- Overview

- Product Description

- Packing and Shipping Details

- About HYT

- FAQ

Basic Info.

Product Description

Jiangsu HYT never guarantees our customers can enjoy the lowest price among the industry because that price could be unrealistic in most cases.

Jiangsu HYT only guarantee, here, you can find steel pipes whose quality and quantity is exactly as you want or the most reliable and suitable factory which can produce steel pipes as you wish. You, as well, will enjoy relatively cost-effective solution on the premise that quality and quantity are guaranteed. ASTM A513 Carbon Steel Mechanical Tubing

ASTM A513 Carbon Steel Mechanical Tubing

Commercial and residential products require a tough and durable metal tubing structure that supports the ruggedness of their applications. Highly durable ASTM A513 carbon steel from Jiangsu HYT provides robust structural support for the heavy-duty metal products that consumers utilize every day.

Jiangsu HYT stocks A513-1 as welded mechanical steel tubing and A513-5 DOM mechanical steel tubing in various sizes and shapes. The ASTM A513 specification covers electric-resistance-welded carbon steel tubing for use as mechanical and ornamental tubing.

Contact us for more information regarding premium A513 carbon steel mechanical tubing and we will gladly discuss the specific requirements of your next project.

Jiangsu HYT is your premium resource for advanced quality A 513 structural carbon steel tubing.

The types of tubing covered here are:

Type 1a, as-welded from hot-rolled steel (with mill scale);

Type 1b, as-welded from hot-rolled pickled and oiled steel (mill scale removed);

Type 2, as-welded from cold-rolled steel;

Type 3, sink-drawn hot-rolled steel;

Type 4, sink-drawn cold-rolled steel;

Type 5, drawn over a mandrel;

Type 6, special smooth inside diameter.

| Product Name | A513 Carbon and Alloy Steel Mechanical Tubing | |

| Process | ERW | |

| Shape | Round, square, rectangular and special shape | |

| Size Range (round tubing) | ERW tubing from hot rolled steel | OD: 1/2 ~ 15 inch (19.0 ~ 381.0 mm) WT:0.065 ~ 0.650 inch (1.65 ~ 16.50 mm) |

| ERW tubing from cold-rolled steel | OD: 3/8 ~ 12 inch (9.92 ~ 304.8 mm) WT: 0.022 ~ 0.134 inch (0.71 ~ 3.40 mm) | |

| Grade | 1008 1009 1010 1012 1015 1016 1017 1018 1019 1020 1021 1022 1023 1024 1025 1026 1027 1030 1033 1035 1040 1050 1060 1340 1524 4118 4130 4140 5130 8620 8630 | |

A513 Carbon Steel Mechanical Tubing Benefits

A513 carbon steel tubing products provide numerous advantageous qualities to a wide range of consumer and commercial industrial companies throughout the world. Some of the most distinct beneficial qualities that A513 Carbon Steel Mechanical Tubing provides includes:

A513 Tubing Advantages

-Works to tight tolerances

-Consumer product applicable

-Less costly

-Durable

A513 Carbon Steel Mechanical Tubing Specifications & Requirements

ASTM A513 specifications state that manufactured carbon steel tubing must meet certain specifications before being sold for any type of project. The A 513 carbon steel spec sheet provides an accessible and straightforward way to check material standards before beginning your next project.

ASTM A513 Steel Properties

A513 carbon steel mechanical tubing is only manufactured from materials that match the criteria for carbon steel. The chemical composition for A513 is mostly iron with added carbon, manganese, phosphorus, silicon, and silver. Check out the chart below for exact A513 carbon steel chemical specifications.

Chemical Requirements

| Grade Designation | Chemical Composition Limits, % | |||

| Carbon | Manganese | Phosphorus, max | Sulfur, max | |

| 1010 | 0.05-0.15 | 0.30-0.60 | 0.035 | 0.035 |

| 1015 | 0.10-0.20 | 0.30-0.60 | 0.035 | 0.035 |

| 1020 | 0.15-0.25 | 0.30-0.60 | 0.035 | 0.035 |

| 1026 | 0.22-0.28 | 0.60-0.90 | 0.035 | 0.035 |

A513 Properties

Tensile strength refers to the amount of stretching stress a material can withstand before breaking or failing. The ultimate tensile strength of A513 carbon steel is calculated by dividing the area of the steel by the stress placed on it, which is expressed in terms of pounds or tons per square inch of material. Tensile strength is also an important measure of A513's ability to perform in an application. A513 carbon steel's tensile strength is described in the chart below.

Hardness Limits and Tensile Properties for Round Tubing

| Yield Strength, Ksi (MPa), min | Ultimate Strength, ksi (MPa), min | Elongation in 2 in. or 50 mm. % min | RB min | RB max | |

| As-Welded Tubing | |||||

| 1008 | 30(207) | 42 (290) | 15 | 50 | |

| 1010 | 32(221) | 45 (310) | 15 | 55 | |

| 1015 | 35(241) | 48 (331) | 15 | 58 | |

| 1020 | 38(262) | 52 (359) | 12 | 62 | |

| 1026 | 45(310) | 62 (427) | 12 | 68 | |

| Normalized Tubing | |||||

| 1008 | 23 (159) | 38 (262) | 30 | 65 | |

| 1010 | 25 (172) | 40 (276) | 30 | 65 | |

| 1015 | 30 (207) | 45 (310) | 30 | 70 | |

| 1020 | 35 (241) | 50 (345) | 25 | 75 | |

| 1026 | 40 (276) | 60 (414) | 25 | 85 | |

| Sink-Drawn Tubing | |||||

| 1008 | 38 (262) | 38 (262) | 8 | 65 | |

| 1010 | 40 (276) | 40 (276) | 8 | 65 | |

| 1015 | 45 (310) | 45 (310) | 8 | 67 | |

| 1020 | 50 (345) | 50 (345) | 8 | 70 | |

| 1026 | 55 (379) | 55 (379) | 7 | 77 | |

| Mandrel-Drawn Tubing | |||||

| 1008 | 50 (345) | 60 (414) | 5 | 73 | |

| 1010 | 50 (345) | 60 (414) | 5 | 73 | |

| 1015 | 55 (379) | 65 (448) | 5 | 77 | |

| 1020 | 60 (414) | 70 (483) | 5 | 80 | |

| 1026 | 70 (483) | 80 (552) | 5 | 85 | |

| Mandrel-Drawn Stress-Relieved Tubing | |||||

| 1008 | 45 (310) | 45 (310) | 55 (379) | 12 | 68 |

| 1010 | 45 (310) | 45 (310) | 55 (379) | 12 | 68 |

| 1015 | 50 (345) | 50 (345) | 60 (414) | 12 | 72 |

| 1020 | 55 (379) | 55 (379) | 65 (448) | 10 | 75 |

| 1026 | 65 (448) | 65 (448) | 75 (517) | 10 | 80 |

ASTM A513 Carbon Steel Permissible Variations in Dimensions (Wall Thickness)

Permissible variations in wall thickness for A513-1 steel tubing are ±10% of the nominal wall. Permissible variations in wall thickness for A513-5 DOM are available by request. Contact Jiangsu HYT for more information.

ASTM A513 Steel Materials & Manufacturing

A513 mechanical steel tubes from Jiangsu HYT are manufactured via electric resistance welding, and can made from hot- or cold-rolled steel, as specified.

Contact Jiangsu HYT for ASTM A513 Steel Tubing Today

Contact us for more information regarding ASTM A 513 steel mechanical tubing specifications and product options, or request a quote for further pricing details today.

Jiangsu HYT is your trusted source for premium ASTM A513 carbon steel tubing products.

Steel Pipe Package and Delivery Details

Port | Shanghai, Tianjin, Qingdao |

Package | (a) tubes bound with a steel band, (b) tubes wrapped in plastic sheets, burlap, (c) tubes in wooden crates. (or as customers' demands) |

Marking | (a) without marking, (b) marked with colored stripes on the tubes (tube bundles), (c) marked with spray either by a white or black color using Inkjet (d) marked by stamping the data (this applies to OD > 22 mm and WT >2.3 mm). |

Surface Protection | Inter paper available PVC protecting film available Tip: While ordering, it is necessary to agree upon the methods and means of temporarily protecting the surface of the tubes during transportation and storage. |

Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

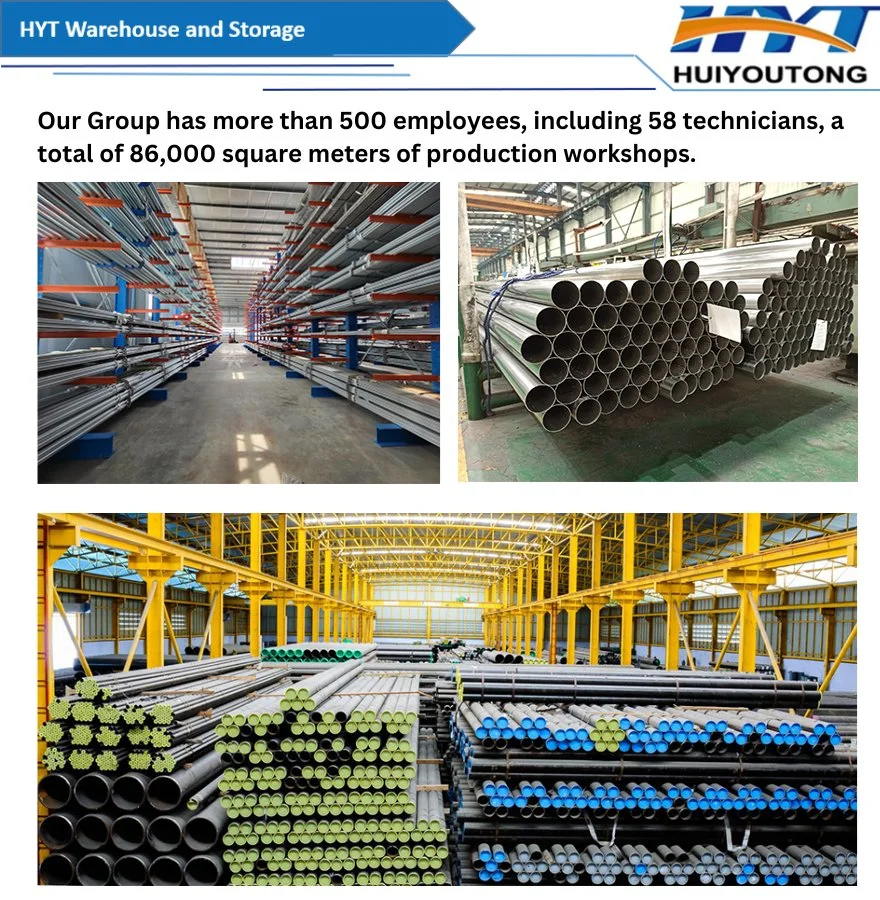

Jiangsu HYT, founded in 2015, is a wholly-owned subsidiary of WuxiLusheng Special Steel Co, Ltd which is responsible for overseassales and market exploitation of various kinds of steel pipes.

Jiangsu HYT, founded in 2015, is a wholly-owned subsidiary of WuxiLusheng Special Steel Co, Ltd which is responsible for overseassales and market exploitation of various kinds of steel pipes.

Our Group, certified by ISO and SGS, is a high-tech enterprise integrating research, development, production and sales of steel pipesmade of stainless steel, carbon steel and alloy steel. HYT owns independent steel pipe factories with 50+ high precision cold drawingand cold rolling production lines, which can meet customers' requirements on the quality, quantity, precision and customization of steel pipes. Only a Widely Recognized Company can be Trusted by Our Customers

Only a Widely Recognized Company can be Trusted by Our Customers

HYT always believes that various certifications can prove the strength and reliability of a company more than words. HYT actively accepts qualification audits from various official or industry organizations to relieve customers from worries. We believe these will help us serve our customers better.

Since 2015, HYT has actively cooperated with many domestic steel mills. HYT regularly exchange steel technology with these mills and make progress from this. ln the process of communicating with customers, we carefully listen to customers' requirements and produce steel products as customers' demands. Under necessary circumstances, HYT is willing to help customers find suitable steel mill to produce some special products to save time and cost for customers because we have the reliable resources of still mills to prevent you to be cheated. Obtaining Customers' Trust is Our Focus

Obtaining Customers' Trust is Our Focus

Our Group provides customers with high-quality products and services with advanced equipment, strong technical strength and a high sense of social responsibility. Since 2015, Our products have been exported globally, including Germany, France, the United States, Japan, Russia, ltaly, Turkey, the United Arab Emirates, Australia, Saudi Arabia, Ukraine, Thailand, Viet-nam, Singapore, Spain, lreland, India, South Africa, Mexico, etc.

We sincerely hope to establish a long-term and extensive strategic partnership with ourcustomers for mutual benefit and common development!

Old Customers' Feedback is HYT Precious Treasure

We also properly save some past conversation screenshot(Customers' names are coded toprotect privacy) to record the feedback of our old customers when they have used HYT steel pipe. HYT pays more attention to customers' feedback because we trust only in this way can we know the pain spot of steel pipe industry and better serve our customers.

FAQ

Accepted Payment Terms: T/T, L/C, D/P, etc.

Yes, we can produce customized products exactly as your specification and CAD drawing.