Product Description

Product Description

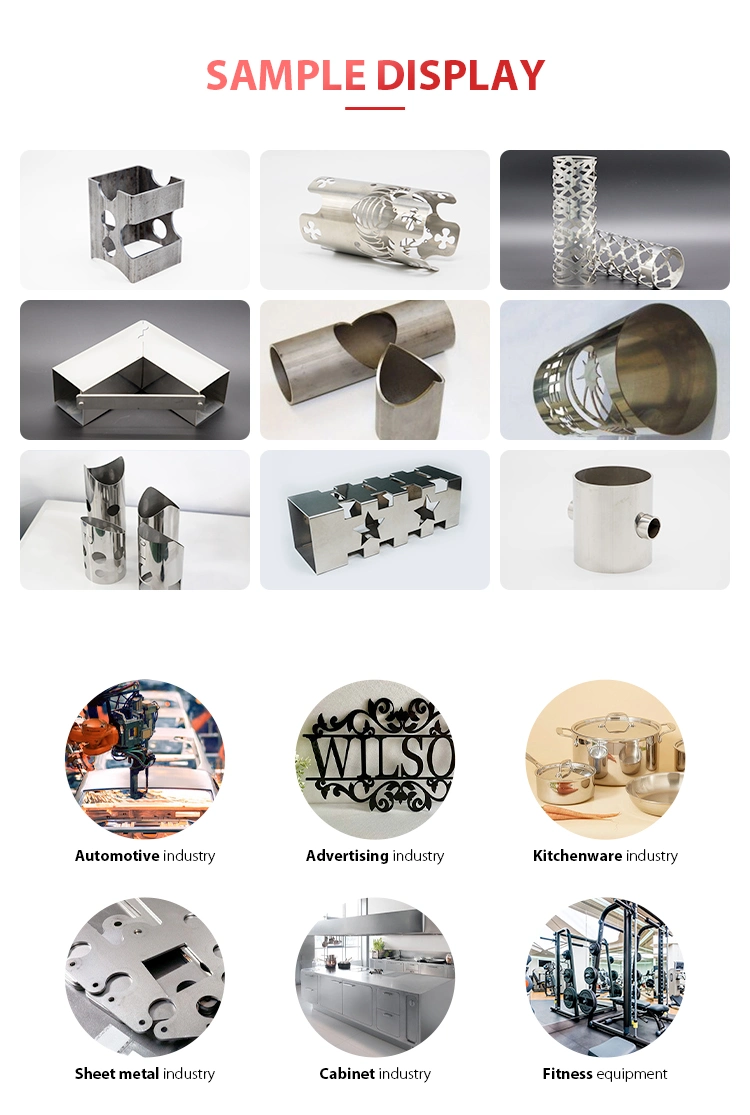

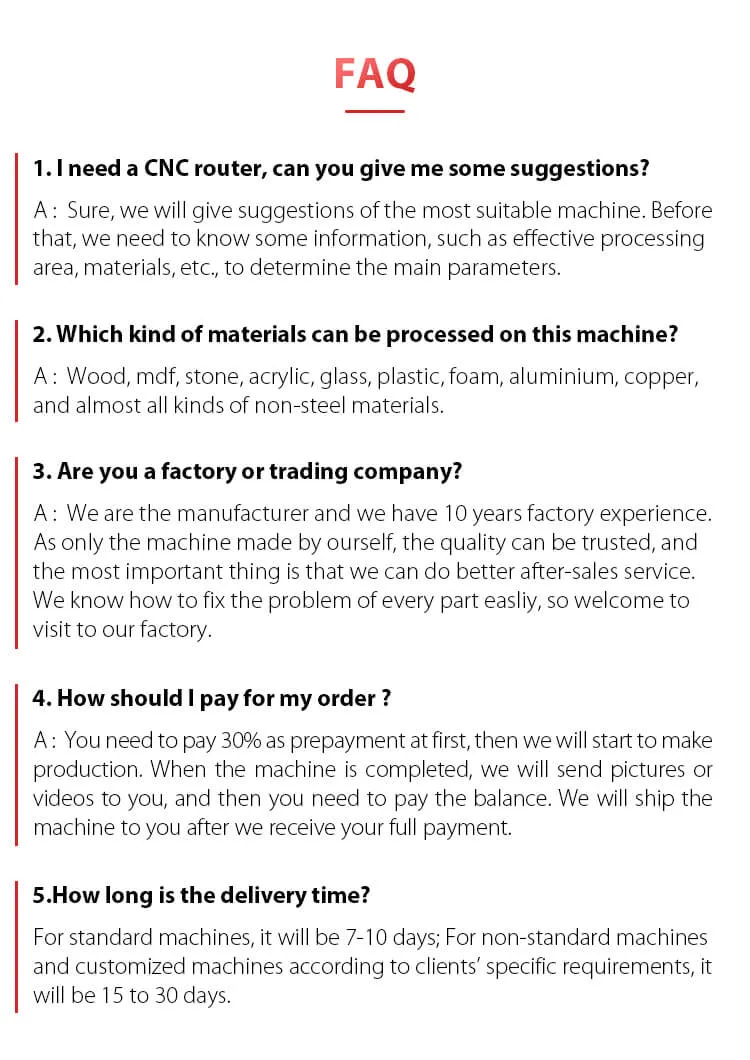

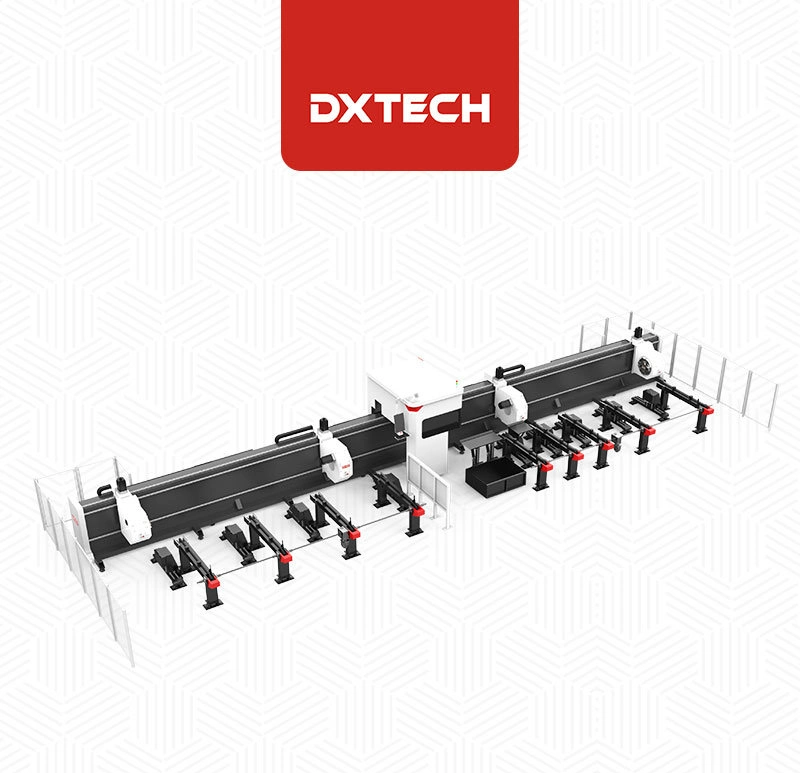

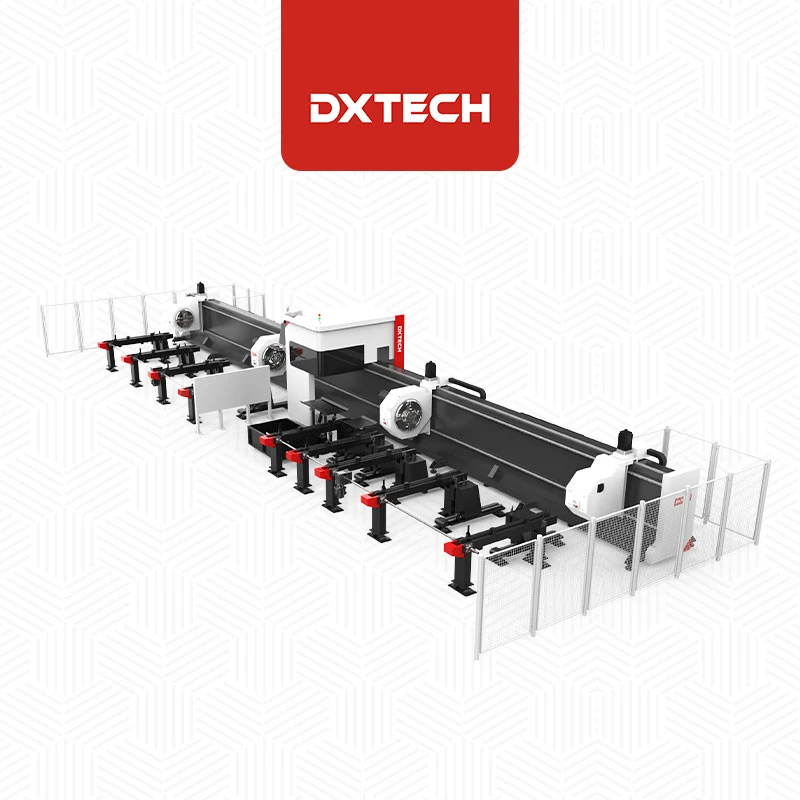

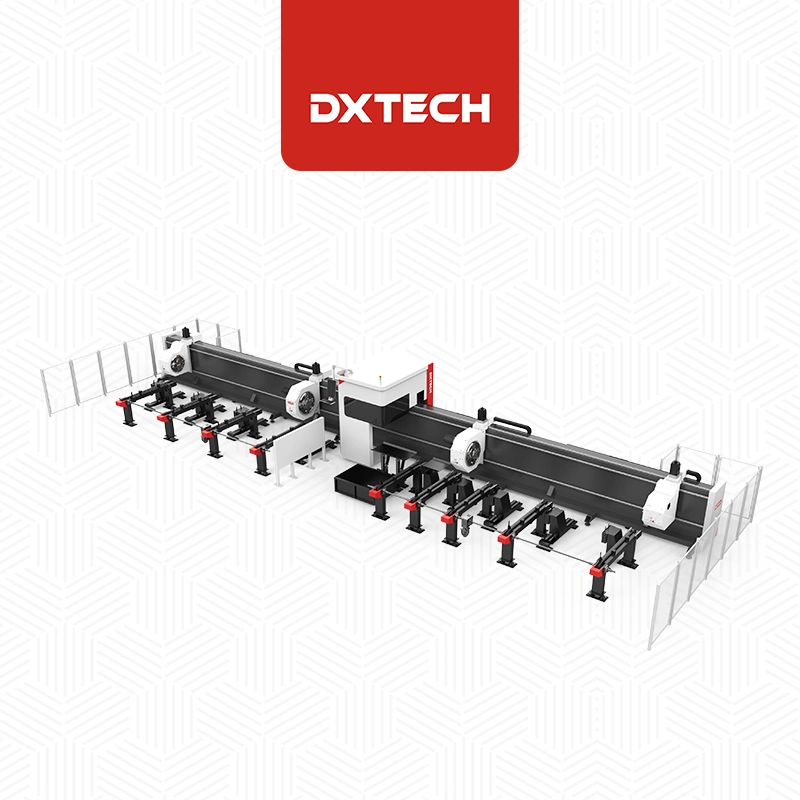

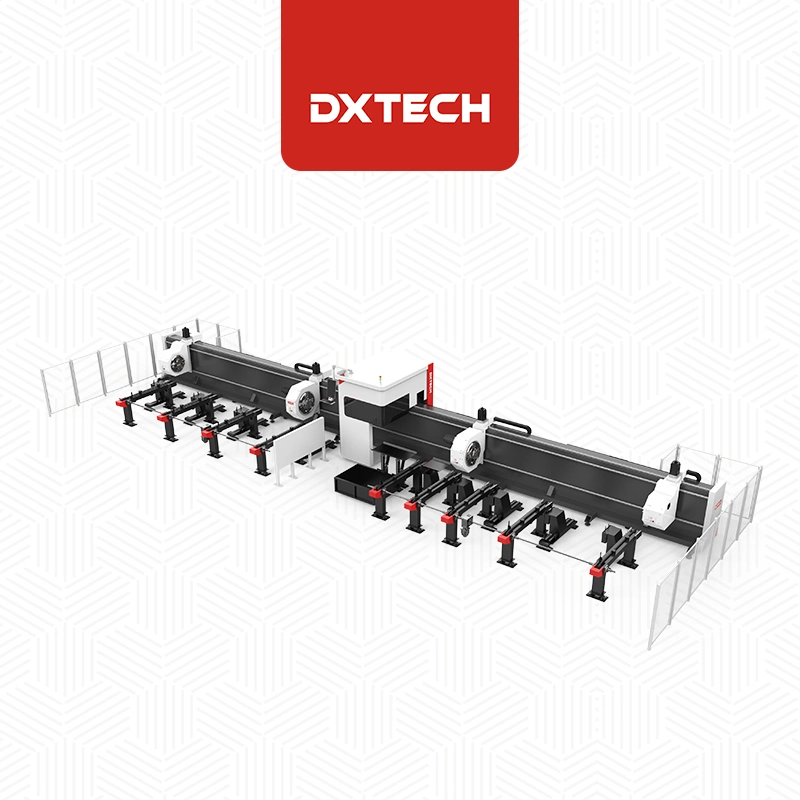

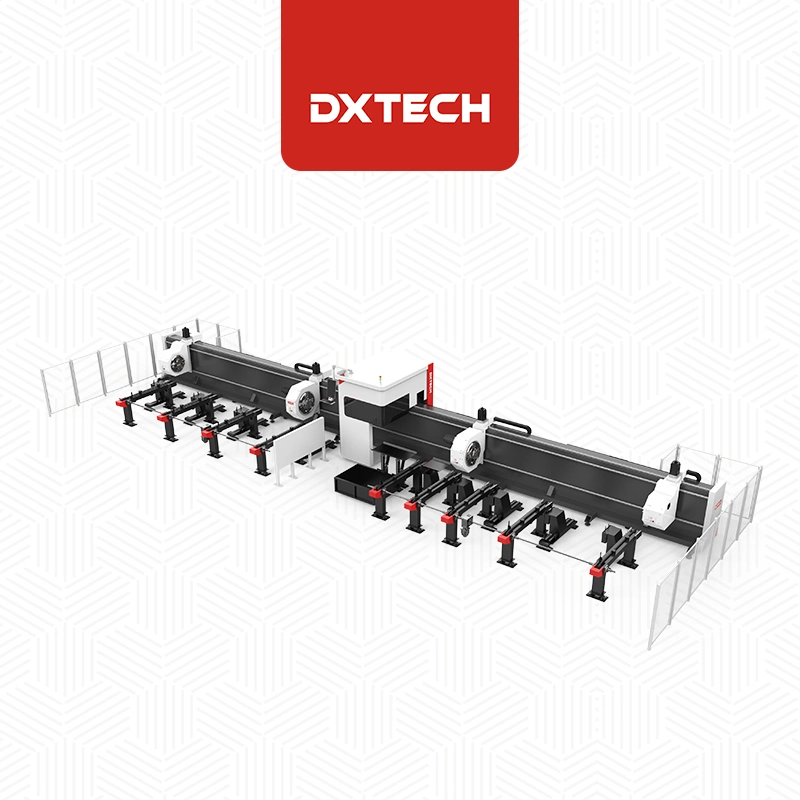

The TG-Series bevel tube laser cutting machine is specially designed for high-volume cutting of pipes, and it is more efficient than ordinary laser systems in cutting pipes and tubular metals. Tubes and rectangular tubes can be fed fully automatically without manual operation. The deformed tube can realize manual semi-automatic feeding. It is suitable for cutting round pipes, square pipes, rectangular pipes, waist pipes, angle steel, channel steel, I-beam and other special-shaped metal pipes. Fast corner response greatly improves cutting efficiency. After the workpiece is cut, it can be automatically unloaded by area.

Features

Product Parameters

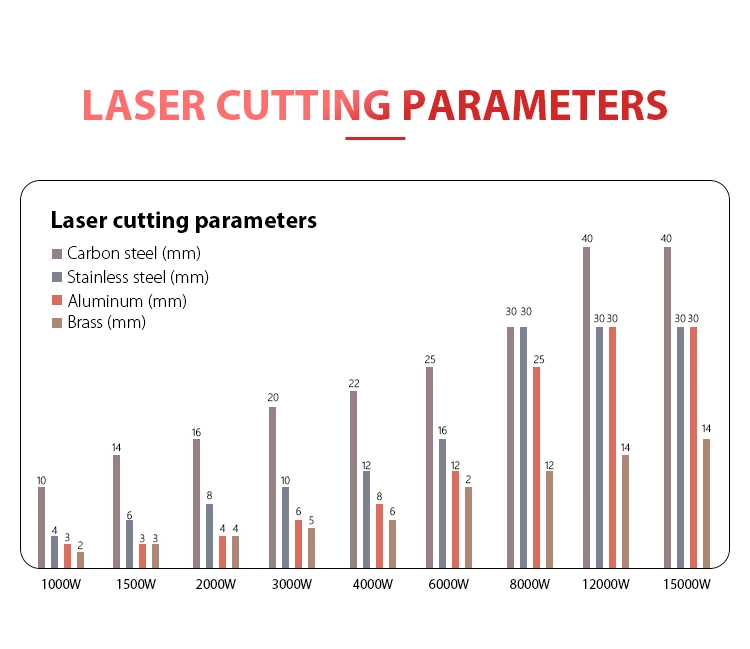

Cutting materials and thickness

The TG-Series bevel tube laser cutting machine is specially designed for high-volume cutting of pipes, and it is more efficient than ordinary laser systems in cutting pipes and tubular metals. Tubes and rectangular tubes can be fed fully automatically without manual operation. The deformed tube can realize manual semi-automatic feeding. It is suitable for cutting round pipes, square pipes, rectangular pipes, waist pipes, angle steel, channel steel, I-beam and other special-shaped metal pipes. Fast corner response greatly improves cutting efficiency. After the workpiece is cut, it can be automatically unloaded by area.

1. Automatic loading and unloading system

Loading and unloading are carried out synchronously, without unnecessary downtime, and the pipes will not collide with each other and will not be deformed.

2. Four pneumatic chucks

Large clamping force, automatic centering of the chuck, easy and stable clamping of heavy pipes.

3. Bevel cutting, high efficiency

Equipped with a professional bevel cutting head, supporting high-speed cutting of 0-45 degree bevel

Product Parameters

| Model | DXTECH-T6160/T9160 | DXTECH-T6220/T9220 |

| Max. tube length | 6.5m/9.2m | 6.5m/9.2m |

| Tube shape | Round/square/rectangular | Round/square/rectangular |

| Max. tube weight | 100kg 16kg/m | 200kg 30kg/m |

| Positioning accuracy | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm |

| Chuck | Two pneumatic chucks | Two pneumatic chucks |

| Max. chuck rotating speed | 130r/min | 130r/min |

| Laser power | 1kW - 4kW | 1kW - 4kW |

| Laser | Multiple options | Multiple options |

| Servo motor and driver | YASKAWA/FUJI | YASKAWA/FUJI |

| Reducer | Shimpo | Shimpo |

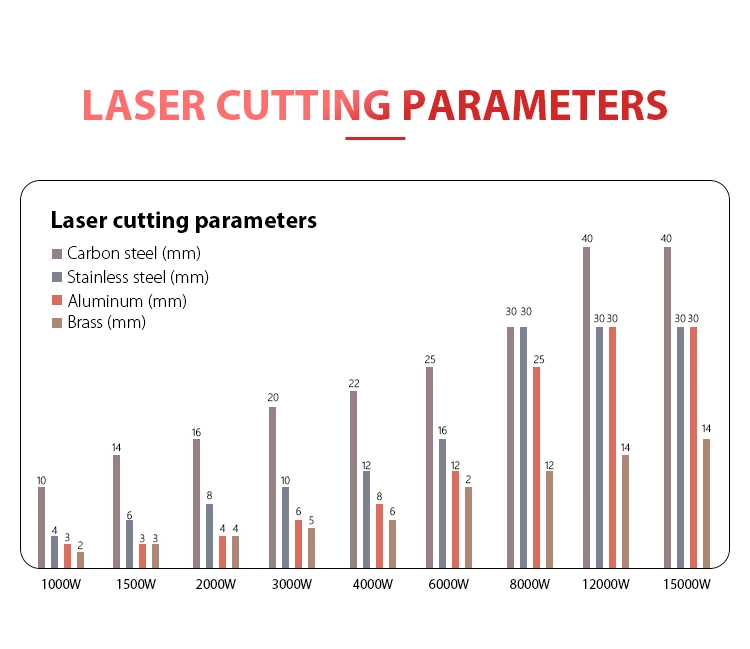

Cutting materials and thickness

| Carbon steel | 0.4-6mm | 0.4-10mm | 0.4-12mm | 0.4-14mm | 0.4-16mm | 0.4-20mm |

| Stainless steel | 0.4-3mm | 0.4-4mm | 0.4-5mm | 0.4-6mm | 0.4-8mm | 0.4-10mm |

| Aluminum | 0.4-2mm | 0.4-3mm | 0.4-3mm | 0.4-4mm | 0.4-6mm | 0.4-8mm |

| Brass | 0.4-3mm | 0.4-3mm | 0.4-3mm | 0.4-8mm | ||

| Laser power | 500w | 750w | 1000w | 1500w | 2000w | 3000w |