Product Description

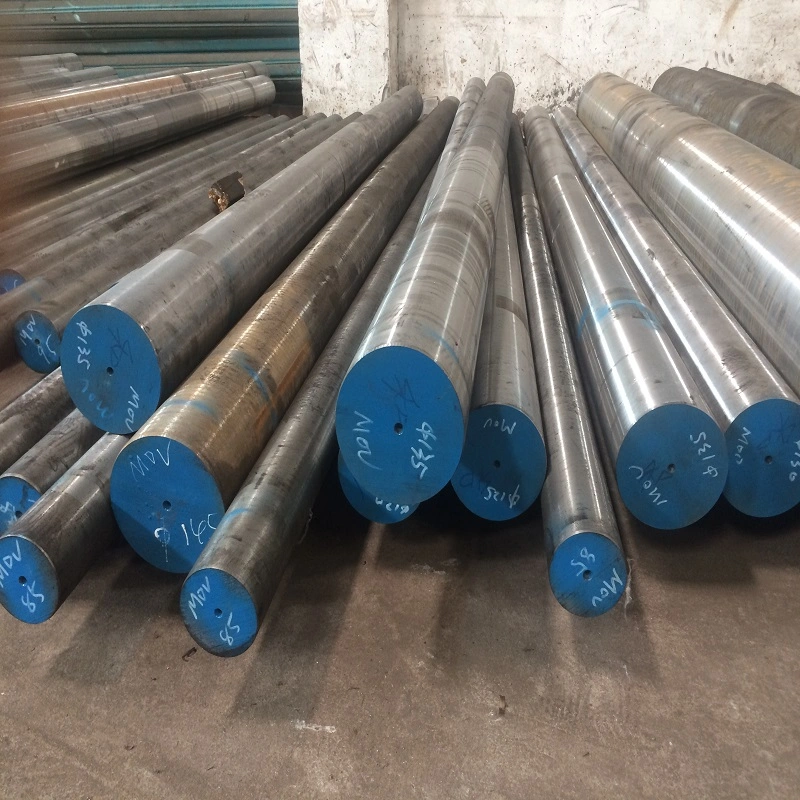

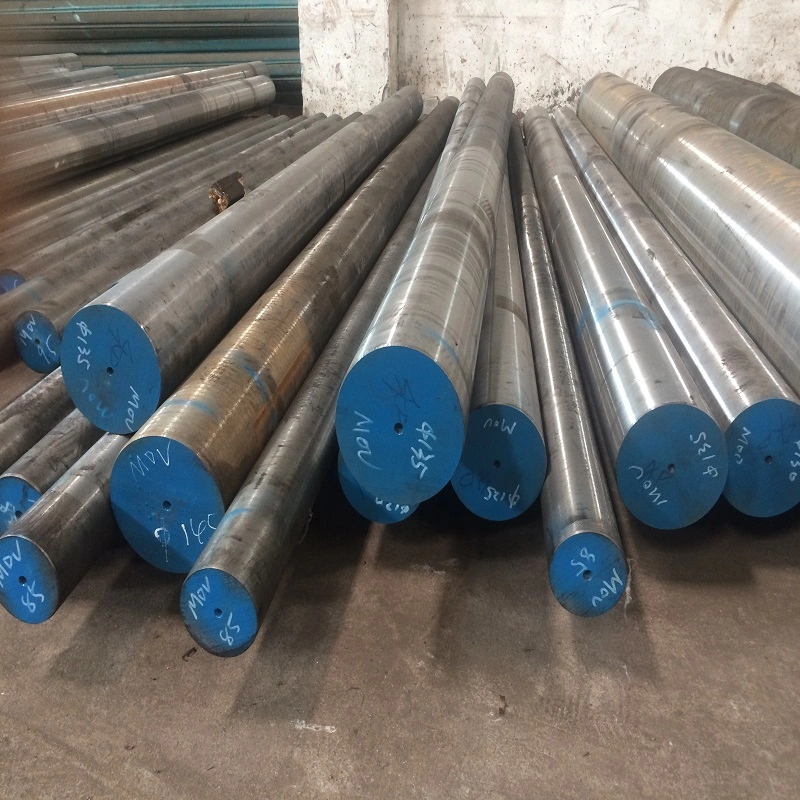

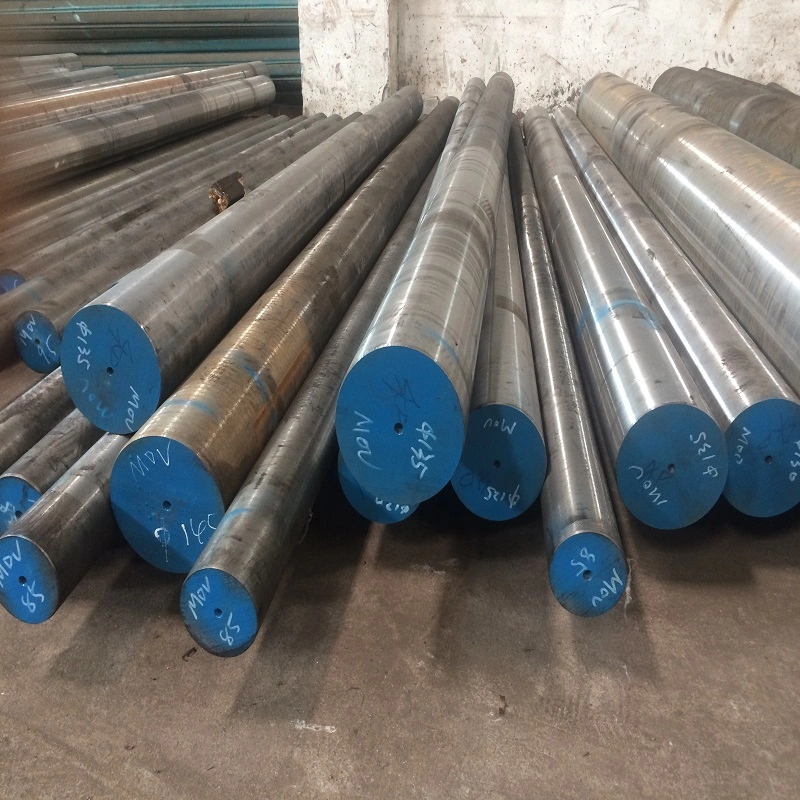

D2 SKD11 1.2379 Cr12MOV Black/Peeled/Turning Round Bar

D2 steel is a high wear resistant micro deformation cold working die steel, belonging to air hardening tool steel. With high quality fraction of carbon and high chronic, the hardness can up to 60HRC after heat treatment, but malleability,toughness,rust resistance is not good and the surface of the steel is also difficult to be polished.

With the development of cold stamping products moving towards high accuracy,high efficiency, varieties, we require the mould steel should has good wear resistance and high toughness.

Compared with Cr12MoV steel, this D2 die steel adds Mo,V compositions,changed the steel cast structure, improved the morphology of ledeburite , toughness and wear resistance are better than Cr12MoV steel, improved the service life as well.Because of the yield point and plastic deformation resistance is higher than Cr12MoV steel, so that forging performance and hot molding properties are a little weak than Cr12MoV steel.

Features

Chemical Composition

Heat Treatment

Applications

Blanking Mold

Roller

bending mold

Cutting tool&knife

Stock Size

Packing & delivery

Antirust oil, Pearl Film, Spacer, Kraft Paper, Wooden Case, Wooden Frame, Ect.

Accept Customized Packing.

Services

Sawing-to-size- Flate/ Round (Vertical Cutting/ Horizontal Cutting machine)

Machine and milling -Plate / Round (Plane washing/ Peeling Machine)

Block Cutting(Customized Size)

Machine Grinding (Grinding Machine/ / Cold Draw Machine)

Side Milling / Round Milling(Plate: 2 / 4 / 6 side milling) / (Round:Cold draw/ Grinding/ Turned, Etc.)

A. Steel plates: Cutting by bandsaw machine, milling, heat treatment, etc

B. Round bars: Cutting by bandsaw machine, peeling, grinding and turned, heat treatment, etc

Company Profile

From 1989 to now, Kingmetal Steel focus on manufacturing and distributing pipeline products including piping, fitting, flange, valve and fastener in stainless, carbon, alloy and duplex steel.

Kingmetal has a factory to manufacture seamless stainless steel pipe from DN6 to DN600 and distribute seamless steel pipe and fitting from top brand manufacturers such as Baosteel, Hengsteel, Tiansteel and Pansteel etc.

All of products are strictly compliance with standard, 100% inspection passed including visual, dimension and PMI test before shipment.

Both our sales and logistic teams are over 10 years of experiences and training frequently.

After- sales service with high efficiency, if any products are short quantity/weight or damaged caused by manufacturing, design or transportation can be compensated.

Why choose us?

One-Stop Solution

We have thousands of total production experience, from raw materials to finished products.

Competitive Price

Large scale purchase, standardized production process and efficient management make our price competitive.

Quick Shipping

Years of export experience enable us to control the transportation time more accurately.

Quality Control

The standardized production process, comprehensive management system, professional testing equipment

Special material customization

We support the customization of various complex materials

OEM/ODM

We support any form of OEM/ODM customization requirements.

D2 steel is a high wear resistant micro deformation cold working die steel, belonging to air hardening tool steel. With high quality fraction of carbon and high chronic, the hardness can up to 60HRC after heat treatment, but malleability,toughness,rust resistance is not good and the surface of the steel is also difficult to be polished.

With the development of cold stamping products moving towards high accuracy,high efficiency, varieties, we require the mould steel should has good wear resistance and high toughness.

Compared with Cr12MoV steel, this D2 die steel adds Mo,V compositions,changed the steel cast structure, improved the morphology of ledeburite , toughness and wear resistance are better than Cr12MoV steel, improved the service life as well.Because of the yield point and plastic deformation resistance is higher than Cr12MoV steel, so that forging performance and hot molding properties are a little weak than Cr12MoV steel.

Features

- High wear resistance

- High compressive strength

- Good dimensional stability

- Good processability

- Excellent resistance to temper softening

- Good toughness

| Chinese | American | German | Japanese |

| GB | AISI | DIN | JIS |

| Cr12Mo1V1 | D2 | 1.2379 | SKD11 |

| Grades | C | Si | Mn | P | S | Cr | Mo | V |

| 1.2379 | 1.5-1.6 | 0.1-0.4 | 0.15-0.45 | ≤0.003 | ≤0.03 | 11-12 | 0.6-0.8 | 0.9-1.1 |

| D2 | 1.4-1.6 | 0.3-0.5 | 0.3-0.5 | ≤0.03 | ≤0.03 | 11-13 | 0.7-1.2 | 0.8 |

| Cr12Mo1V1 | 1.4-1.6 | ≤0.6 | ≤0.6 | ≤0.03 | ≤0.03 | 11-13 | 0.7-1.2 | 0.5-1.1 |

| SKD11 | 1.4-1.6 | ≤0.4 | ≤0.6 | ≤0.03 | ≤0.03 | 11-13 | 0.8-1.2 | 0.2-0.5 |

Heat Treatment

| Quenching | Tempering | ||||

| Heating Temperature/ºC | Cooling | Hardness/HRC | Heating Temperature/ºC | Cooling | Hardness/HRC |

| 980-1040 | Oil or air | 60-65 | 180-220 | Air | 60-64 |

| 1060-1100 | 60-65 | 510-540 | 60-64 | ||

Blanking Mold

Roller

bending mold

Cutting tool&knife

Stock Size

| Flat Bar | Thickness | 6-200mm |

| Width | 155-810mm | |

| Length | 3000-5000mm | |

| Round Bar | Diameter | 6-220mm |

| Length | 3000-5000mm |

Antirust oil, Pearl Film, Spacer, Kraft Paper, Wooden Case, Wooden Frame, Ect.

Accept Customized Packing.

Services

Sawing-to-size- Flate/ Round (Vertical Cutting/ Horizontal Cutting machine)

Machine and milling -Plate / Round (Plane washing/ Peeling Machine)

Block Cutting(Customized Size)

Machine Grinding (Grinding Machine/ / Cold Draw Machine)

Side Milling / Round Milling(Plate: 2 / 4 / 6 side milling) / (Round:Cold draw/ Grinding/ Turned, Etc.)

A. Steel plates: Cutting by bandsaw machine, milling, heat treatment, etc

B. Round bars: Cutting by bandsaw machine, peeling, grinding and turned, heat treatment, etc

Company Profile

From 1989 to now, Kingmetal Steel focus on manufacturing and distributing pipeline products including piping, fitting, flange, valve and fastener in stainless, carbon, alloy and duplex steel.

Kingmetal has a factory to manufacture seamless stainless steel pipe from DN6 to DN600 and distribute seamless steel pipe and fitting from top brand manufacturers such as Baosteel, Hengsteel, Tiansteel and Pansteel etc.

All of products are strictly compliance with standard, 100% inspection passed including visual, dimension and PMI test before shipment.

Both our sales and logistic teams are over 10 years of experiences and training frequently.

After- sales service with high efficiency, if any products are short quantity/weight or damaged caused by manufacturing, design or transportation can be compensated.

Why choose us?

One-Stop Solution

We have thousands of total production experience, from raw materials to finished products.

Competitive Price

Large scale purchase, standardized production process and efficient management make our price competitive.

Quick Shipping

Years of export experience enable us to control the transportation time more accurately.

Quality Control

The standardized production process, comprehensive management system, professional testing equipment

Special material customization

We support the customization of various complex materials

OEM/ODM

We support any form of OEM/ODM customization requirements.