Product Description

Brass bars are rods made of an alloy of copper and zinc. They get their name from their yellow color.Copper content of 56%~68% of brass, its melting point of 934~967 degrees.The mechanical and wear resistance of brass are very good, can be used in the manufacture of precision instruments, ship parts, gun casings and so on.

Different amounts of zinc can have different colors, such as red and yellow for zinc content of 18%-20%, and brown-yellow for zinc content of 20%-30%.In addition, brass sounds unique, so the eastern gongs, cymbals, bells, horns and other instruments, as well as western brass instruments are made of brass.

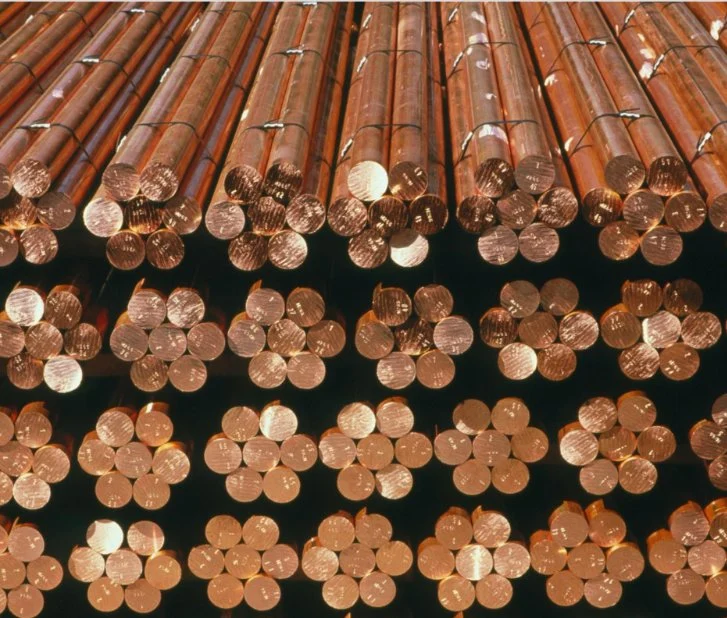

Copper Round Bar, is widely known for its electrical applications whereas it has very high electrical and thermal conductivity. In addition, copper round bars are used in artistic works along with architectural applications because of its corrosion resistance and familiar green patina appearance acheived after being exposed to the elements. Copper rounds have excellent hot or cold workability and is very ductile when heated.

| Material Grade | C10100,C11000,C12200,C21000,C22000,C23000,C24000,C26000,C27000,C26800,C27200,C27400, C28000,C36500,C33000,C35300,C35600,C36000,C38500,C44300,C46400,C52100,C54400,C62300, C65500,C67500,C67600,C86300,C90700,C93200,C95400 etc. |

| Standard | GB,JIS,ASTM,BS,DIN,API,... |

| Shape | round, flat, square, rectangle, hexagon, angle |

| OD | 1)Round bar: 1 mm -800 mm or as per customer's request, normal: 10mm 20mm 30mm 50mm 80mm 100mm 200mm 500mm 2)Square bar: 1mm*1mm -- 800mm*800mm 3)Hexagonal bar: 2mm -- 100mm 4)Flat bar: Thickness: 2mm~100mm, Width: 10mm~500mm |

| Length | 2m,3m,5.8m,6m,12m or as per customer's request |

| Technique | Cold Rolled; Hot Rolled |

| Surface | Mill finish, polished, anodizing, brushing, sand blasting, powder coating, etc |

| Hardness | 1/16 hard, 1/8 hard, 3/8 hard, 1/4 hard, 1/2hard, full hard, soft, etc |

| Applicaiton | Petroleum, electronics, chemical industry, medicine, light textile, food, machinery, construction, nuclear power, aerospace,military and other industries |

| Trade Terms | EXW,FOB,CIF CFR |

| Loading Port | Shanghai port, Tianjin port, Qindao port |

| Payment terms | 1) 30% deposit by T/T, the balance against copy of B/L by T/T. |

| 2) 30% deposit by T/T, the balance by L/C at sight. | |

| 3) 100% L/C at sight. | |

| MOQ | 500kgs |

| Packing Detail | Bundled,wooden box for export standard package (Standard export package or as required) |

| Delivery time | 1.Usually,within10-20days after receiving deposit or LC. 2.According to the order quantity |

| Samples | Free samples are provided but the freight is borne by the buyer |

Copper Material Grade

1)Pure Copper:T1,T2,C11000,C1100

2)Silver Copper:C11300,C11400,C11500,C11600,C11700,TAg0.1,

3)Brass: H96,H90,H80,H70,H62, C21000,C22000,C24000,C26000,C27400,etc

4)Tin Bronze:C90300,C90500,C90700,C91000,C91100,C91300,C92200,C92300,C92500,

C92700,C93200,C93800,

QSn4-0.3,QSn8-0.3,QSn6.5-0.1,QSn6.5-0.4,C51100,C51000,C51900,C52100,etc

5)Zinc White Copper:BZn18-18, BZn18-26, BZn15-20, BZn18-10,C75200,C77000,etc

6)Nickel White Copper:C72200,C72500,C70400,C70600,C71000,C71500, BFe5-1.5-0.5,BFe10-1-1,BFe30-1-1, B0.6,B19,B25,B30,etc

7) Oxggen Free Copper: TU1,TU2,C10100, C10200, C10300,

8) Beryllium bronze:C17000,C17200,C17150,C17300, QBe2,QBe0.4-1.8,etc

9) Aluminum bronze: C61000,C61300,C61400,C61900,C62300,C62400,C63200,C95200,C95400,C95200,etc

10)Aluminum Bronze Copper:QAl5,QAl9-2,QAl7,QAl9-4,C60600,C60800,C61000,C61300,C61400,C61900,C62300,C62400,C63200,etc

11)NCu40-2-1

12)other

Table 1. chemical composition of Copper Bar

| Chemical Requirements | ||||||||||

| CU+AG (%) | SN (%) | ZN (%) | PB (%) | NI (%) | FE (%) | SB (%) | S (%) | AS (%) | BI (%) | O (%) |

| ≥99.90 | ≤0.002 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.002 | ≤0.005 | ≤0.002 | ≤0.001 | ≤0.06 |

| Alloy | Chemical Composition | ||||

| QB | JIS /ASTM | Cu | P | O | Other |

| T2 | JIS C1100 | 99.9 | 0.015-0.040 | - | balance |

| TU | ASTM C10300 | 99.95 | 0.001-0.005 | - | balance |

| TP1 | JIS C1220 | 99.9 | 0.004-0.012 | - | balance |

Table 2. Typical mechanical properties for Copper Bar

| Grade(China) | Grade(Japan) | Temper | Vickers Hardness (HV) | Tensile strength(Mpa) | Elongation(%) |

| T2/T3/TP1/TP2 | C11000/C1201 | M | - | ≥290 | ≥40 |

| C1220.etc. | Y4 | 75-125 | 325~410 | ≥35 | |

| Y2 | 85-145 | 340~460 | ≥25 | ||

| Y | 105-175 | 390~530 | ≥13 | ||

| T | - | ≥490 | - |

Petroleum, electronics, chemical industry, medicine, light textile, food, machinery, construction, nuclear power,

Petroleum, electronics, chemical industry, medicine, light textile, food, machinery, construction, nuclear power,aerospace,military and other industries

Wuxi Jianbanghaoda Steel Co., Ltd. is a sophisticated manufacturer of steel products. It's located in Wuxi, which is the biggest production base and distribution center of steel products in China , it's also near to Shanghai. We have many faithful clients in Europe, South America, Mid-East, Asia and etc. We have a wide range of steel products, such as stainless steel, carbon steel, alloy steel and etc. The annual export volume is about 1000,000 tons. We promised almost all inquiry will be dealed with within 3 hours. "Punctuality, Integrity, Humanization service" has always been the development principle that strictly adhered by our company and all stuff all the time.

Wuxi Jianbanghaoda Steel Co., Ltd. is a sophisticated manufacturer of steel products. It's located in Wuxi, which is the biggest production base and distribution center of steel products in China , it's also near to Shanghai. We have many faithful clients in Europe, South America, Mid-East, Asia and etc. We have a wide range of steel products, such as stainless steel, carbon steel, alloy steel and etc. The annual export volume is about 1000,000 tons. We promised almost all inquiry will be dealed with within 3 hours. "Punctuality, Integrity, Humanization service" has always been the development principle that strictly adhered by our company and all stuff all the time. At present, we have five finishing rolling production lines and two hot rolling production lines . Further more advanced automatic width control system (AWC), automatic thickness control system (AGC), bending roll system, work roll channeling roll system and other effective measures are adopted to guarantee product quality. Well-equipped production lines and advanced control systems work together to make sure all the stainless steel products we made are in line with the national standards.

OUR SERVICE:

OUR SERVICE:1.Provide free sample.

2.We have full stock and can deliver within short time.

3.OEM and ODM order are accepted, Any kind of logo printing or design are available.

4.We offer you the different types of product.

5.Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

6.All of our products are produced by our professional workman and we have our high-work-effect foreign trade team, you can

totally believe our service.

After you choose:

1. We will count cheapest shipping cost and send it to your email.

2. Start production immediately after receiving the advance payment.

3.About 10-15 working days to complete the production, and then the customer