Basic Info.

Model NO.

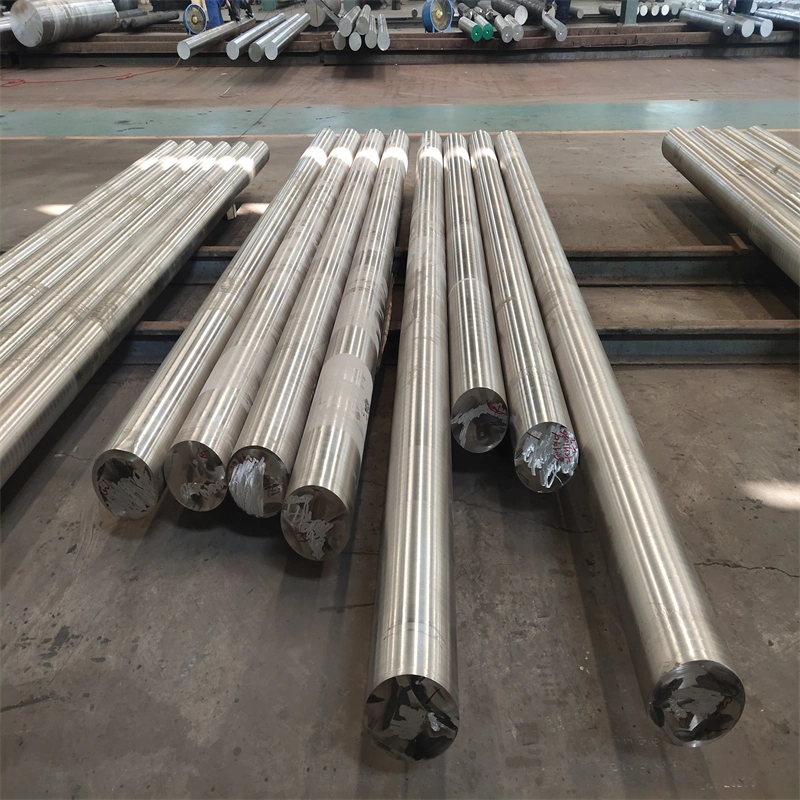

SCM420

Special Use

Alloy Structural Steel

Application

Structural Steel Bar

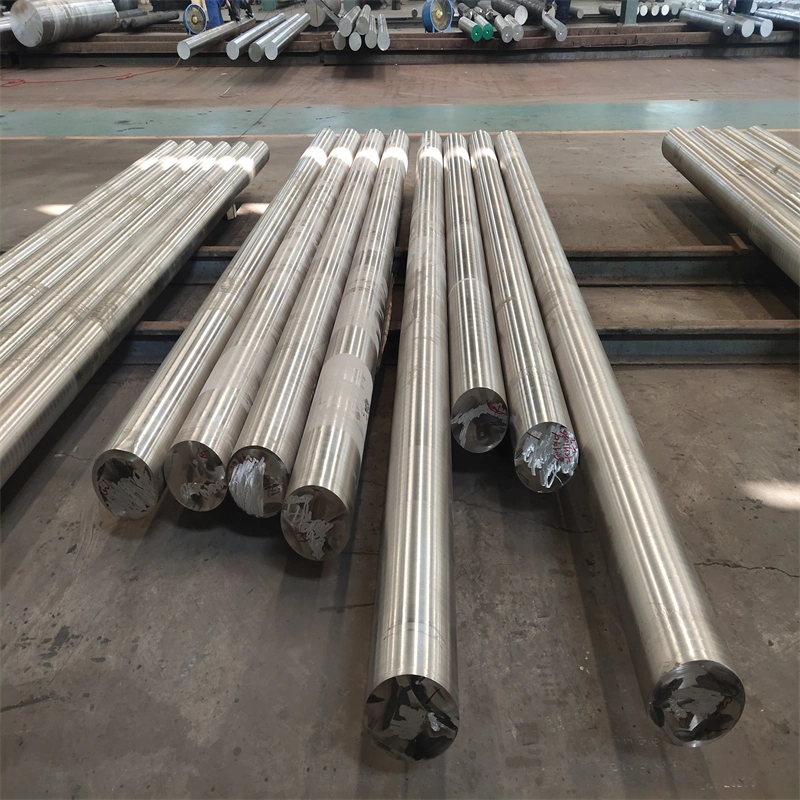

Size Range

Round Bar:Dia12~420mm Flat Bar:2~420 X 30~1500mm

Smelting Process

Ef, Eaf, ESR

Delivery Condition

Hot Rolled, Forged, Annealed,Quenched and Tempered

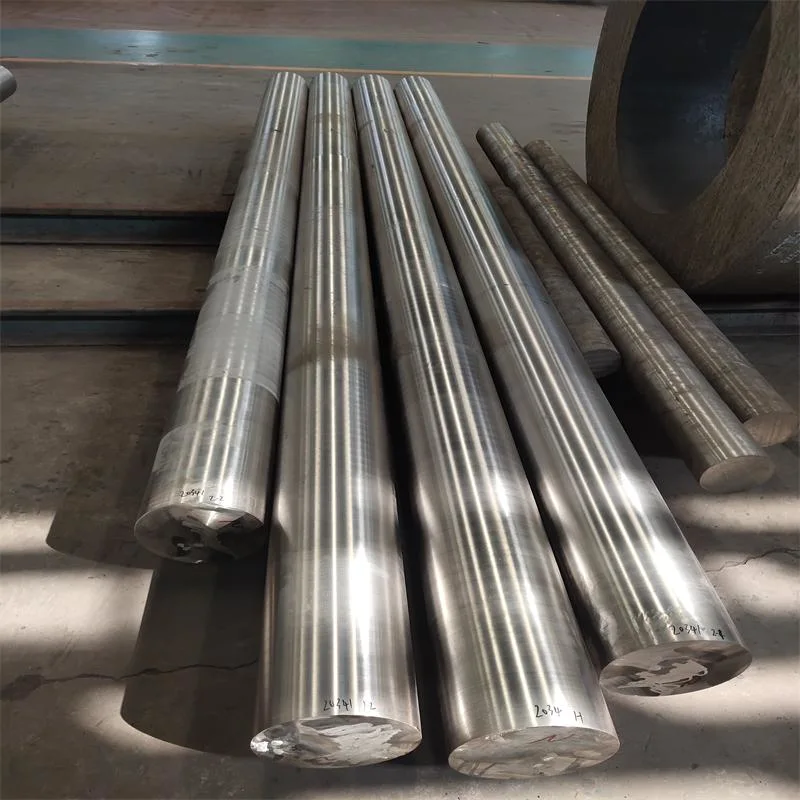

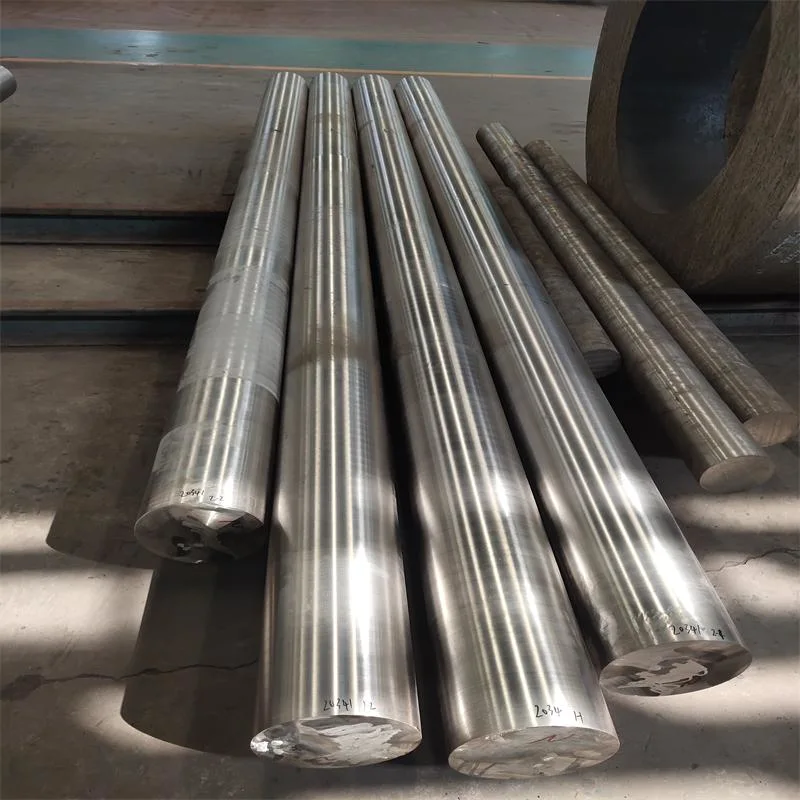

Surface Condition

Black Surface, Grinded,Peeled,Milled,Polished

Transport Package

Seaworth Packing

Specification

Round Bar: Dia12~420mm Flat Bar: 2~420 X 30~1500mm

Trademark

FUSHUN

Origin

, Hubei

HS Code

7228100000

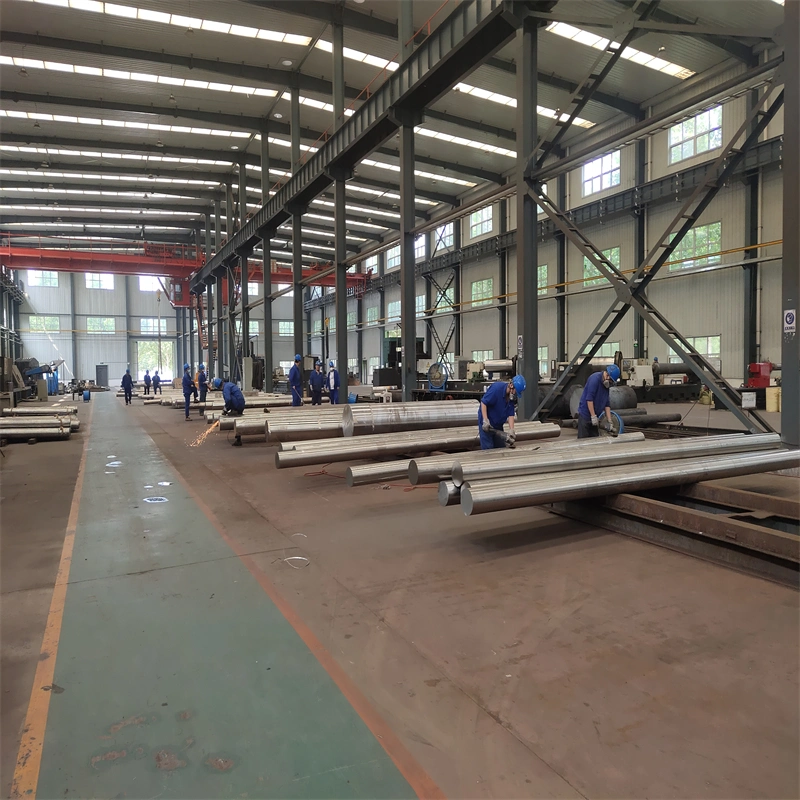

Production Capacity

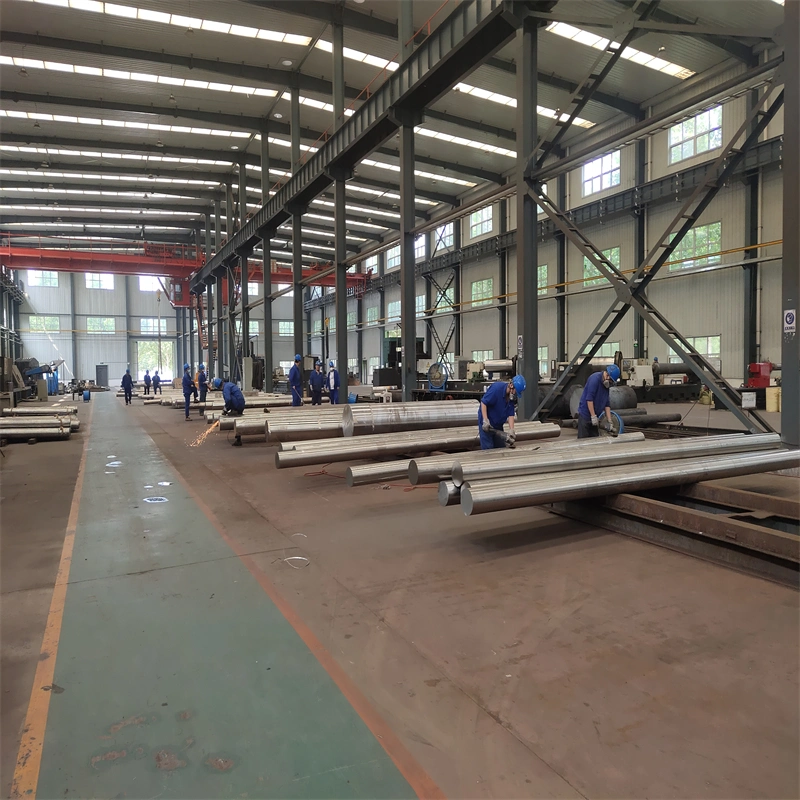

5000tons/Year

Product Description

Size available:

Square/Round Bar: 12~ 500mm

Flat:10~155 x 50~ 800mm

Steelmaking process: EF, EF/EAF+LF+VD, EF/EAF+ESR, hot forged/ hot rolled

Delivery condition: hot rolled, forged, annealed, quenched and tempered ,or as your special requirements.

Surface condition: black surface, polished surface, grinded surface, peeled surface, milled surface.

Packing details:In seaworthy packing, as your requirement.

Delivery details:within 30-50 days

Chemical composition(%):

C 0.18~0.23 Si 0.15-0.35 Mn 0.60-0.85 P 0.030max. S 0.030max. Cr 0.90~1.20 Ni 0.25Max. Mo 0.15-0.30 Cu 0.30max.

Mechanical Properties:

Tensile Strength (MPa):930

Elongation (%):14

Reduction of Area (%):40

Impact Akv (J):59

Hardness (HB):262-352

Marking: Grade, heat NO. length will be stamped on each bar with required color.

Ultrasonic Test:Material will be ultrasonically tested at appropriate stages of the manufacture

to ensure the quality, as agreed between seller and purchaser.

Quality assurance: ISO9001 certified, IQNet, CQC.

Square/Round Bar: 12~ 500mm

Flat:10~155 x 50~ 800mm

Steelmaking process: EF, EF/EAF+LF+VD, EF/EAF+ESR, hot forged/ hot rolled

Delivery condition: hot rolled, forged, annealed, quenched and tempered ,or as your special requirements.

Surface condition: black surface, polished surface, grinded surface, peeled surface, milled surface.

| Features: Competitive price immediate delivery Premium quality Reliable service |

Packing details:In seaworthy packing, as your requirement.

Delivery details:within 30-50 days

Chemical composition(%):

C 0.18~0.23 Si 0.15-0.35 Mn 0.60-0.85 P 0.030max. S 0.030max. Cr 0.90~1.20 Ni 0.25Max. Mo 0.15-0.30 Cu 0.30max.

Mechanical Properties:

Tensile Strength (MPa):930

Elongation (%):14

Reduction of Area (%):40

Impact Akv (J):59

Hardness (HB):262-352

Marking: Grade, heat NO. length will be stamped on each bar with required color.

Ultrasonic Test:Material will be ultrasonically tested at appropriate stages of the manufacture

to ensure the quality, as agreed between seller and purchaser.

Quality assurance: ISO9001 certified, IQNet, CQC.