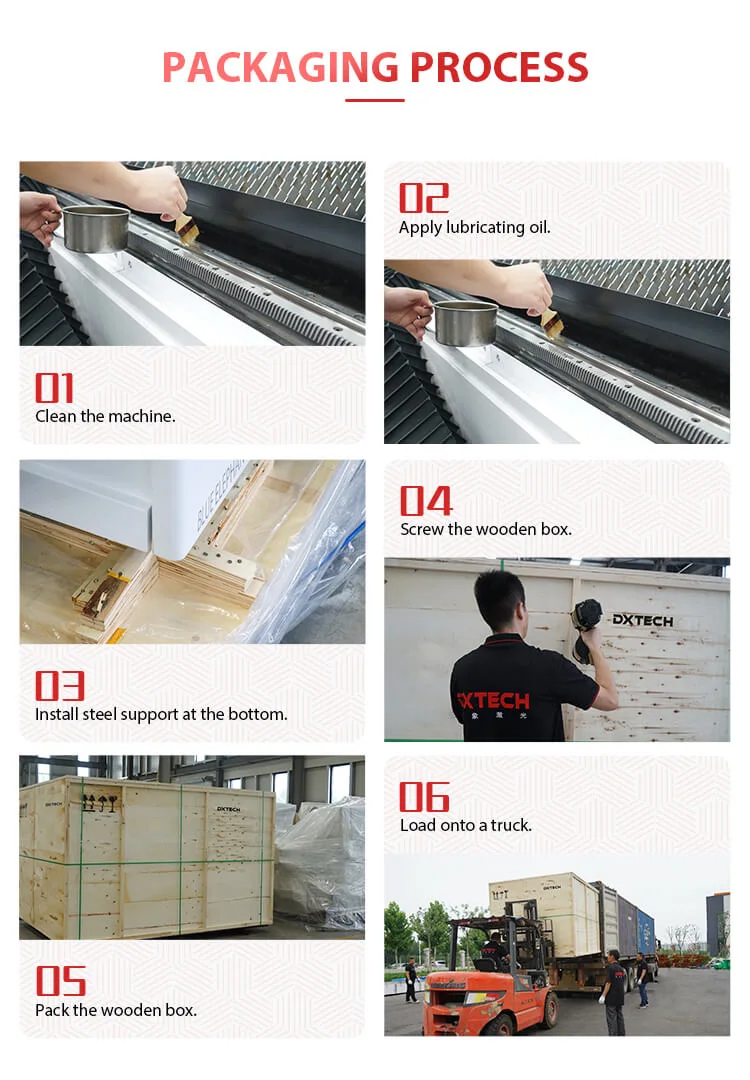

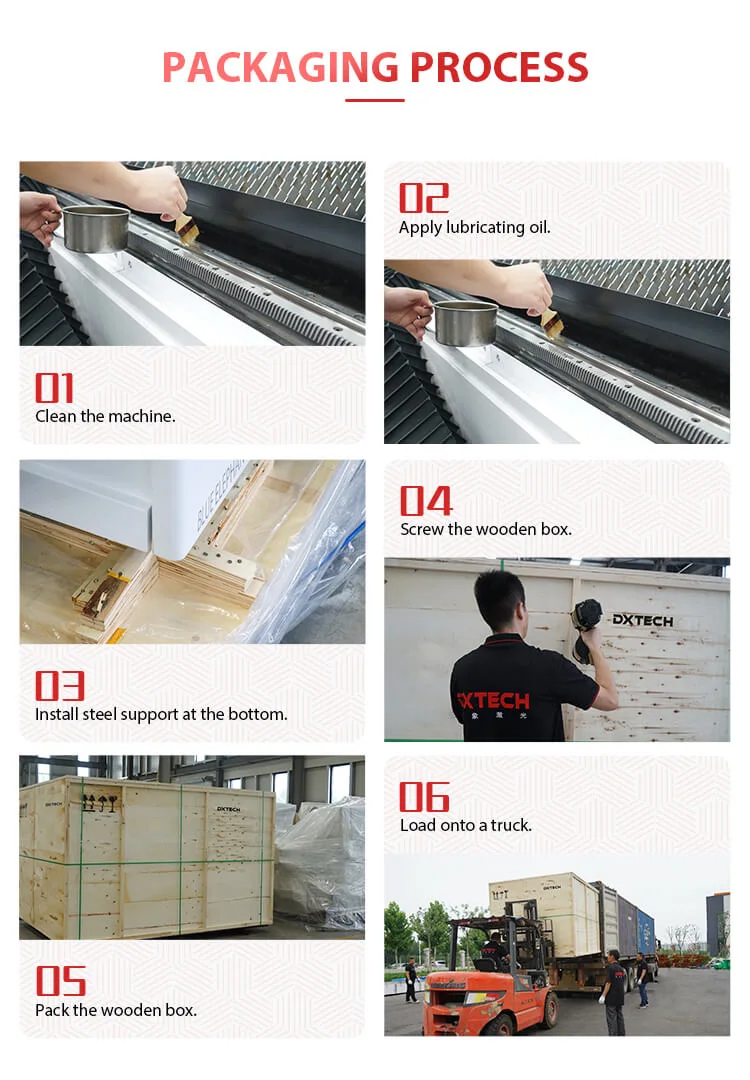

Transport Package

Wooden Box

Specification

1500mm*3000mm

Trademark

dxtech

Origin

Shandong, China

HS Code

8456110090

Production Capacity

30sets/Month

Product Description

Product Description

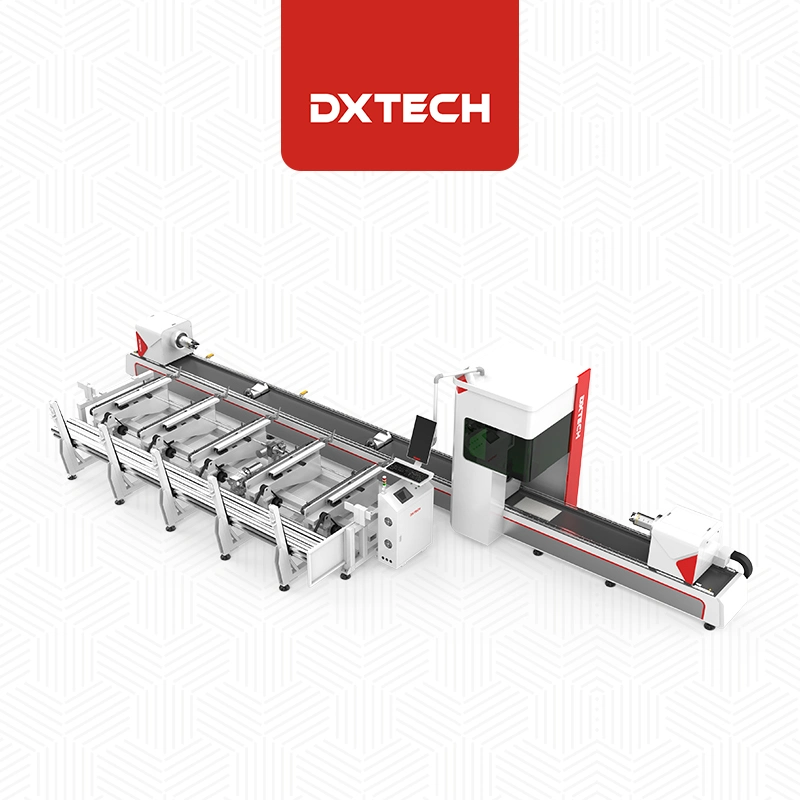

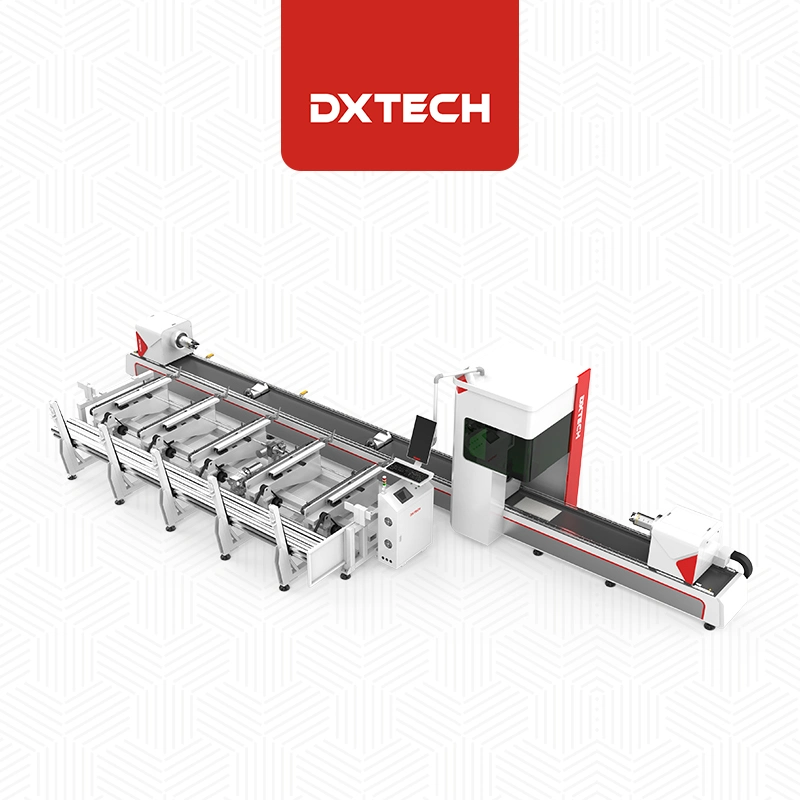

The professional three chuck metal tube cutting machine with automatic feeding is specially designed for high-volume cutting of pipes, and it is more efficient than ordinary laser systems in cutting pipes and tubular metals. Tubes and rectangular tubes can be fed fully automatically without manual operation. The deformed tube can realize manual semi-automatic feeding. It is suitable for cutting round pipes, square pipes, rectangular pipes, waist pipes, angle steel, channel steel, I-beam and other special-shaped metal pipes. Fast corner response greatly improves cutting efficiency. After the workpiece is cut, it can be automatically unloaded by area.

Features

Product Parameters

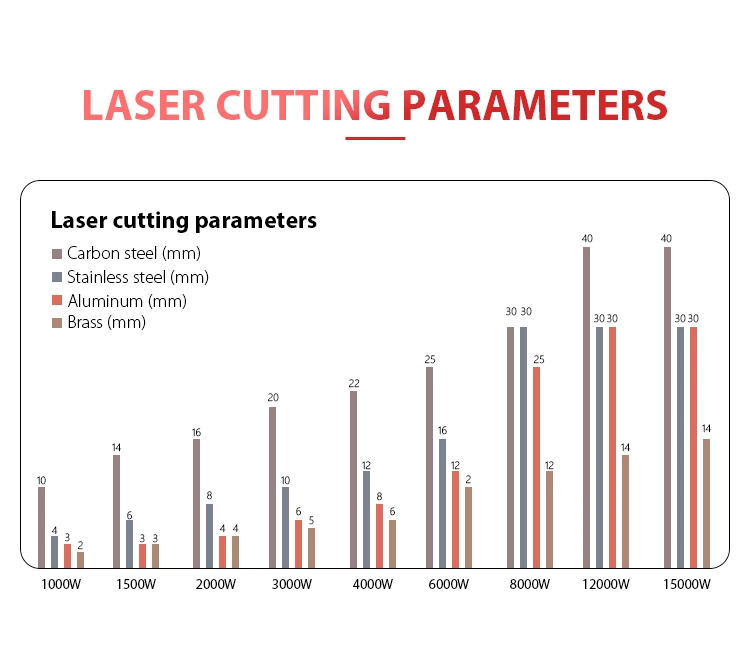

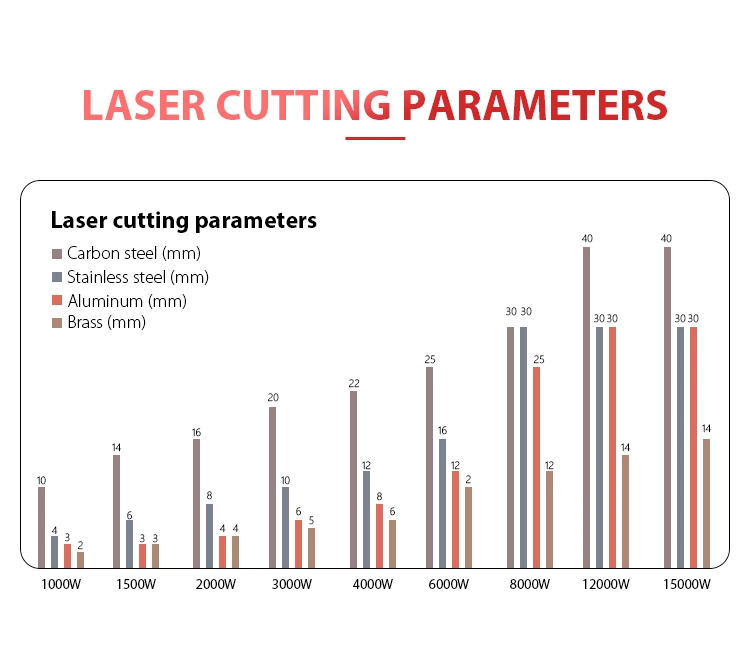

Cutting materials and thickness

The professional three chuck metal tube cutting machine with automatic feeding is specially designed for high-volume cutting of pipes, and it is more efficient than ordinary laser systems in cutting pipes and tubular metals. Tubes and rectangular tubes can be fed fully automatically without manual operation. The deformed tube can realize manual semi-automatic feeding. It is suitable for cutting round pipes, square pipes, rectangular pipes, waist pipes, angle steel, channel steel, I-beam and other special-shaped metal pipes. Fast corner response greatly improves cutting efficiency. After the workpiece is cut, it can be automatically unloaded by area.

1. Sheet metal welding bed

Strong and stable performance, strong anti-vibration ability, easily guarantee longer and higher cutting accuracy.

2. Patented pneumatic chuck, superior to electric chuck.

The performance is very stable, the diameter supports 10mm-350mm pipes, and it can clamp pipes of different shapes

3. Automatic feeding, automatic loading, fast cutting speed, good cutting quality, high precision, perfect after-sales service

Product Parameters

| Model | DXTECH-T6160/T9160 | DXTECH-T6220/T9220 |

| Max. tube length | 6.5m/9.2m | 6.5m/9.2m |

| Tube shape | Round/square/rectangular | Round/square/rectangular |

| Max. tube weight | 100kg 16kg/m | 200kg 30kg/m |

| Positioning accuracy | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm |

| Chuck | Two pneumatic chucks | Two pneumatic chucks |

| Max. chuck rotating speed | 130r/min | 130r/min |

| Laser power | 1kW - 4kW | 1kW - 4kW |

| Laser | Multiple options | Multiple options |

| Servo motor and driver | YASKAWA/FUJI | YASKAWA/FUJI |

| Reducer | Shimpo | Shimpo |

Cutting materials and thickness

| Carbon steel | 0.4-6mm | 0.4-10mm | 0.4-12mm | 0.4-14mm | 0.4-16mm | 0.4-20mm |

| Stainless steel | 0.4-3mm | 0.4-4mm | 0.4-5mm | 0.4-6mm | 0.4-8mm | 0.4-10mm |

| Aluminum | 0.4-2mm | 0.4-3mm | 0.4-3mm | 0.4-4mm | 0.4-6mm | 0.4-8mm |

| Brass | 0.4-3mm | 0.4-3mm | 0.4-3mm | 0.4-8mm | ||

| Laser power | 500w | 750w | 1000w | 1500w | 2000w | 3000w |