Product Description

Stainless steel round bar 431 SUS431 X22CrNi17 431S29

431 is martensitic stainless steel and 430 is ferritic stainless steel. The difference in elemental content between the two is not very large, mainly 431 contains 1.25%-2.5% nickel, and 430 does not. The elemental composition of these two materials is as follows:

Elemental composition of 431 stainless steel: (carbon) C0.2, (manganese) Mn1.0, (phosphorus) P0.04, (sulfur) S0.03, (silicon) Si1.00, (chromium) Cr15~17. (Nickel) Ni1.25~2.5.

Elemental composition of 430 stainless steel: (carbon) C0.12, (manganese) Mn1.0, (phosphorus) P0.04, (sulfur) S0.03, (silicon) Si1.00, (chromium) Cr16~18.

431 stainless steel, name: martensitic stainless steel. 431 (16Cr-2Ni) Ni-containing Cr steel can obtain high mechanical properties by heat treatment, and its corrosion resistance is better than 410 steel and 430 steel. 431 stainless steel corresponds to China 1Cr17Ni2, Japan JIS SUS431.

The 1Cr17Ni2 system is a kind of steel with good strength and toughness in martensitic stainless steel. It has good corrosion resistance to aqueous solutions of oxidizing acids, most organic acids and organic salts. Generally suitable for the production of nitric acid, acetic acid production and light industry, textile and other industries require strong toughness and corrosion resistance of shafts, piston rods, pumps and other parts.

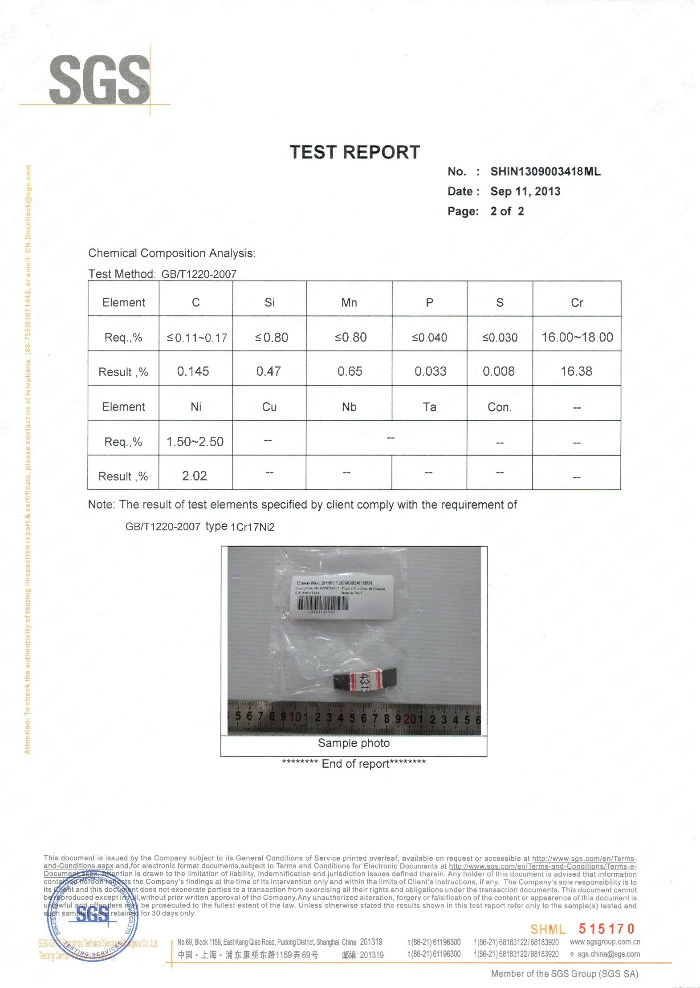

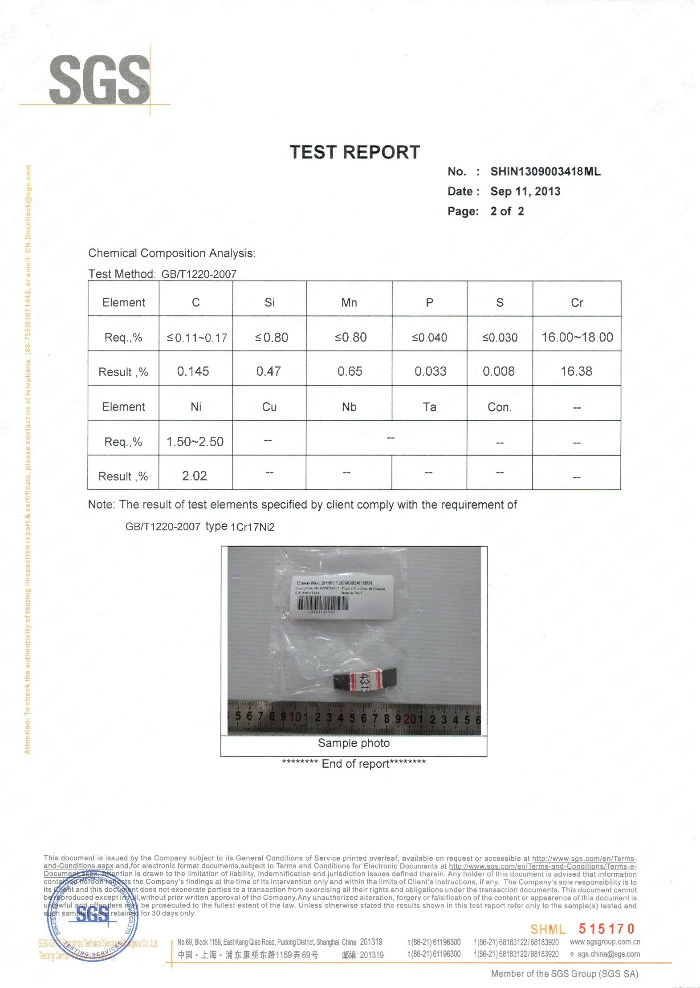

Test Report and SGS Report:

Payment Terms:

431 is martensitic stainless steel and 430 is ferritic stainless steel. The difference in elemental content between the two is not very large, mainly 431 contains 1.25%-2.5% nickel, and 430 does not. The elemental composition of these two materials is as follows:

Elemental composition of 431 stainless steel: (carbon) C0.2, (manganese) Mn1.0, (phosphorus) P0.04, (sulfur) S0.03, (silicon) Si1.00, (chromium) Cr15~17. (Nickel) Ni1.25~2.5.

Elemental composition of 430 stainless steel: (carbon) C0.12, (manganese) Mn1.0, (phosphorus) P0.04, (sulfur) S0.03, (silicon) Si1.00, (chromium) Cr16~18.

431 stainless steel, name: martensitic stainless steel. 431 (16Cr-2Ni) Ni-containing Cr steel can obtain high mechanical properties by heat treatment, and its corrosion resistance is better than 410 steel and 430 steel. 431 stainless steel corresponds to China 1Cr17Ni2, Japan JIS SUS431.

The 1Cr17Ni2 system is a kind of steel with good strength and toughness in martensitic stainless steel. It has good corrosion resistance to aqueous solutions of oxidizing acids, most organic acids and organic salts. Generally suitable for the production of nitric acid, acetic acid production and light industry, textile and other industries require strong toughness and corrosion resistance of shafts, piston rods, pumps and other parts.

- Corresponding national brands

- Corresponding Japanese brand: SUS431

- Corresponding to the German brand: X22CrNi17

- Corresponding to the US brand: 431

- Corresponding British brand: 431S29

- Mechanical properties: tensile strength σb (MPa): quenching and tempering, ≥1080 elongation δ5 (%): quenching and tempering, ≥10 impact energy Akv (J): quenching and tempering, ≥39 hardness: annealing, ≤285HB

- Heat treatment specifications and metallographic organization: heat treatment specifications: 1) annealing, high temperature tempering air cooling at 680 to 700 °C; 2) quenching, oil cooling at 950 to 1050 °C; 3) tempering at 275 to 350 °C. Metallographic organization: The tissue is characterized by martensite type.

- Delivery status: Generally delivered in heat treatment state, the type of heat treatment is indicated in the contract; if not specified, it is delivered in the state without heat treatment.

Test Report and SGS Report:

Payment Terms:

| Lead Time | 10-15 Days | ||||

| Port of Shipment | Shanghai Port | ||||

| Payment Terms | 30% T/T as deposit, balance before shipment | ||||

| Price of Validity | 5.0 Days |