Basic Info.

Model NO.

steel bar

Special Use

Cold Heading Steel, Mold Steel

Application

Machine Parts

Supply Condition

Qt/Normalized/Only Forged

Ultrasonic Test

Sep1921-84 Calss C/C D/D

Tolerance

-0/+5mm for Diameter

Forged Parts

Forging Rings

Transport Package

Seaworth Packaging

Specification

Diameter: 200mm-1000mm

Trademark

Shandong

Origin

China

Production Capacity

2000tons

Product Description

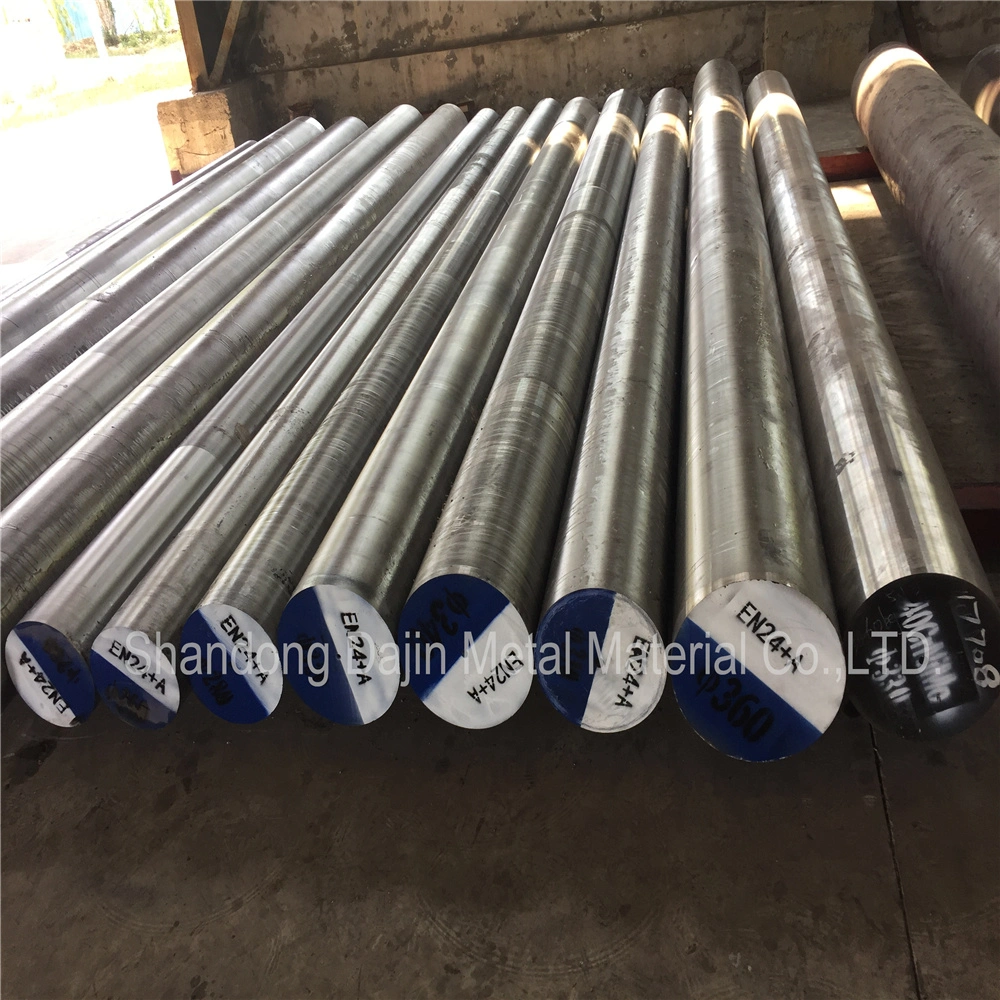

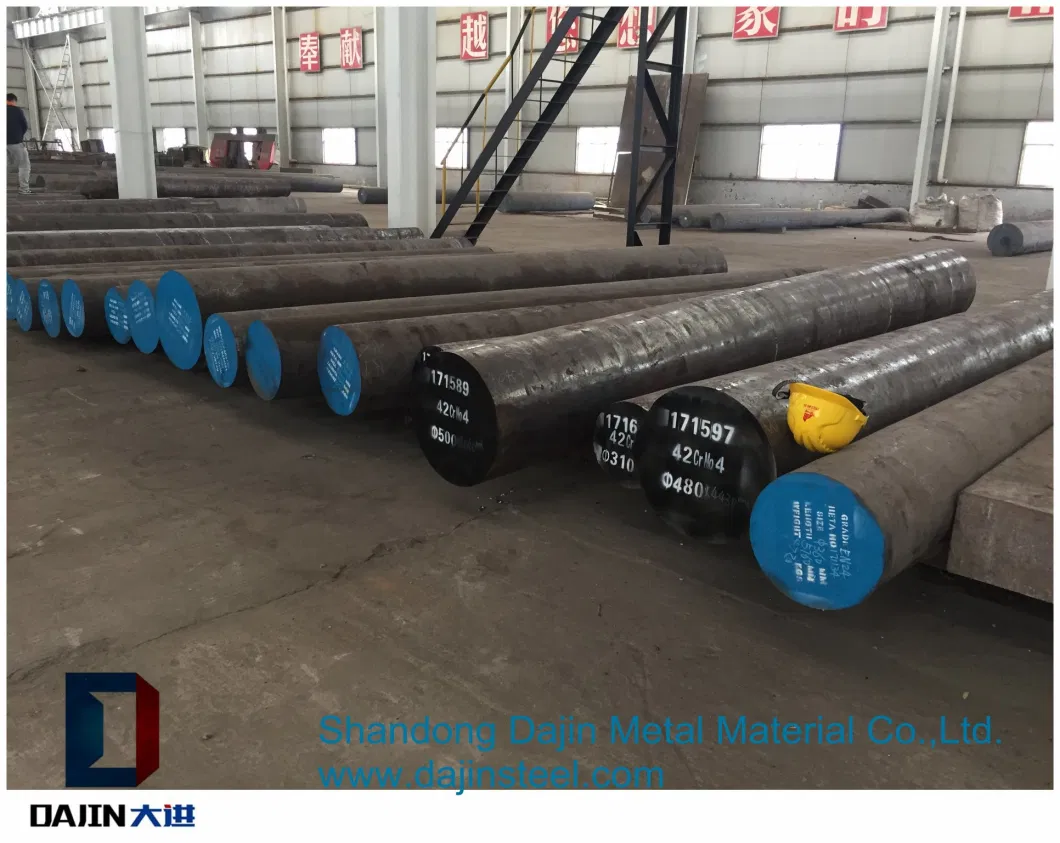

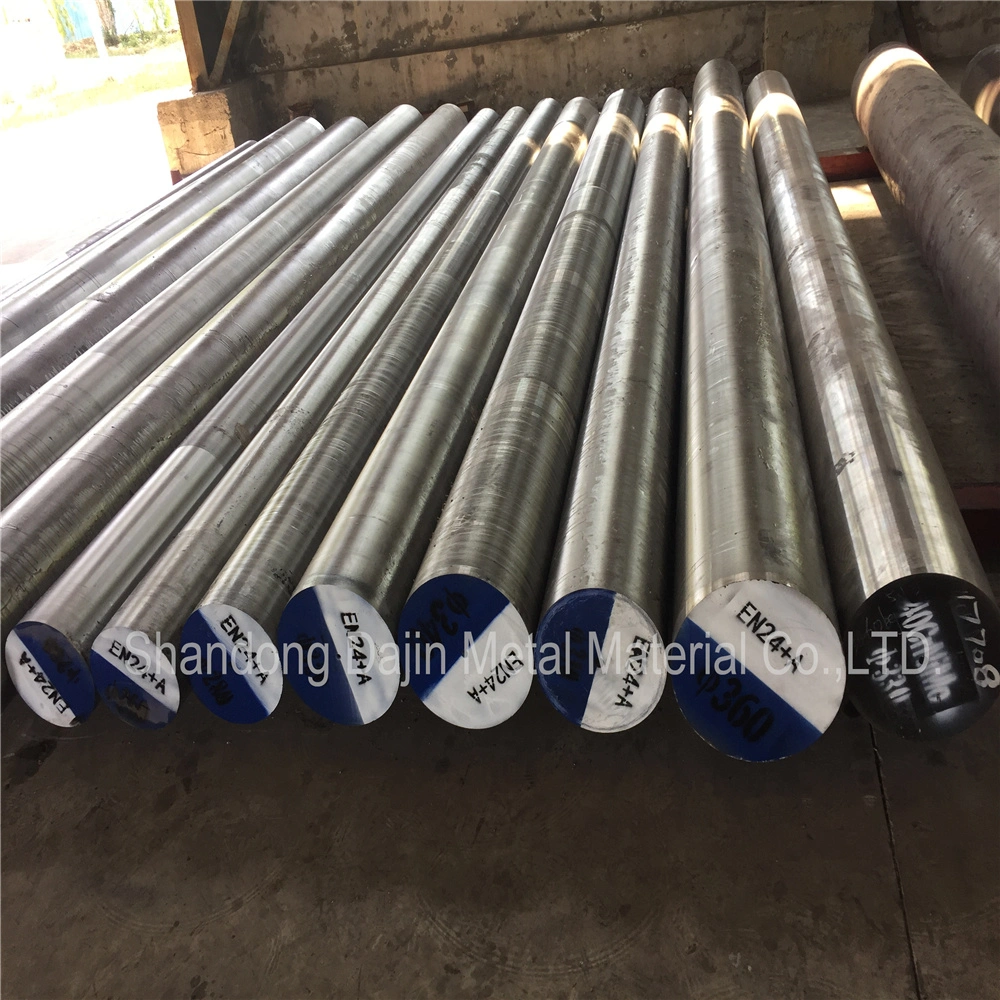

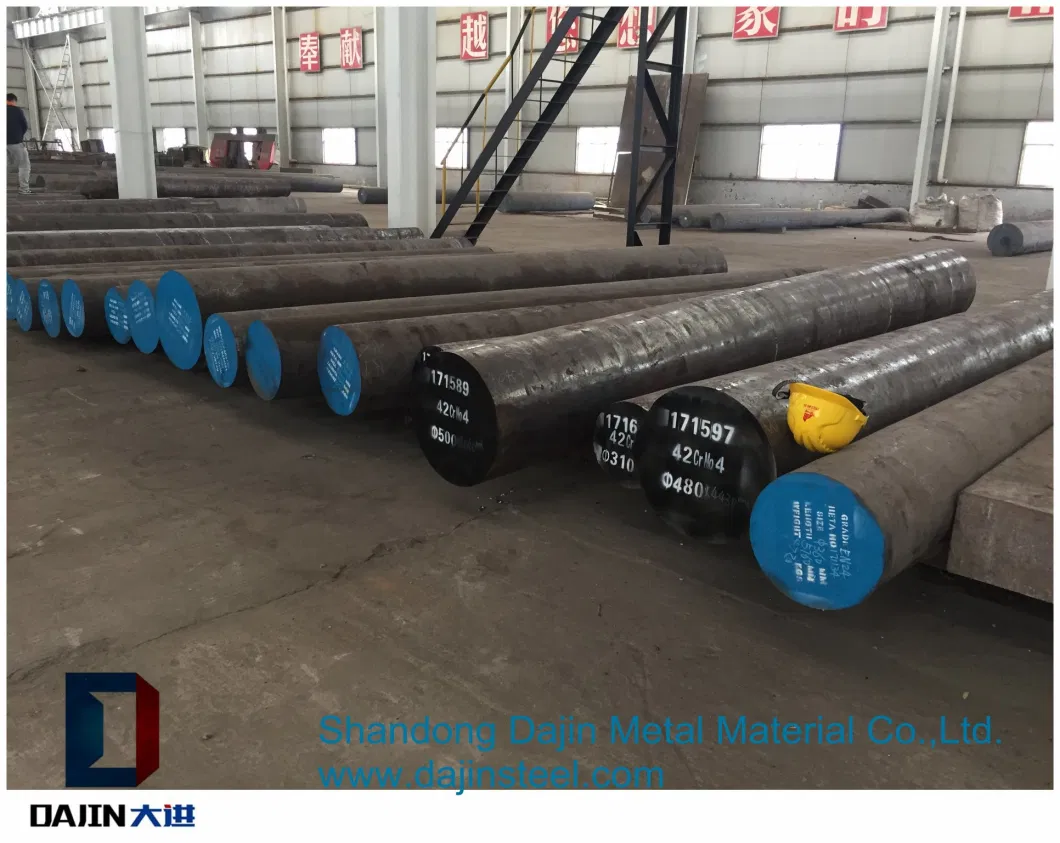

4140 SCM440 42CrMo4 1.7225 Hot Forged Alloy Steel Bar

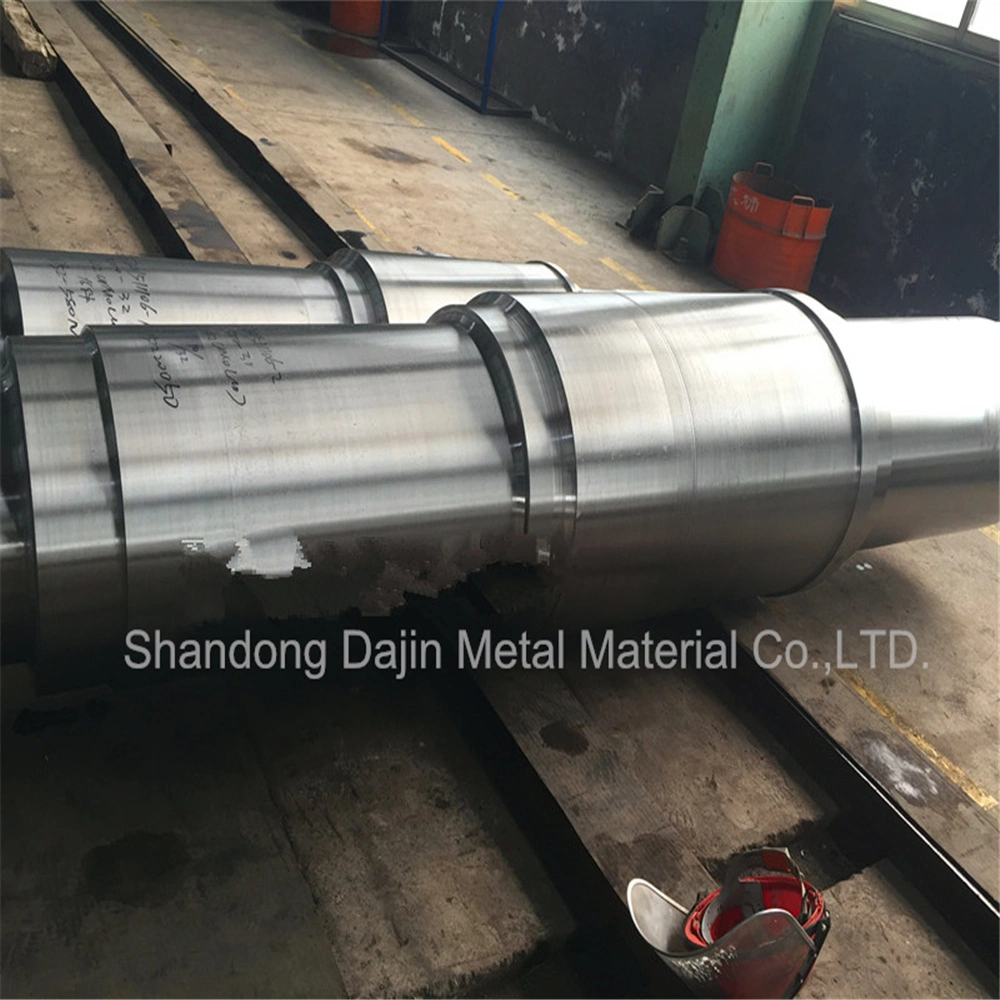

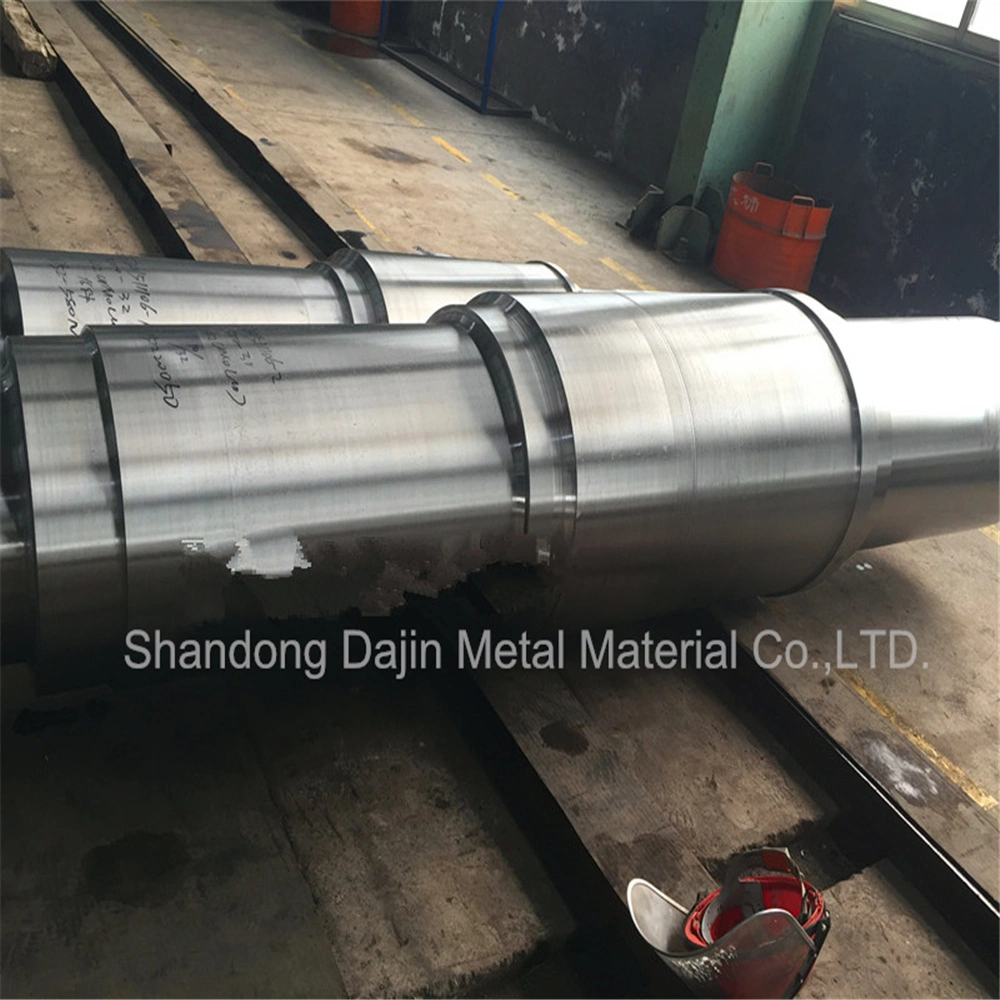

Forging partsForging rings

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | V | Al |

| 0.38/0.43 | 0.15/0.35 | 0.65/0.85 | <=0.025 | <=0.025 | 0.7/0.9 | 1.65/2.0 | 0.2/0.3 | <=0.2 | <=0.05 | 0.02/0.05 |

Process: Forged from vacuum degassed ingots.

Shape: Round /Square/Plat/shaft/block

| Similar grade in different standard | SAE4140/1.7225/SCM440/42CrMo4/42CrMo |

| Available sizes | Forged steel round bar:200mm-800mm Forged steel square:block200mm*200mm-500mm*500mm Forged steel flat block (150mm-500mm)*(200mm-500mm) Forged Shaft:according to client's drawing,we also can supply drawing according to client's requirement |

| Production Process | EAF+LF+VD ( necessary) +forged+UT+ rough machined(optional) +UT+ Heat Treatment (optional)+UT+Precision machining |

| Delivery condition | Forged+black surface Forged+rough machined Forged+rough turned+QT/annealed/normalized |

| Heat treatment: | Normalized / Annealed / Quenched / tempered (optional) |

| Applications | Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears. |

| Inspection | Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,100% UT test according to :SEP1921-84,GR.3 CLASS C/c or D/d |

| Packing situation | standard seaworthy packing or as customer required |

| Delivery time | 7days for stock,30days for new material |

| Payment term | T/T or L/C |

| Our mill's certificates | ISO901&ISO.TS16949,ISO4001,OHSAS18001 Special Equipment Manufacturing License of P.R.C for pipeline plate,steel plate for boiler&Vessel; ISO/TS16949 2009;Europe CE Mark Certificate;JIS MARK,KS MARK. |

Factory Quality Control

PO=>Make production plan(By professional QA team)=>Select perfect raw material(100% checked by Metal Analyzer)=>Cut raw material(marking transfer)=>Heating&forged(production record to control the forge ratio=>HT after forged(Time&TEMP record)=>check black forged(grain size,UT&Sizes)=>rough machining(UT&Sizes)=>Heat treatment(controlled by computers)=>check mechanical property&hardness(universal testing machine&KING hardness tester)=>Semi finish machining(UT,MT&sizes)=>final check(all QC records)=>Packing&warehousing(all docs)=>delivery on time

Our advantage

- Computer-Aided Design (CAD) System

- Multiple Wire EDM (Electric Discharge Machining) Machines

- Plunge EDM (Solid Electrode Electric Discharge Machining)

- Complete Manufacturing of Carbide Dies

- Contoured Straightener Rolls

- Profile Shape Shear Knives

- Fast Tooling Changes and Modifications

- An Advanced Quality Planning System Used for Prototyping

Keywords:forged steel bar/alloy steel bar/carbon steel round bar/hot forging steel bar/4140 steel bar/CK45 steel round bar/forging parts/forged rings/forged steel bar/alloy steel bar/carbon steel round bar/hot forging steel bar/4140 steel bar/CK45 steel round bar/forging parts/forged rings/forged steel bar/alloy steel bar/carbon steel round bar/hot forging steel bar/4140 steel bar/CK45 steel round bar/forging parts/forged rings