Basic Info.

Technique

Punching, Cutting, Bending, Welding,etc.

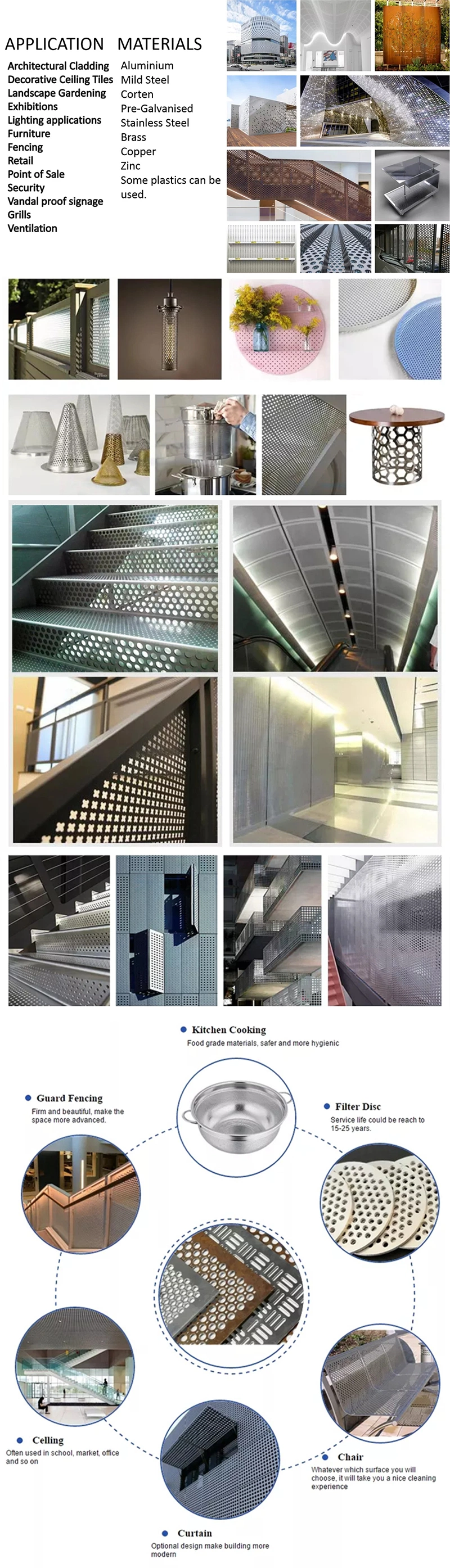

Application

Aerospace,Appliances,Audio Equipment,Automotive...

Special Use

Protective ,Occlude

Stock

Stock

Thickness

0.3-12.0mm or as Request.

Width

1200mm, 1220mm or as Request.

Tolerance

±1%

Steel Grade

201, 202,SGCC, Sgcd, Sgce,1050,1060,Q345,Q345A

Delivery Time

8-14 Days

Length

2000mm,2440mm,2400mm or as Request.

Perforated Area Percent

From 7% to 83%

Transport Package

Standard or Customized

Specification

Standard Or Customized

Trademark

Hanhuang

Origin

Jiangsu

HS Code

7219220000

Production Capacity

5000t/Month

Product Description

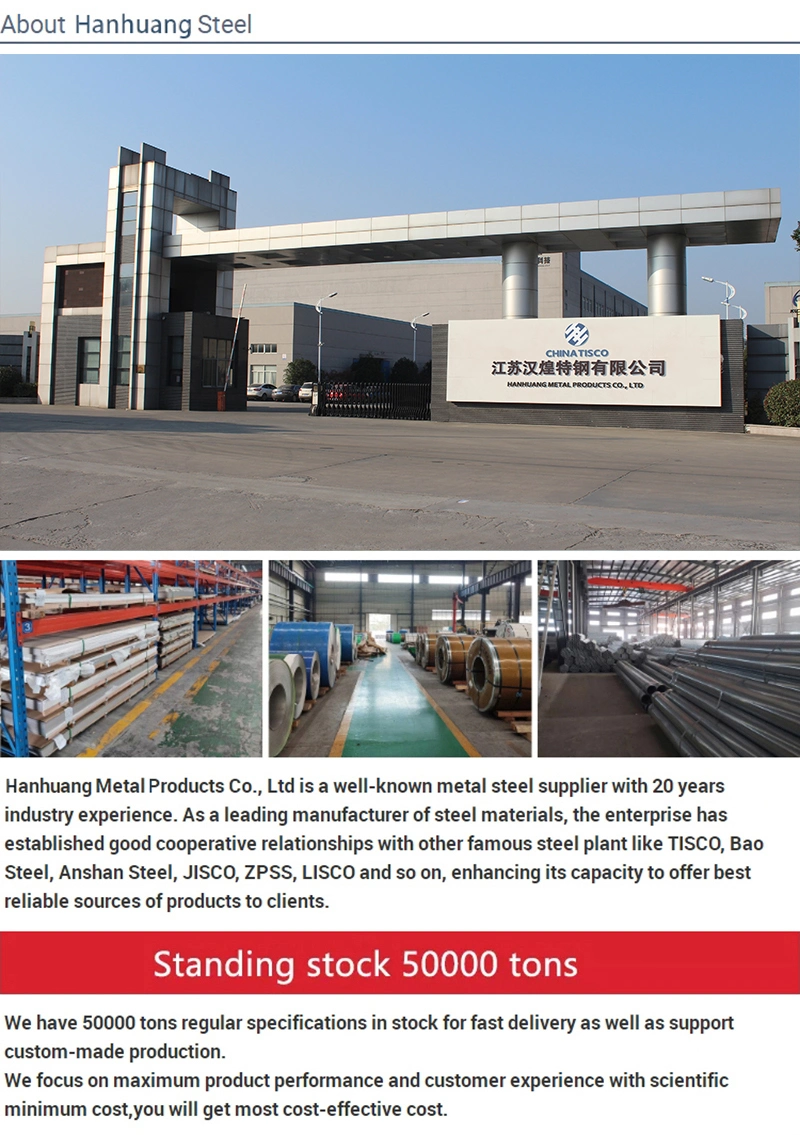

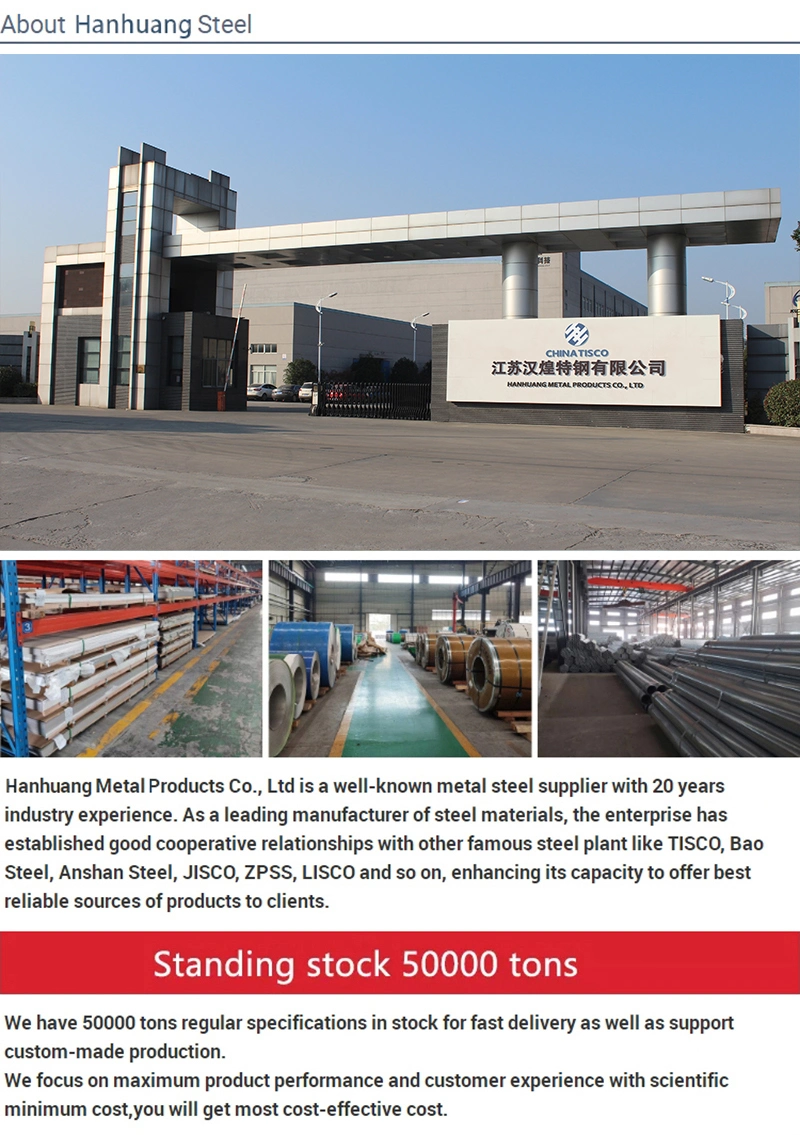

Hanhuang Steel is group company in the steel manufacture & Trading, founded in the 2000s, 800+ staff, 25, 000+ m2 non-dust workshop, 40+ great large mills and cooperation partners in China, 4000, 000+ MT production per year under ISO management, 40, 000+customers in domestic and overseas market, 10 billion USD of annual turnover, 15+ subsidiary companies all over China, ranking the Top 100 private enterprises in China, 1 hour reach Shanghai/Tianjin /Guangzhou Port, we keep high quality, competitive price, thousands tons of stock, most efficient delivery and reliable cooperation for global valued customers. We have been engaging industry steel for over 20 years, best service and the most competitive price is one of our greatest advantages that make us today!

Products Description

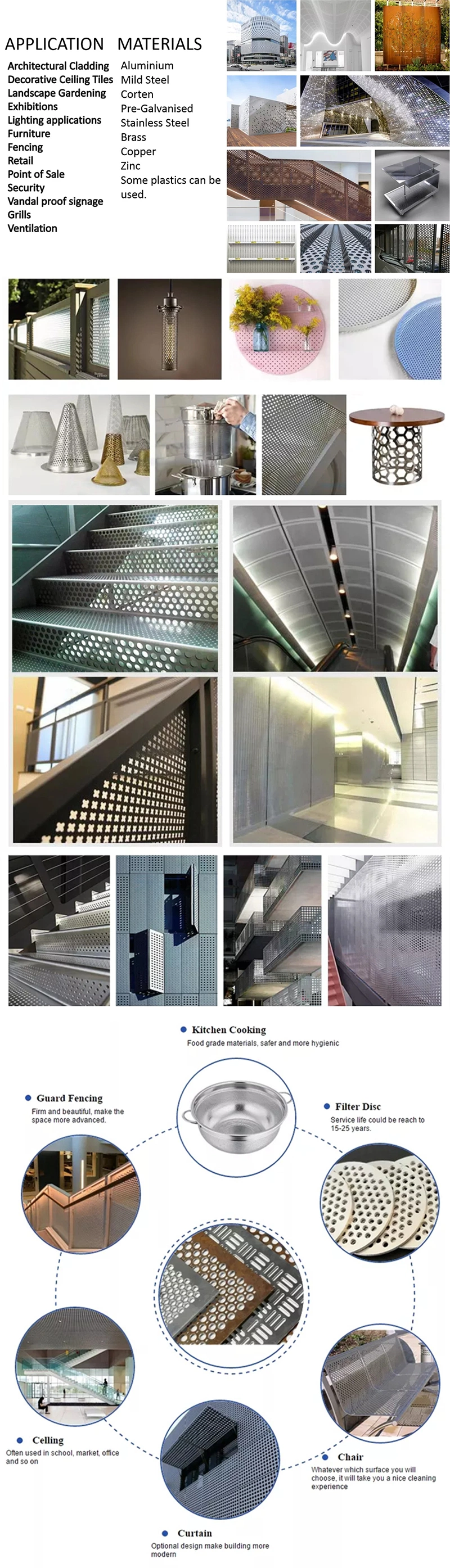

The original name of perforated plate is punched plate, which is the plate obtained by punching on plates of different materials. Material: stainless steel plate, aluminum plate, iron plate, low carbon steel plate, copper plate, etc. Process: different metal plates are cut to the appropriate size and perforated on the NC punch. Hole type: round hole, square hole, prismatic hole, triangular hole, five pointed star hole, oblong hole, etc.

Perforated plate is widely used in real life. It is mainly used to absorb noise and can also be used as decorative plate, which is beautiful and generous. Some can be made into all kinds of utensils, corrosion-resistant, durable, and can be made into kitchen supplies, resistant to high temperature and so on.

The original name of perforated plate is punched plate, which is the plate obtained by punching on plates of different materials. Material: stainless steel plate, aluminum plate, iron plate, low carbon steel plate, copper plate, etc. Process: different metal plates are cut to the appropriate size and perforated on the NC punch. Hole type: round hole, square hole, prismatic hole, triangular hole, five pointed star hole, oblong hole, etc.

Perforated plate is widely used in real life. It is mainly used to absorb noise and can also be used as decorative plate, which is beautiful and generous. Some can be made into all kinds of utensils, corrosion-resistant, durable, and can be made into kitchen supplies, resistant to high temperature and so on.

Specification

| Product name | Perforated metal (also known as perforated sheet, stamping plates, or perforated screen) |

| Material | Carbon Steel, Aluminium,Stainless steel, Bronze, Brass, Titanium, and so on. |

| Thickness | 0.3-12.0mm |

| Hole shape | round, square, diamond, rectangular perforations, octagonal cane, grecian, Diamond, triangle, hexagon etc. |

| plum blossom etc,can be made as your design. | |

| Mesh size | 1220*2440mm,1200*2400mm,1000*2000mm or customized |

| Perforated area percent | from 7% to 83% |

| Production technique | punching, cutting, bending, welding,etc. |

| Role | protective ,occlude |

| Color | as your require |

| Surface treatment | 1.PVC coated |

| 2.Powder coated | |

| 3.Anodized | |

| 4.Paint | |

| 5.Fluorocarbon spraying | |

| 6.Polishing | |

| 7.Electric galvanized, Hot dipped galvanized, PVC coated, oxidation treatment etc | |

| Application | 1.Aerospace: nacelles, fuel filters, air filters |

| 2.Appliances: dish washer strainers, microwave screens, dryer and washer drums, cylinders for gas burners, water heaters and heat pumps, flame arrestors | |

| 3.Architectural: stairs, ceilings, walls, floors, shades, decorative, sound absorption | |

| 4.Audio Equipment: speaker grills | |

| 5.Automotive: fuel filters, speakers, diffusers, muffler guards, protective radiator grills | |

| 6.Food Processing: trays, pans, strainers, extruders | |

| 7.Furniture: benches, chairs, shelves | |

| 8.Filtration: filter screens, filter tubes, strainers for air gas and fluids, dewatering filters | |

| 9.Hammer mill: screens for sizing and separating | |

| 10.HVAC: enclosures, noise reduction, grilles, diffusers, ventilation | |

| 11.Industrial equipment: conveyors, dryers, heat dispersion, guards, diffusers, EMI/RFI protection | |

| 12.Lighting: fixtures | |

| 13.Medical: trays, pans, cabinets, racks | |

| 14.Pollution control: filters, separators | |

| 15.Power generation: intake and exhaust manifold silencers | |

| 16.Mining: screens | |

| 17.Retail: displays, shelving | |

| 18.Security: screens, walls, doors, ceilings, guards | |

| 19.Ships: filters, guards | |

| 20.Sugar processing: centrifuge screens, mud filter screens, backing screens, filter leaves, screens for dewatering and desanding, diffuser drainage plates | |

| 21.Textile: heat setting | |

| Features | 1.can be formed easily |

| 2.can be paint or polished | |

| 3.easy installation | |

| 4.attractive appearance | |

| 5.wide range of thicknesses available | |

| 6.largest selection of hole size patterns and configurations | |

| 7.uniform sound abatement | |

| 8.light weight | |

| 9.durable | |

| 10.superior abrasion resistance | |

| 11.accuracy of size | |

| Package | 1.On pallet with waterproof cloth |

| 2.In wooden case with waterproof paper | |

| 3.In carton box | |

| 4.In roll with woven bag | |

| 5.In bulk or In bundle | |

| Certification | ISO9001,ISO14001,BV,SGS Certificate |

| Materials | Grade | |

| Stainless steel | 200series | 201, 202, 202cu, 204 |

| 300series | 301, 302, 303, 304, 304L, 304H, 309, 309s, 310, 310S, 316, 316L, 316H, 316Ti, 317L, 321, 347 | |

| 400series | 409,409L,410,420,430,431,440 | |

| Duplex/Super Duplex Stainless | Duplex2205/s31803/s32205, Duplex2507, S32750, S32760 | |

| Nickel-base Alloy | S31254, N08367, N08926, N08904, N08020, N06600, N06625, N08825, N08031, N06059, N10276, N06022, N10665, N10665, N10675, | |

| N02200/N02201, N08800, N08810, S30815 | ||

| Others | 330/N08330, 333/N06333, 660, 630, 631, 17-4ph, 17-7 ph, etc. | |

| Galvanized steel | SGCC, SGCD, SGCE | |

| DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z | ||

| S250GD+Z,S280GD+Z, S350GD+Z,S550GD+Z | ||

| Aluminium steel | 1000 Series:1050,1060,1080,1100,1435,etc. | |

| 2000 Series:2011,2014,2017,2024,2A12,2A16,2A06,etc. | ||

| 3000 Series:3002,3003,3004,3104,3204,3030,3A21,etc. | ||

| 5000 Series:5005,5025,5040,5052,5056,5083,5A05,etc. | ||

| 6000 Series:6003,6060,6082,6083,6063,6061,etc. | ||

| 7000 Series:7003,7005,7050,7075,etc. | ||

| carbon steel | Q195, Q215, Q235, Q345, ST37, A36, 45#, 16Mn, SPHC, Q345,Q345A,,Q345B,Q345C,Q345D,Q345E,Q235B scm415 HC340LA,HC380LA,HC420LA B340LA,B410LA 15CRMO,12Cr1MoV,20CR,40CR,65MN 4140 42CrMo 4340 A709GR50 1045 S45C 45# | |

| ...... | ...... | |

| Plate thickness | Hole width | Hole length | Stem | Mesh width | Mesh length | Weigtht |

| (mm) | (mm) | (mm) | (m) | (m) | (kg/m2) | |

| 0.5 | 2.5 | 4.5 | 0.5 | 0.5 | 1 | 1.8 |

| 0.5 | 10 | 25 | 0.5 | 0.6 | 2 | 0.73 |

| 0.6 | 10 | 25 | 1 | 0.6 | 2 | 1 |

| 0.8 | 10 | 25 | 1 | 0.6 | 2 | 1.25 |

| 1 | 10 | 25 | 1.1 | 0.6 | 2 | 1.77 |

| 1 | 15 | 40 | 1.5 | 2 | 4 | 1.85 |

| 1.2 | 10 | 25 | 1.1 | 2 | 4 | 2.21 |

| 1.2 | 15 | 40 | 1.5 | 2 | 4 | 2.3 |

| 1.5 | 15 | 40 | 1.5 | 1.8 | 4 | 2.77 |

| 1.5 | 23 | 60 | 2.6 | 2 | 3.6 | 2.77 |

| 2 | 18 | 50 | 2.1 | 2 | 4 | 3.69 |

| 2 | 22 | 60 | 2.6 | 2 | 4 | 3.69 |

| 3 | 40 | 80 | 3.8 | 2 | 4 | 5 |

| 4 | 50 | 100 | 4 | 2 | 2 | 11.15 |

| 4.5 | 50 | 100 | 5 | 2 | 2.7 | 11.15 |

| 5 | 50 | 100 | 5 | 1.4 | 2.6 | 12.39 |

| Material | Thickness(MM) | Hole (MM) | Pitch(MM) | Dimension(M) | Pack type |

| Stainless Steel 201,202,304, 316,310,2205, etc | 0.2 | 0.5-6.0 | 1.2-6 | 1*20 or 0.5*0.5 | roll or sheet |

| 0.35 | 0.5-6.0 | 1.4 at least | 1*20 or 0.5*0.5 | roll or sheet | |

| 0.45 | 0.5-6.0 | 1.1at least | 1*20 or 0.5*0.5 | roll or sheet | |

| 0.5 | 0.8-6.0 | 1.5 at least | 1*20 or 0.5*0.5 | roll or sheet | |

| 0.8 | 1.0-10 | 2 at least | 1*20 or 0.5*0.5 | roll or sheet | |

| 1 | 1.2-10 | 2.7 at least | 1*2M | Sheet | |

| 1.2 | 1.2-10 | 2.7 at least | 1*2M | Sheet | |

| 1.5 | 1.5 | 3.0 at least | 1*2M | Sheet | |

| 2 | >=2.0 | >=4.0 | 1*2M | Sheet | |

| 3 | >=3.0 | >=6.0 | 1*2M | Sheet | |

| 4 | >=4.0 | >=8.0 | 1*2M | Sheet | |

| 5 | >=5.0 | >=10.0 | 1*2M | Sheet | |

| 6 | >=6.0 | >=12.0 | 1*2M | Sheet |

| Iso approved wholesale corten steel galvanized perforated metal | ||||||

| Opening (mm) | Center type(mm) | The thickness of the sheet (mm)min-max | Size (mm) | Stainless | Iron | Aluminum |

| Steel | ||||||

| 1 | ≥2 | 0.4---1 | 1220×2440 | √ | √ | √ |

| 1.5 | ≥2.5 | 0.4-1 | 1220×2440 | √ | √ | √ |

| 2 | ≥3 | 0.4-2 | 1220×2440 | √ | √ | √ |

| 2.5 | ≥3.5 | 0.4-2.5 | 1220×2440 | √ | √ | √ |

| 3 | ≥4 | 0.4-3 | 1220×2440 | √ | √ | √ |

| 4 | ≥5.5 | 0.44 | 1220×2440 | √ | √ | √ |

| 5 | ≥6.5 | 0.4__5 | 1220×2440 | √ | √ | √ |

| 6 | ≥8 | 0.4-5 | 1220×2440 | √ | √ | √ |

| 7 | ≥9 | 0.4-6 | 1220×2440 | √ | √ | √ |

| 8 | ≥10 | 0.57.5 | 1220×2440 | √ | √ | √ |

| 9 | ≥11 | 0.58 | 1220×2440 | √ | √√ | √ |

| 10 | ≥12 | 0.6---8 | 1220×2440 | √ | √ | √ |

| 12--20 | ≥15-24 | 0.8---6 | 1220×2440 | √ | √ | √ |

| 21-30 | ≥25-36 | 1.0--6 | 1220×2440 | √ | √ | √ |

| Above specifications for reference only, specifications can be customized according to user needs. | ||||||

| Low carbon steel perforated sheet specification | |||

| Standard Size | Hole | Pitch | Opening area % |

| 26 | .020" | .043" | 20% |

| 26 | .027" | .050" STRAIGHT | 23% |

| 22 | 1/32" | 1/16" | 22% |

| 22-18 | 3/64" | 3/32" | 23% |

| 24 | .050" | .066" STRAIGHT | 45% |

| 22-18 | 1/16" | 3/32" | 45% |

| 16 | 1/16" | 7/64" | 30% |

| 20-16 | 1/16" | 1/8" | 23% |

| 20-14 | 5/64" | 1/8" | 36% |

| 20-14 | 3/32" | 5/32" | 33% |

| 24 | 3/32" | 3/16" | 23% |

| 18 | .117" | 5/32" | 51% |

| 22,18-14,11 | 1/8" | 3/16" | 40% |

| 12 | 1/8" | 7/32" | 29% |

| 18 | 9/64" | 3/16" | 51% |

| 20-16 | 5/32" | 3/16" | 63% |

| 20,10 | 5/32" | 1/4" | 36% |

| 22,18,16 | 3/16" | 7/32" | 67% |

| 24-14 | 3/16" | 1/4" | 51% |

| 18-3/16"PL | 3/16" | 5/16" | 33% |

| 22 | 1/4" | HEX | 79% |

| 22-16 | 1/4" | 5/16" | 58% |

| 20-1/4"PL | 1/4" | 3/8" | 40% |

| 16 | 1/4" | 3/8" STRAIGHT | 35% |

| 18 | 1/4" | 1/2"STRAIGHT | 23% |

| 18-14,10,3/16"1/4"PL | 5/16" | 7/16" | 50% |

| 16-1/4"PL | 3/8" | 9/16" | 40% |

| 20-14,10-1/4"PL | 1/2" | 11/16" | 48% |

| 10-1/4"PL | 5/8" | 7/8" | 46% |

| 16,11,3/16",1/4"PL | 3/4" | 1" | 51% |

| 10-1/4"PL | 1" | 1-3/8" | 48% |

| 3/16",1/4"PL | 1-1/4" | 1-5/8" | 54% |

| 10-1/4"PL | 1-1/2" | 2" | 51% |

| 10-1/4"PL | 2" | 2-1/2" | 58% |

| 10,3/16"PL | 2-1/2" | 3" | 63% |

| 10,1/4"PL | 3" | 3-1/2" | 67% |

| 10 | 3-1/2" | 4" | 70% |

| 10 | 4" | 4-1/2" | 72% |

| Special specification could be produced as customized. | |||

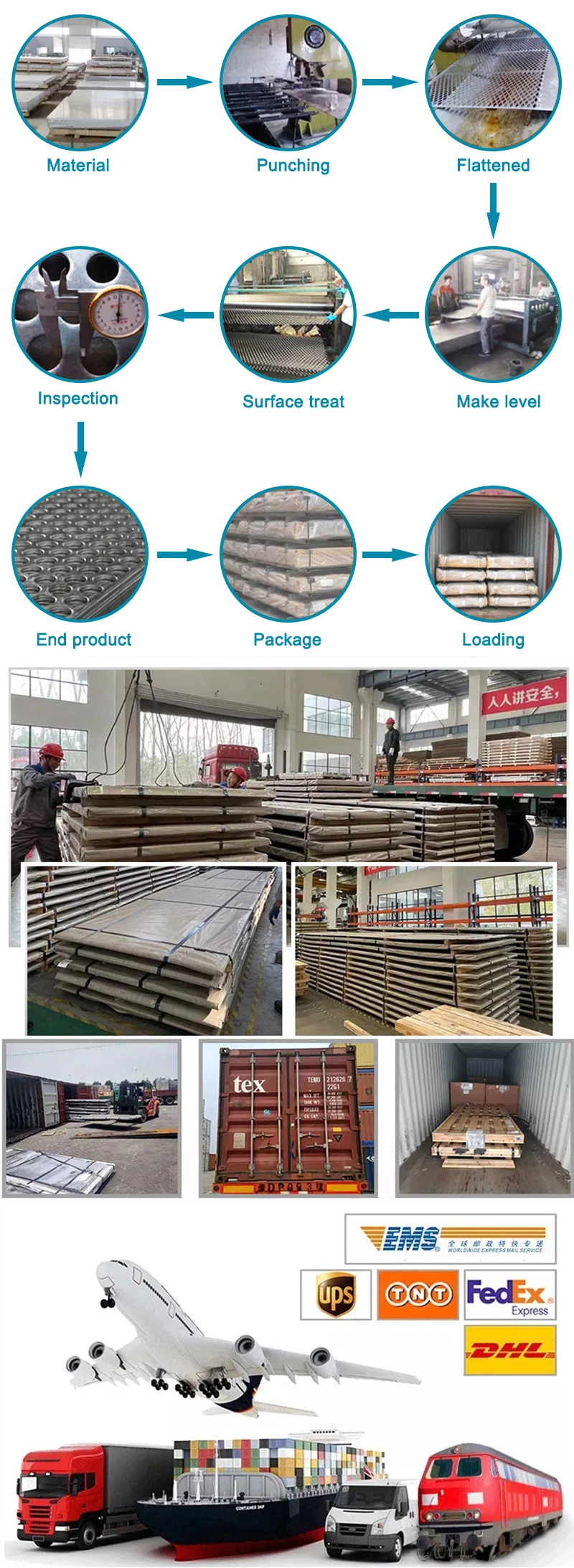

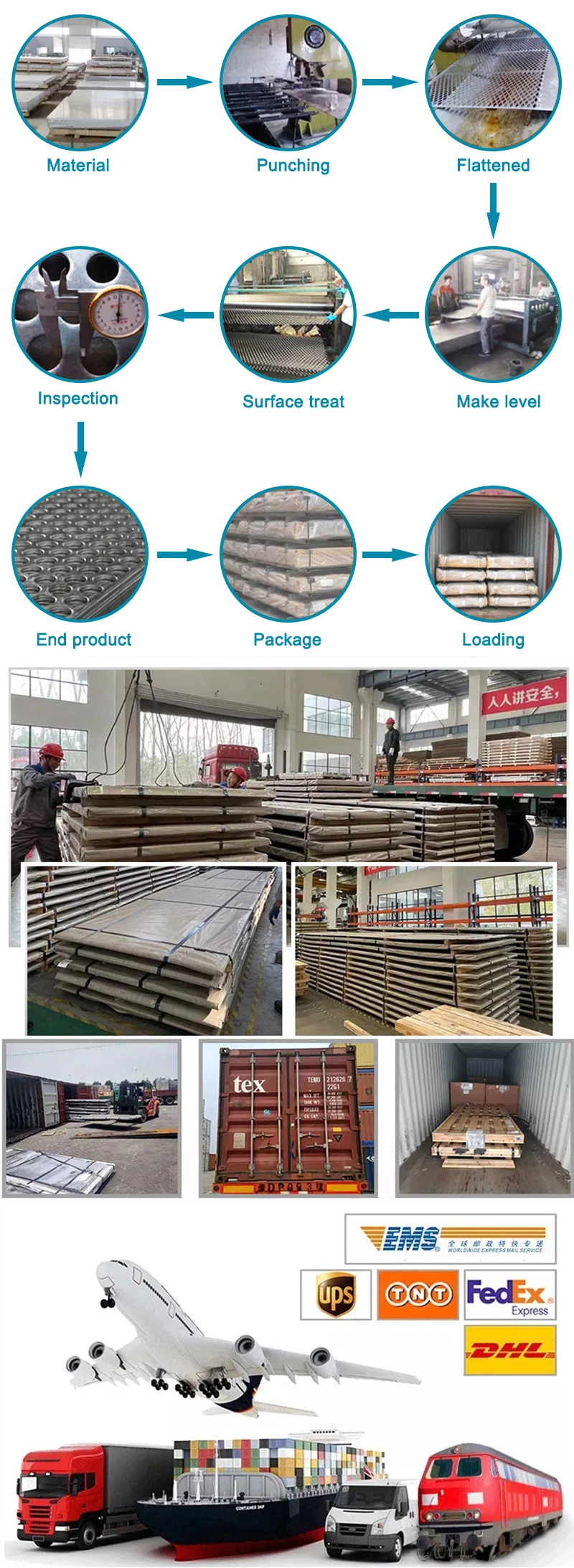

Process

Advantages

Application

Packing & Delivery

Packing & Delivery