Basic Info.

Model NO.

steel bar

Special Use

Cold Heading Steel, Mold Steel

Application

Structural Steel Bar

Forged Steel Bar

Forged Steel Block

Forged Square Bar

Forged Pipe

Heat Treatment

Yes

Delivery Time

20-30days

Raw Material

Steel Billet or Steel Ingot

Transport Package

Seaworhty Packaging

Specification

200mm-1000mm

Trademark

Shandong

Origin

China

Production Capacity

5000tons

Product Description

4140 SCM440 42CrMo4 1.7225 Hot Forged Alloy Steel Bar

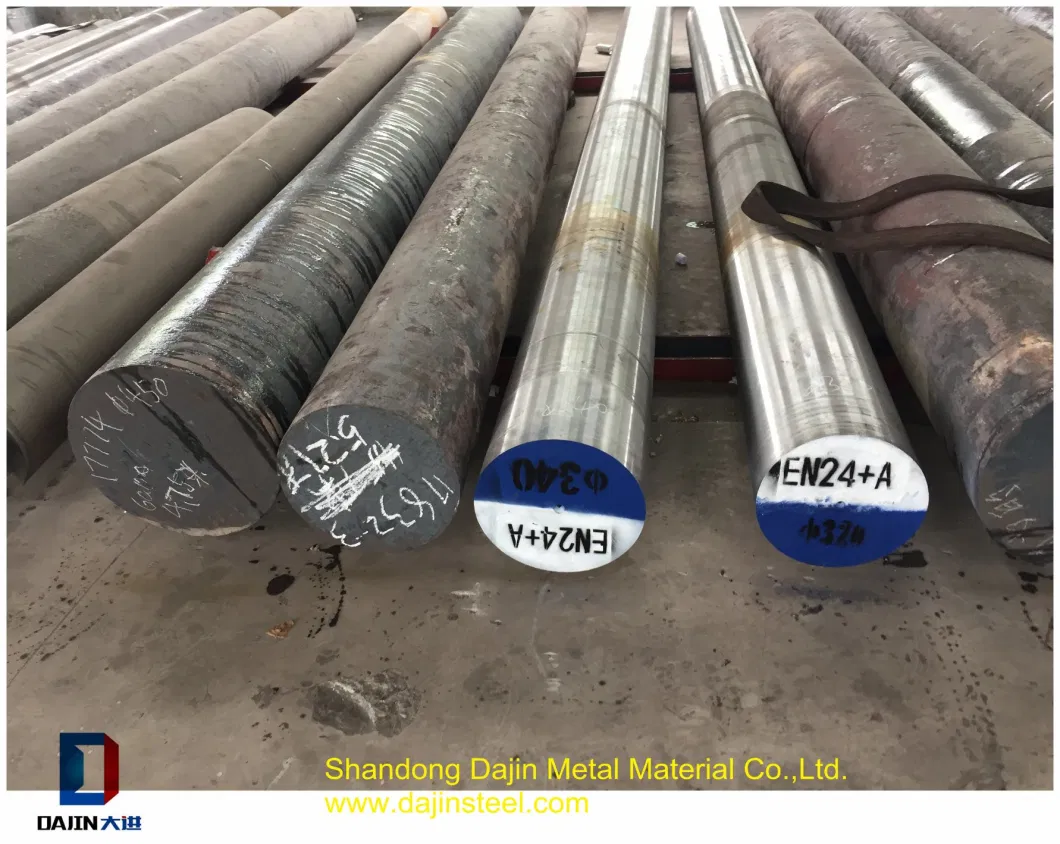

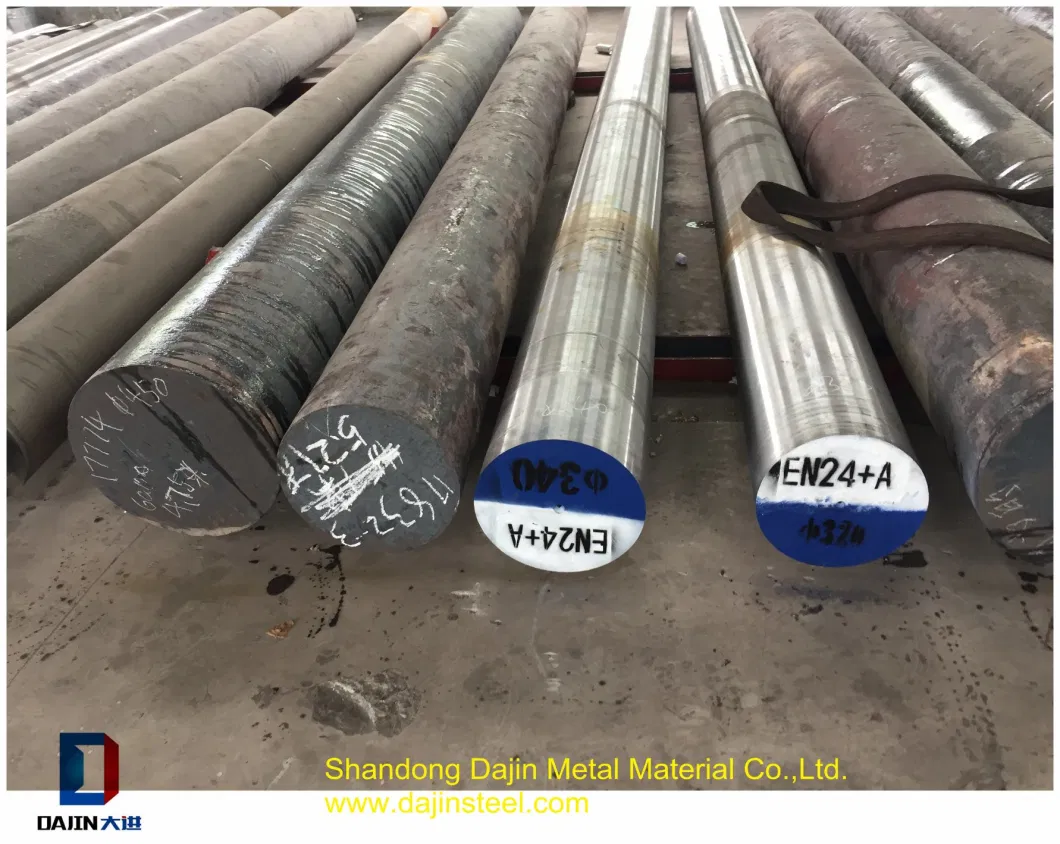

Forged alloy round steel bar EN24 EN19 4340 42Crmo4 4150steel forging/forging round steel bar/

alloy steel forging bar

| C | Si | Mn | P | S | Cr | Ni | Mo |

| 0.38/0.43 | 0.15/0.35 | 0.65/0.85 | <=0.025 | <=0.025 | 0.7/0.9 | 1.65/2.0 | 0.2/0.3 |

Process: Forged from vacuum degassed ingots.

Shape: Round /Square/Plat/shaft/block

| Similar grade in different standard | SAE4140/1.7225/SCM440/42CrMo4/42CrMo |

| Available sizes | Forged steel round bar:200mm-800mm Forged steel square:block200mm*200mm-500mm*500mm Forged steel flat block (150mm-500mm)*(200mm-500mm) Forged Shaft:according to client's drawing,we also can supply drawing according to client's requirement |

| Production Process | EAF+LF+VD ( necessary) +forged+UT+ rough machined(optional) +UT+ Heat Treatment (optional)+UT+Precision machining |

| Delivery condition | Forged+black surface Forged+rough machined Forged+rough turned+QT/annealed/normalized |

| Heat treatment: | Normalized / Annealed / Quenched / tempered (optional) |

| Applications | Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears. |

| Inspection | Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,100% UT test according to :SEP1921-84,GR.3 CLASS C/c or D/d |

| Packing situation | standard seaworthy packing or as customer required |

| Delivery time | 7days for stock,30days for new material |

| Payment term | T/T or L/C |

| Our mill's certificates | ISO901&ISO.TS16949,ISO4001,OHSAS18001 Special Equipment Manufacturing License of P.R.C for pipeline plate,steel plate for boiler&Vessel; ISO/TS16949 2009;Europe CE Mark Certificate;JIS MARK,KS MARK. |

Factory Quality Control

PO=>Make production plan(By professional QA team)=>Select perfect raw material(100% checked by Metal Analyzer)=>Cut raw material(marking transfer)=>Heating&forged(production record to control the forge ratio=>HT after forged(Time&TEMP record)=>check black forged(grain size,UT&Sizes)=>rough machining(UT&Sizes)=>Heat treatment(controlled by computers)=>check mechanical property&hardness(universal testing machine&KING hardness tester)=>Semi finish machining(UT,MT&sizes)=>final check(all QC records)=>Packing&warehousing(all docs)=>delivery on time

Our advantage

- Computer-Aided Design (CAD) System

- Multiple Wire EDM (Electric Discharge Machining) Machines

- Plunge EDM (Solid Electrode Electric Discharge Machining)

- Complete Manufacturing of Carbide Dies

- Contoured Straightener Rolls

- Profile Shape Shear Knives

- Fast Tooling Changes and Modifications

- An Advanced Quality Planning System Used for Prototyping