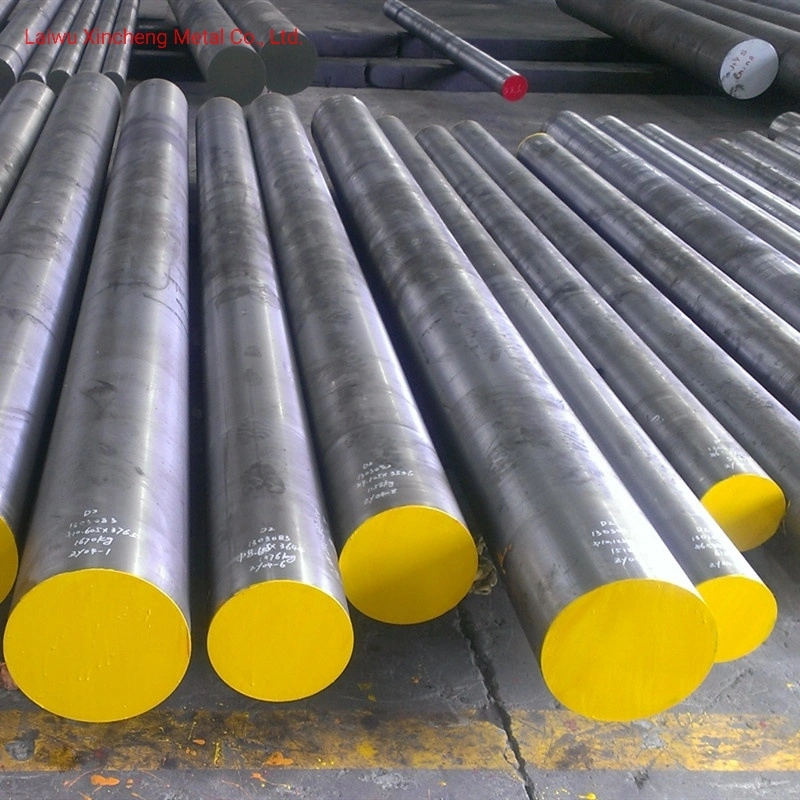

Product Description

1.About AISI 8620 Forged Alloy Steel Bars:

AISI 8620 Steel is a low alloy nickel, chromium, molybdenum case hardening steel, generally supplied in the as rolled condition with a maximum hardness HB 255max. SAE steel 8620 offers high external strength and good internal strength, making it highly wear resistant. AISI 8620 steel has a higher core strength than grades 8615 and 8617.

SAE 8620 alloy steel is flexible during hardening treatments, thus enabling improvement of case/core properties. Pre hardened and tempered (uncarburized) 8620 can be further surface hardened by nitriding but will not respond satisfactorily to flame or induction hardening due to its low carbon content.

Steel 8620 is suited for applications which require a combination of toughness and wear resistance. This grade is commonly supplied in round bar.

2. SAE 8620H / SAE 8620Steel Specification and Relevant Standards

| Country | USA | DIN | BS | BS | Japan |

| Standard | ASTM A29 | DIN 1654 | EN 10084 | BS 970 | JIS G4103 |

| Grades | 8620 | 1.6523/ | 1.6523/ | 805M20 | SNCM220 |

| 21NiCrMo2 | 20NiCrMo2-2 |

3. SAE 8620H / SAE 8620 Steel Equivalent and chemical composition

| Standard | Grade | C | Cr | Ni | Mo | Si | Mn | P | S |

| GB/T 5216 | 20CrNiMoH | 0.17-0.23 | 0.35-0.65 | 0.35-0.75 | 0.15-0.25 | 0.17-0.37 | 0.6-0.95 | 0.035 | 0.035 |

| JIS G4052 | SNCM220H | 0.17-0.23 | 0.35-0.65 | 0.35-0.75 | 0.15-0.25 | 0.15-0.35 | 0.6-0.95 | 0.03 | 0.03 |

| ASTM A304 | 8620H | 0.17-0.23 | 0.35-0.65 | 0.35-0.75 | 0.15-0.25 | 0.15-0.35 | 0.65-0.95 | 0.025 | 0.025 |

| EN10084 | 20NiCrMo2 | 0.17-0.23 | 0.35-0.7 | 0.4-0.7 | 0.15-0.25 | 0.4 | 0.65-0.95 | 0.035 | 0.035 |

4.Forging of Material 8620 Steel

AISI 8620 alloy steel is forged at a start temperature of around 2250ºF (1230ºC) down to approximately 1700ºF(925ºC.) prior to the hardening heat treatment or carburizing. The alloy is air cooled after forging.

5.Forged Steel Size we can supply:

| Forged Steel Round Bar | Φ85mm~1200mm |

| Forged Square steel Bar: | 150×150-800×800mm |

| Forged Flat Blocks: | (150mm-800mm)*(200mm-800mm) |

| Forged Shaft and Forged Ring | According to Customer's drawing |

5.Inspecting:

UT according toSEP1921 C/c, D/d, E/e, A388 or GB/T 6402,

Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,

6.Delivery Condition:

Forged+black surface

Forged+rough machined

Forged+rough turned+QT/annealed/normalized

Surface condition: Black; Peeled; Polished; Machined; Grinded; Turned; Milled

7.Manufacture:EAF+LF+VD(Annealed,normalized,Quenched+Tempered,peeled,rough turned).

8.Heat Treatment: Normalized / Annealed / Quenched / tempered (optional)

Main Grade we can supply for forged steel bars

| Steel series | Representative steel type |

| Carbon Steel series | AISI 1020,1045,A36,S355JR,S355JO |

| Petroleum machinery series | AISI4150,AISI4140,AISI4130, |

| 30CrMo,4145H | |

| Tool mold series | 1.2714,5CrMnMo,5CrNiMoV, |

| 1.2738,1.2311,1.2312 1.2714 H13 | |

| Bearing series | 52100,GCr15,SUJ2 |

| Marine series | 4140,42CrMo,SCM440, |

| 709M40 | |

| Car series | SAE8620,20CrNiMo, |

| SNCM220 | |

| Heavy-duty transmission series | 40CrNiMo,SNCM439, |

| SAE4340,EN24 | |

| Mining machinery series | 655M13,826M40, |

| 25CrMo | |

| Wind power gear series | 18CrNiMo7-6, 17CrNiMo6, 1.6582,1.6587,SAE8620 |

| Wind power spindle series | 34CrNiMo6,817M40 |

| Nitriding series | 20MnCr5,38CrMoAl, |

| 31CrMoV9 | |

| Pressure vessel series | 15CrMo,13CrMo4-4 |

| Metallurgical roll series | 21CrMoV511,W1.7225, |

| EN19,709M40 |

About our factory:

Our main products include Forged Steel Round Bar from Sizes 85mm to 1100mm, Forged Steel Square Bar from Sizes 150×150 to 800×800mm with various grade ;The largest production steel ingot 15T, mainly forged alloy steel, carbon steel and other materials. The annual output of forged round can reach 60,000 tons. The products are widely used and can be supplied to users in metallurgy, chemical, hydraulic, port and marine machinery The main equipment includes a 2000-ton hydraulic press, a 3-ton electro-hydraulic hammer, a 2.5-meter ring rolling machine, and is equipped with large and small traveling machines, metalworking lathes, and multiple large and small sawing machines. The company now has more than 100 sets of production equipment from a whole set of processes from blanking, heating, forging to heat treatment and machining.