- Overview

- Detailed Photos

- Company Profile

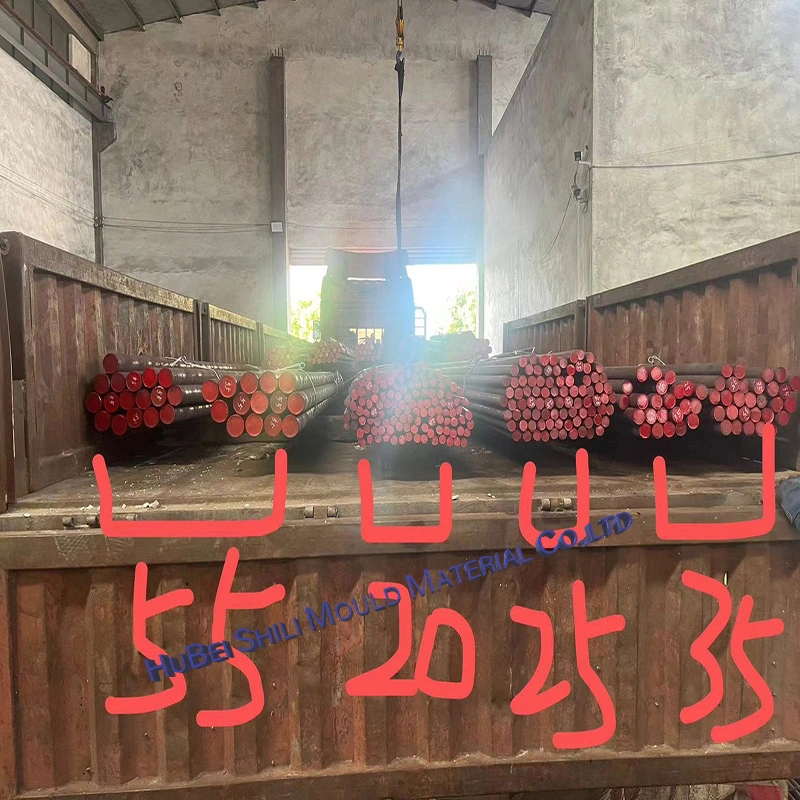

- Loading Pictures

- FAQ

Basic Info.

Product Description

| HUBEI SHILI MOULD MATERIAL CO., LTD | |||||||||||||||

| Yang Ye Zhen Industrial Park,Ezhou City,Hubei Province,China | |||||||||||||||

| Specification No. SL-CrWMn/1.2419-Rev1 | |||||||||||||||

| Steel grade | Standard | Dia./Thickness | Width | Lengths | Tolerance | ||||||||||

| CrWMn | GBT 1299-2014 | 8-75 mm | 310-610 mm | 2000-5800 mm | Thickness 0/+2 mm | ||||||||||

| 1.2419 | DIN ISO 4957 | Width 0/+10 mm | |||||||||||||

| Manufacturing conditions | Heat treatment | Other regulations | |||||||||||||

| Hot rolled alloy steel flat bars | Annealed | EF+ LF+VD | |||||||||||||

| Delivery in black/Sand Blast/ Machining | Reduction ratio ≥ 3 | ||||||||||||||

| Top & Bottom Ends of bars sawn | Fully formed structure | ||||||||||||||

| Permissible curvature of not more than | 100% mismatch checked | ||||||||||||||

| 7.6mm over the whole length of products | |||||||||||||||

| Chemical composition - heat analysis (%) | |||||||||||||||

| C | Si | Mn | P | S | Cr | W | |||||||||

| min. | 0.95 | 0.10 | 0.80 | 0.90 | 1.20 | ||||||||||

| max. | 1.05 | 0.40 | 1.10 | 0.030 | 0.030 | 1.20 | 1.60 | ||||||||

| Surface hardness | |||||||||||||||

| Max 210 HB | |||||||||||||||

| Mechanical properties | |||||||||||||||

| Tensile test | Unit | Remarks | |||||||||||||

| Rm | - | N/mm2 | |||||||||||||

| Re | - | N/mm2 | |||||||||||||

| A | - | % | |||||||||||||

| Z | - | % | |||||||||||||

| Impact test | |||||||||||||||

| ISO-V | - | ||||||||||||||

| Metallography - microstructure | |||||||||||||||

| Structure | - | ||||||||||||||

| Grain size | 6-8 acc. to ASTM | ||||||||||||||

| Shipping Mark | Head of bars stamped with grade,heat No.,weight,size | ||||||||||||||

| US test | acc. to SEP 1921 D/d/3 to be confirmed in MTC | ||||||||||||||

| Surface test | 100% visually checked, clean surface free from defects. | ||||||||||||||

| Quality Certificate | EN 10204/3.1 with full chemical composition | ||||||||||||||

| Other requirements : -Hardness in HB,Reduction ratio, UT test,Non-metallic inclusions , grain size, standard, | |||||||||||||||

| free from radioactivity checked to be confirmed in MTC. | |||||||||||||||

We ,Hubei Shili mill has independently researched and developed a production line with a dia850 rolling machine. Our melting method is EF+LF+VD or EF+LF+VD+ESR , equipped with 8ton +15ton +20ton melting furnaces; Our Electric annealing furnace can ensure diffusion annealing for the whole steel . Consequently, we acquire two patents for innovation and the monthly capacity is 5000tons flat bars and round

We manufactures a wide range of products including cold/hot work tool steel, Grades like as 1.2379/D2/SKD11,1.2601/D5/X12M, 1.2080/D3/X12/,1.2363/A2,1.2510/O1,1.2842/O2,1.2550/S1,1.2436/S6,1.2767/6F7,1.2419/O7,1.2365/H10,1.2343/H11,1.2344/H13,9Cr15M/440C,GCr15/52100 etc.

Over years, we supply steel materials and offer variety steel solutions for worldwide distributors, retailers, manufacturers and the likes. We experience on different tool steel machinery based on customer demand and preference.

Furthermore, we dynamic in our procedure and technique which is flexible enough to incorporate the changing demands in the international market. Our services are tailored specifically to meet the needs of our esteemed customers. While many things have changed in the steel industry, our commitment to quality and service remains the same, with our dedication to total customer satisfaction. We continually work to expand our outreach and business interests, to the delight of our ever increasing customer base.

Q1 : Are you a trading company or manufacturer?

We are a real manufacturer , specializing in tool steels and special steels for over 15 years. Our factory is located in huangshi , hubei , which is the biggest tool steel production base in China . And we are also the top1 rolling mill to roll plates in Hubei province.

Q2 : What's your main production equipment ?

Our melting method is EF+LF+VD , equip 8ton +20ton +20ton melting furnaces;

We are equipped with #850 auto-rolling machine to roll our flats , the monthly capacity is 5000ton ;

We are also equipped 6 electric heat treatment furnaces doing annealing + 8 ends sawn doing ends cutting +2 straighten machine ;

We are equipped with independent testing lab to ensure chemical composition, UT and hardness qualified.

Q3 : What's your main tool steel grades your company offers ?

All kinds of hot work tool steels and cold work tool steels , some bearing steels and placstic steels like as 1.2379/D2,1.2601/D5/Cr12MoV,

1.2080/D3/Cr12,1.2631/DC53,1.2363/A2,1.2510/O1,1.2842/O2,1.2550/S1,1.2357/S7,1.2436/D6,1.2419/O7, 1.2343/H11, 1.2344/H13,1.2367,

1.2714/L6, 9Cr18Mo,GCr15/52100 etc, in round bar, flat bar, and plate, And provide Customized services to you.

Q4 : What is your MOQ?

Our MOQ for each size is 500kgs ; MOQ for each order is around 25-27.5Tons(one container), customer can mix different grades and sizes in one container .

Q5 : How to ensure good quality ?

Over years our factory developed very mature acknowledge and unique patent technology to roll plates and rounds , especially very thin flats ,

to ensure qualified inner and surface quality . What's more , we have the very professional and experienced inspectors to do testing for each flat and each round before delivery . We can provide MTC for each steel .

Q6 : Can we visit your company and factory?

Yes, warmly welcome! You can come to China and visit us at any time .