Product Description

Details

Brand and material:

Materials: H59, H63, H65, H68, H70, H80, H85, H90, H96, T1, T2, C1100, C5111, C5101, C5191, C5210, TU1, TP1, TP2, TAg0.08, TAg0.1, C1100, C1020, C1201, C1220, C1271, C2100, C2200, C2300, C2400, C2600, C2680, C2700, C2720, C2800, C2801, etc.

Specification: thickness: 1.0-200mm,

Width: 305-600mm.

Hardness: O, 1/2H, 3/4H, H, EH, SH, etc.

H59 ordinary brass; The price is the cheapest, with high strength and hardness and poor plasticity. However, it can still withstand pressure processing well in hot state, and its corrosion resistance is average. Other properties are similar to those of H62. Used for general machine parts, welding parts, hot stamping and hot rolling parts.

H59 ordinary brass; The price is the cheapest, with high strength and hardness and poor plasticity. However, it can still withstand pressure processing well in hot state, and its corrosion resistance is average. Other properties are similar to those of H62. Used for general machine parts, welding parts, hot stamping and hot rolling parts.

H62 ordinary brass; It has good mechanical properties, good plasticity in hot state, good plasticity in cold state, good machinability, easy brazing and welding, corrosion resistance, but easy to produce corrosion cracking. In addition, the price is cheap, and it is a common brass variety used frequently. It is used for the courtesy parts of various deep drawing and bending manufacturing, such as pins, rivets, washers, nuts, conduits, barometer springs, screens, radiator parts, etc.

H63 ordinary brass; It is suitable for cold pressure processing, welding and brazing. Easy to polish, it is the main alloy for wire drawing, rolling, bending, etc. Round roller for screw and pickling, etc.

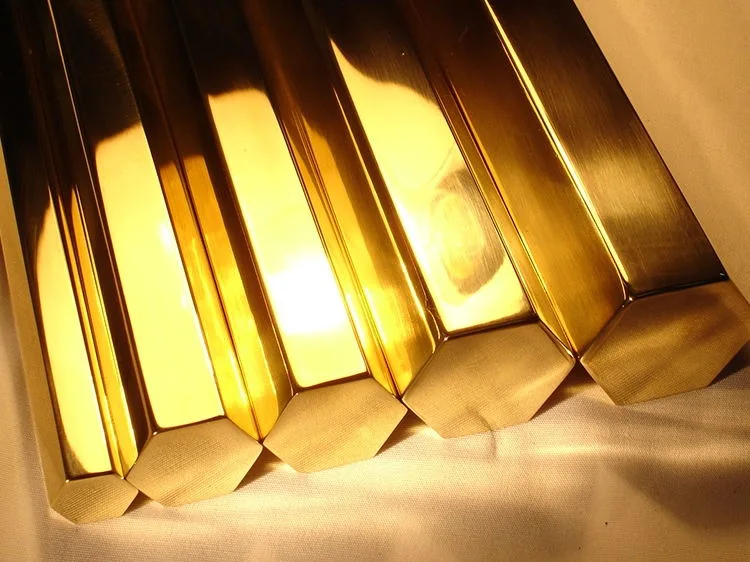

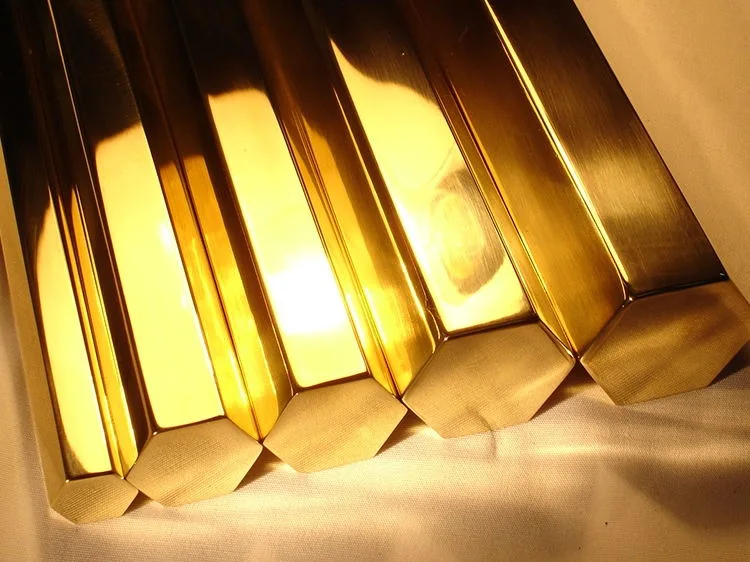

Pictures

H70 is used for complex cold drawing parts and deep drawing parts, such as radiator shell, conduit, bellows, cartridge case and gasket.

H70 is used for complex cold drawing parts and deep drawing parts, such as radiator shell, conduit, bellows, cartridge case and gasket.

H75 ordinary brass; It has fairly good mechanical properties, processing properties and corrosion resistance. It can be well pressed in hot and cold states. It is between H80 and H70 in performance and economy. For low load corrosion resistant springs.

H80 ordinary brass; The performance is similar to H85, but the strength is high, the plasticity is also good, and the corrosion resistance is high in the atmosphere, fresh water and sea water. Used for paper mesh, thin wall pipe, corrugated pipe and building supplies.

H85 ordinary brass; It has high strength, good plasticity, can well withstand cold and hot pressure processing, welding and corrosion resistance. Used for condensation and heat dissipation pipes, siphons, serpentines, cooling equipment parts.

C3601 environment-friendly copper, excellent cutting performance, excellent hot punching, cold heading and ductility, good knurling, riveting and corrosion resistance. High strength, good toughness, widely used in electronic hardware processing industry, cutting riveting processing of various standard parts. It is a widely used lead brass with good machinability, good mechanical properties, ability to withstand cold and hot pressure processing, easy fiber welding and welding, good stability to general corrosion, but with corrosion cracking tendency. It has excellent cutting and drilling performance, high strength and strong corrosion resistance.

C3601 environment-friendly copper, excellent cutting performance, excellent hot punching, cold heading and ductility, good knurling, riveting and corrosion resistance. High strength, good toughness, widely used in electronic hardware processing industry, cutting riveting processing of various standard parts. It is a widely used lead brass with good machinability, good mechanical properties, ability to withstand cold and hot pressure processing, easy fiber welding and welding, good stability to general corrosion, but with corrosion cracking tendency. It has excellent cutting and drilling performance, high strength and strong corrosion resistance.

Packaging & Shipping

About Us

About Us

FAQ

Q: How do I get pricing?

All of our prices are available online on the individual item pages. If you need longer lengths, larger quantities, or material you don't see, we can offer custom quotes.

Q: How do I get a custom quote?

Please sign in to your account and to send a inquiry . One of our sales representatives will respond as quickly as possible. If you don't have an account yet, creating one is simple and offers a wide array of benefits.

Q: How long will this take to be ready?

It depends on the material, but typically the turnaround is 4 business hours. Certain materials, such as thick steel plate or larger quantities, may take longer.

Q: Can I place the order at the warehouse?

No, you still need to place the order online.

How will I know when my order is ready?

We send you an email when it's ready to go. If you have further questions, please contact us.

Q: My order is a small piece, can I come to get it now?

No, you'll still need to wait until the order is ready for pickup.

Frequently Asked Questions

We help thousands of fabricators, designers, engineers, and makers with their material needs each month. After more than 20 years, we've seen that many of our customers have very similar questions about our services and products. Here are some of the most commonly asked questions. If you can't find the answer to your question here, try contact us for more resources.

Products Name | Copper/ Brass / Bronze Sheet | |||

Materials | T1,T2,C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,TP1,TP2, C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,TU1,TU2,C12500, C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000, C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800,C63020, C65500,C68700,C70400,C70600,C70620,C71000,C71500,C71520,C71640,C72200,C83600/ C93200,C62900/C95400/C95500/CuAl10Fe5Ni5,H59,H62,H65,H70 | |||

Standard | GB/T17791-2007,GB/T1527-2006, GB/T18033-2007, YS/T450-2002ASTM B280,ASTM B68,ASTM B75,ASTM B88 EN12735,AS1571,JIS H3300 | |||

Shape | Square,Rectangular | |||

Temper | Soft (M), half soft (M2) and half hard (Y2) | |||

Packing | Individually Sealed Bylastic Bags or Heat Shrinkable Packaging,Wooden Pallet or Carton Box of 3-20 Coils | |||

Materials: H59, H63, H65, H68, H70, H80, H85, H90, H96, T1, T2, C1100, C5111, C5101, C5191, C5210, TU1, TP1, TP2, TAg0.08, TAg0.1, C1100, C1020, C1201, C1220, C1271, C2100, C2200, C2300, C2400, C2600, C2680, C2700, C2720, C2800, C2801, etc.

Specification: thickness: 1.0-200mm,

Width: 305-600mm.

Hardness: O, 1/2H, 3/4H, H, EH, SH, etc.

H59 ordinary brass; The price is the cheapest, with high strength and hardness and poor plasticity. However, it can still withstand pressure processing well in hot state, and its corrosion resistance is average. Other properties are similar to those of H62. Used for general machine parts, welding parts, hot stamping and hot rolling parts.

H59 ordinary brass; The price is the cheapest, with high strength and hardness and poor plasticity. However, it can still withstand pressure processing well in hot state, and its corrosion resistance is average. Other properties are similar to those of H62. Used for general machine parts, welding parts, hot stamping and hot rolling parts.H62 ordinary brass; It has good mechanical properties, good plasticity in hot state, good plasticity in cold state, good machinability, easy brazing and welding, corrosion resistance, but easy to produce corrosion cracking. In addition, the price is cheap, and it is a common brass variety used frequently. It is used for the courtesy parts of various deep drawing and bending manufacturing, such as pins, rivets, washers, nuts, conduits, barometer springs, screens, radiator parts, etc.

H63 ordinary brass; It is suitable for cold pressure processing, welding and brazing. Easy to polish, it is the main alloy for wire drawing, rolling, bending, etc. Round roller for screw and pickling, etc.

Pictures

H70 is used for complex cold drawing parts and deep drawing parts, such as radiator shell, conduit, bellows, cartridge case and gasket.

H70 is used for complex cold drawing parts and deep drawing parts, such as radiator shell, conduit, bellows, cartridge case and gasket.H75 ordinary brass; It has fairly good mechanical properties, processing properties and corrosion resistance. It can be well pressed in hot and cold states. It is between H80 and H70 in performance and economy. For low load corrosion resistant springs.

H80 ordinary brass; The performance is similar to H85, but the strength is high, the plasticity is also good, and the corrosion resistance is high in the atmosphere, fresh water and sea water. Used for paper mesh, thin wall pipe, corrugated pipe and building supplies.

H85 ordinary brass; It has high strength, good plasticity, can well withstand cold and hot pressure processing, welding and corrosion resistance. Used for condensation and heat dissipation pipes, siphons, serpentines, cooling equipment parts.

C3601 environment-friendly copper, excellent cutting performance, excellent hot punching, cold heading and ductility, good knurling, riveting and corrosion resistance. High strength, good toughness, widely used in electronic hardware processing industry, cutting riveting processing of various standard parts. It is a widely used lead brass with good machinability, good mechanical properties, ability to withstand cold and hot pressure processing, easy fiber welding and welding, good stability to general corrosion, but with corrosion cracking tendency. It has excellent cutting and drilling performance, high strength and strong corrosion resistance.

C3601 environment-friendly copper, excellent cutting performance, excellent hot punching, cold heading and ductility, good knurling, riveting and corrosion resistance. High strength, good toughness, widely used in electronic hardware processing industry, cutting riveting processing of various standard parts. It is a widely used lead brass with good machinability, good mechanical properties, ability to withstand cold and hot pressure processing, easy fiber welding and welding, good stability to general corrosion, but with corrosion cracking tendency. It has excellent cutting and drilling performance, high strength and strong corrosion resistance.

Packaging & Shipping

About Us

About UsYegang Iron and Steel (Shandong) Group Co., Ltd., is a professional steel production and sales enterprise, located in Jinan Pilot Free Trade Zone, Shandong Province, close to China's famous ports, Tianjin Port, Qingdao Port, convenient logistics and export, superior production and operation environment, mature industrial facilities, complete related supporting industries.

The company is equipped with a perfect product production line, the main equipment includes cutting machine, bending machine, punch machine, water jet cutting machine, polishing machine, plate shear machine, wire drawing machine, etc.

Quality-oriented, constantly achieve product optimization, to create high-quality steel, is our constant pursuit. The products have passed the national security 3C certification, EU CE certification and ISO9001 international quality system certification.

Quality-oriented, constantly achieve product optimization, to create high-quality steel, is our constant pursuit.

The company is equipped with a perfect product production line, the main equipment includes cutting machine, bending machine, punch machine, water jet cutting machine, polishing machine, plate shear machine, wire drawing machine, etc.

Quality-oriented, constantly achieve product optimization, to create high-quality steel, is our constant pursuit. The products have passed the national security 3C certification, EU CE certification and ISO9001 international quality system certification.

Quality-oriented, constantly achieve product optimization, to create high-quality steel, is our constant pursuit.

FAQ

Q: How do I get pricing?

All of our prices are available online on the individual item pages. If you need longer lengths, larger quantities, or material you don't see, we can offer custom quotes.

Q: How do I get a custom quote?

Please sign in to your account and to send a inquiry . One of our sales representatives will respond as quickly as possible. If you don't have an account yet, creating one is simple and offers a wide array of benefits.

Q: How long will this take to be ready?

It depends on the material, but typically the turnaround is 4 business hours. Certain materials, such as thick steel plate or larger quantities, may take longer.

Q: Can I place the order at the warehouse?

No, you still need to place the order online.

How will I know when my order is ready?

We send you an email when it's ready to go. If you have further questions, please contact us.

Q: My order is a small piece, can I come to get it now?

No, you'll still need to wait until the order is ready for pickup.

Frequently Asked Questions

We help thousands of fabricators, designers, engineers, and makers with their material needs each month. After more than 20 years, we've seen that many of our customers have very similar questions about our services and products. Here are some of the most commonly asked questions. If you can't find the answer to your question here, try contact us for more resources.